Things You Need to Know About Lined Globe Control Valves

What Are Lined Globe Control Valves?

Definition and Purpose

Lined globe control valves are advanced industrial tools. They regulate fluid flow in pipelines. These valves have a protective inner coating. This coating is often made of PTFE or similar anti-corrosion materials. It shields against harsh chemicals and tough conditions. Their main goal is to ensure accurate flow control. They also provide durability and resist corrosion. This makes them ideal for handling corrosive or abrasive substances. Industries rely on these valves for safe and efficient operations.

Key Components

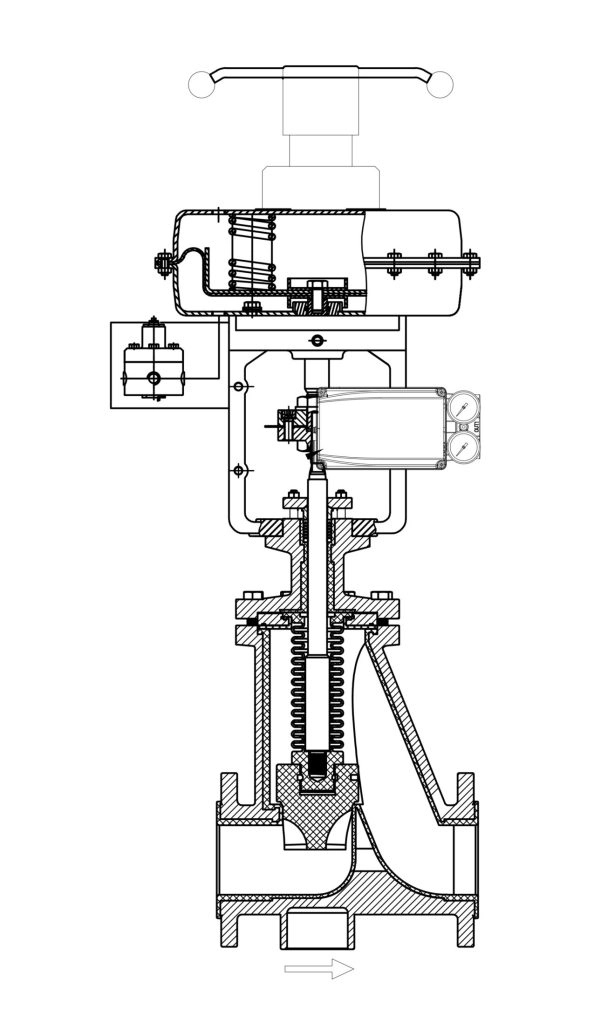

A lined globe control valve consists of several vital parts:

- Valve Body: The outer shell. It houses internal components. It ensures structural strength.

- Internal Lining: A protective layer inside. Made from materials like PTFE. It guards against chemical damage.

- Stem and Actuator: The stem connects to an actuator or handwheel. This allows the operator to adjust the valve disc. It enables precise flow control.

- Valve Disc: A movable part. It regulates or stops fluid flow by interacting with the seat.

- Seat: A fixed component. It forms a seal with the disc. This prevents leaks when the valve is closed.

Globe valves are linear motion valves. They serve both on-off and throttling functions. Their short travel ensures precise control. This makes them versatile in various industrial settings. They are widely used for their reliability and efficiency.

Advantages

Corrosion Resistance in Tough Conditions

Lined globe control valves excel in resisting corrosion. The inner lining acts as a barrier. It prevents fluid from reacting with the valve body. This avoids structural damage. These valves are perfect for industries dealing with acids, alkalis, or solvents. The lining ensures long-term protection. It maintains the valve’s integrity in harsh environments.

Enhanced Flow Control Accuracy

These valves are designed for precise flow adjustments. They allow accurate control of flow rates. This remains true even under varying pressures. Miwival offers various designs, such as T type, Y type, and angle type. These provide flexibility for specific applications. Operators can achieve optimal performance. The valves ensure consistent and reliable flow management.

Longevity and Durability

These valves combine strong materials with anti-corrosion linings. They withstand harsh conditions for extended periods. This reduces the need for frequent maintenance. It also extends service life. They are cost-effective for industries needing reliable performance. Their robust design ensures consistent operation. This minimizes downtime and repair costs.

Applications in Various Industries

Chemical Processing

In chemical plants, these valves manage reactive chemicals. Their corrosion-resistant linings ensure safety. They maintain operational efficiency. They are used in processes like acid production or polymer synthesis. Precision is vital in these applications. The valves deliver accurate control. They prevent leaks and ensure smooth operations.

Oil and Gas

The oil and gas industry faces harsh environments. These include exploration, extraction, and refining. With corrosion-resistant linings, they handle crude oil, natural gas, or drilling additives. They ensure reliable performance. This is critical for safety and efficiency.

Water Treatment

Water treatment plants need dependable equipment. These valves are key in chemical dosing or pH adjustment. They handle corrosive agents like chlorine or sulfuric acid. Their precise flow control ensures consistent water quality. They also minimize wear from harsh chemicals. This enhances equipment longevity. It supports effective water purification.

Lined globe control valves combine engineering and high-quality materials. They are essential for industries needing precision and resilience. Their versatility makes them a top choice. They meet diverse operational demands.

Factors to Consider When Choosing a Valve

Media Compatibility

Choosing a valve requires checking its compatibility with the process media. The internal lining, often PTFE, resists corrosion. It protects against chemical damage. This makes them suitable for acids, alkalis, or solvents. The lining material must match the media’s chemical properties. This prevents wear. It ensures long-term reliability.

Globe valves are torque-seated. They handle on-off and throttling tasks. Their precise flow control is vital where specific rates matter. The lining reduces wear from abrasive materials. This boosts performance in tough settings. Proper material selection enhances valve efficiency. It ensures safe and consistent operation.

Temperature and Pressure Needs

Operating temperature and pressure are crucial. Valves must withstand extreme conditions. They should maintain structure and function. The lining material must remain effective under thermal and mechanical stress. This ensures reliable performance.

Globe valves come in Class 150-1500 configurations. This range suits various industrial needs. Matching the valve’s pressure rating to the system is key. This prevents failures or safety risks. Proper selection ensures operational stability. It supports long-term durability.

Maintenance and Costs

Maintenance and operational costs are important. These valves are durable due to strong builds and linings. They require less frequent repairs. This lowers costs over time. They are cost-effective for reliable flow control.

Their design allows easy disassembly and cleaning. This simplifies maintenance. These improve efficiency. They reduce downtime during servicing. This enhances overall productivity. It minimizes operational disruptions.

Miwival’s Role in Valve Technology

Advanced Corrosion Resistance

Miwival leads in lined globe control valve technology. We focus on superior corrosion resistance. Our valve products use high-quality linings like PTFE. These protect against chemical damage. This suits industries like chemical processing, oil and gas, and water treatment.

Miwival’s valves last longer. They maintain consistent performance. This reliability makes them ideal for harsh environments. Standard valves often fail early in such conditions. Miwival’s solutions ensure durability. They support efficient operations.

Reliable Sealing for Efficiency

Sealing is critical for control valves. It impacts efficiency and safety. Miwival’s valves offer excellent sealing. They minimize leaks, even under high pressure. The seat and gate work together to stop fluid flow. Miwival optimizes this with precise engineering. This achieves tight seals. It boosts system efficiency.

Industry Impact

Miwival’s contributions extend beyond products. We set benchmarks for valve technology. Our focus on corrosion resistance and sealing reliability influences industry practices. We provide solutions that reduce costs and improve outcomes. This makes us a leader in flow control.

Our valves are used in diverse applications. From chemical plants to oil rigs, we deliver results. Our designs adapt to specific needs. This ensures optimal performance. Miwival’s reputation grows with each innovation. We remain a trusted partner for industries worldwide.

FAQ

Q: What makes lined globe control valves effective for improving process efficiency?

A: Lined globe control valves boost efficiency through precise flow regulation and corrosion resistance. Their internal lining, often PTFE, protects against chemical damage, ensuring reliable performance in harsh environments. This reduces downtime and maintenance. The valve’s design allows accurate flow adjustments, optimizing processes like chemical dosing or fluid management.

Q: How does the corrosion resistance of these valves contribute to efficiency?

A: The corrosion-resistant lining shields the valve body from aggressive substances like acids or solvents. This prevents structural damage and extends service life. By minimizing wear, the valves maintain consistent performance, reducing the need for repairs or replacements. This ensures uninterrupted processes and lowers operational costs.