Purpose of Flow Control in Gate Valve Applications

Gate valves play an essential role in managing material flow – whether liquids, gases, or granular solids – across industrial systems. Their ability to maintain exact flow levels directly impacts performance. This precision boosts operational efficiency while preventing equipment strain and safety risks.

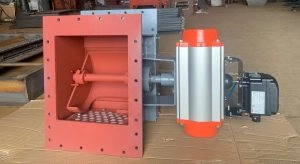

Flow Control Gate Valve Specifications

Key Features of Flow Control Gate Valves

Flow control gate valves manage the movement of materials, particularly bulk items like cement, lime, gypsum, and fly ash. They are installed at silo (bin) outlets to adjust material flow. Their structure ensures accurate control of flow rates. This promotes steady and effective industrial operations. These valves feature pneumatic rotary actuators and positioners. These components provide precise flow regulation with consistent outcomes. The pneumatic rotary actuator, paired with a positioner (feedback unit), operates the flow control gates. Their ability to maintain steady flow rates is vital for industries needing exact material handling.

Materials Used in Flow Control Gate Valves

The materials for flow control gate valves are selected for their strength and suitability with the handled media. Common choices include carbon steel and stainless steel. These materials resist corrosion and offer durability. For abrasive or corrosive substances, special coatings or linings may be added. This improves valve performance and lifespan. Using carbon steel, stainless steel, or other primary materials suits various media. These selections ensure valves endure high pressures and temperatures while staying reliable.

Design Considerations for Optimal Performance

The design of a flow control gate valve is crucial for its success. A tight seal between the valve seat and gate prevents leaks. It also enhances sealing efficiency. The sealing surface is often welded with metal to boost wear resistance. Other factors include low fluid resistance, ease of use, and maintenance needs. Adaptability to different mounting positions is also considered. Innovative features, like anti-cavitation elements, increase reliability. A rotating, dynamic Q-trim attenuator reduces cavitation and noise. These factors ensure the valve performs well in varied industrial settings.

Usage Areas of Flow Control Gate Valves

1. Water Treatment Systems

Flow control gate valves are essential in water treatment. They manage water distribution across treatment stages. Their ability to handle changing pressures ensures precise flow control. This leads to efficient processing. Their sturdy design makes them ideal for sediment-heavy water.

2. Oil and Gas Industries

These valves are widely used in oil and gas pipelines. They are key for controlling fluid transport. Mainline gate valves must have a full-bore or through-conduit design. This allows smooth passage of cleaning or monitoring tools like scrapers or pigs. Their ability to fully stop or allow fluid flow ensures safety during maintenance or emergencies.

3. Power Generation Plants

In power plants, these valves control steam flows for turbine operation. They handle high-pressure steam without losing performance. This makes them a top choice for such applications. They serve industries like oil and gas, chemical, petrochemical, and power plants.

4. Chemical Processing Industries

Chemical processing requires precise handling of chemicals under varying conditions. Bellows-sealed gate valves suit pipelines in petroleum, chemical, pharmaceutical, fertilizer, and power industries. Flow control gate valves provide excellent sealing. This prevents leaks and ensures safe material transfer.

Benefits of Using Flow Control Gate Valves

1. Enhancing System Efficiency Through Precise Regulation

Flow control gate valves ensure smooth industrial operations. They provide accurate material flow control. Installed at silo (bin) outlets, they manage bulk goods like cement, lime, gypsum, and fly ash. Consistent flow rates reduce process disruptions. This boosts system efficiency. Equipped with pneumatic rotary actuators and positioners, they offer high precision and repeatable results. These features are crucial for industries needing careful handling.

2. Reducing Energy Consumption with Effective Flow Management

These valves optimize material flow, cutting energy use in operations. Their design minimizes fluid resistance and ensures tight sealing. This reduces energy needed for pumping or moving materials. The sealing surface, welded with metal, increases wear resistance. This saves costs and supports eco-friendly goals by lowering environmental impact.

3. Prolonging System Lifespan by Minimizing Wear and Tear

Flow control gate valves are built for durability. They use strong materials like carbon steel and stainless steel. These withstand tough conditions. They handle abrasive or corrosive substances without rapid wear. This protects connected equipment, extending system lifespan. It also lowers maintenance costs and downtime.

Miwival’s Flow Control Gate Valve Advantages

1. High Precision in Regulation for Accurate Flow Management

Miwival’s flow control gate valves excel in precise flow regulation. Our globe control valves offer top performance and reliability across applications. These valves ensure consistent material handling, even under varying demands.

2. Exceptional Stability Under Various Operating Conditions

Miwival valves perform reliably in diverse settings, from chemical plants to power facilities. Their modular design allows customization for specific needs. The system includes valve body, sealing, trim, seat, stem seal, actuator, and positioner. This provides a tailored control solution for your process.

3. Superior Wear Resistance for Long-Lasting Performance

Miwival’s valves boast outstanding wear resistance. Premium materials and cutting-edge designs deliver long-lasting performance. They hold up reliably under intense pressure. The trim caters to precise flow requirements. This boosts efficiency while maintaining consistent operation and safety. Simple upkeep stands out as a major perk. Their clever clamp-seat mechanism enables fast servicing. No specialized tools are needed for routine maintenance.

FAQ

Q: What is the main purpose of flow control in gate valve applications?

A: Flow control in gate valve applications regulates the movement of materials, such as liquids, gases, or bulk solids, to ensure precise flow rates. This maintains efficiency, safety, and consistency in industrial processes like water treatment, oil and gas transport, power generation, and chemical processing.

Q: How do gate valves achieve effective flow control?

A: Gate valves achieve flow control through a gate mechanism that adjusts the flow path. Equipped with pneumatic rotary actuators and positioners, they provide accurate regulation. Their design ensures tight sealing and minimal fluid resistance, enabling precise and consistent flow management.

Q: Why is precise flow control important in industrial systems?

A: Reliable flow control prevents process disruption, optimizes system performance, and conserves energy. It facilitates secure handling of material under varied pressures and temperatures, a requirement in power plants, pipelines, and chemical processing.