How Segment Ball Valves Simplify Fluid Control in Pulp Mills

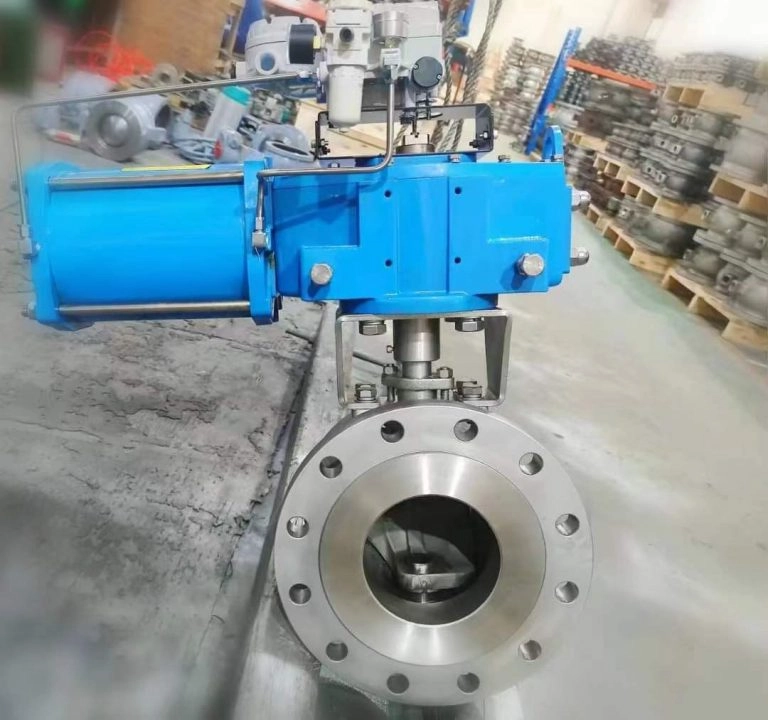

Handling fluids is super important in industries, especially in pulp mills. You’ve got to manage liquids and gases just right to keep things running smoothly and make high-quality products. Segment ball valves from Miwival are a solid choice for this job. They’re tough and reliable. This article looks at what makes these valves awesome, why they’re a big deal, and how they help in pulp mills.

3 Key Takeaways

- Segment ball valves are a must for spot-on fluid control in industrial work.

- They’re durable, save money, and stand up to rough conditions.

- Their design makes controlling flow easy, which is huge for pulp mill tasks.

What Are Segment Ball Valves?

Segment ball valves are smart tools that control fluid flow with serious precision. They’ve got a V-shaped piece inside the valve body. This lets you tweak flow rates like a pro.

What Makes Segment Ball Valves Special

These valves are built to last and work like a charm. Here’s what stands out:

- V-Port Design: The V-shaped opening lets you dial in fluid flow perfectly. It’s awesome for tasks that need careful tweaks.

- High Cv Value: These valves have a high flow coefficient (Cv). That means fluids zip through easily, even with shifting pressures.

- Small Size: Their compact build fits great in tight spots.

- Tough Materials: Made from things like stainless steel or corrosion-resistant alloys, they can tackle harsh chemicals and hot temperatures without flinching.

Why Fluid Control Is a Big Deal in Pulp Mills

Pulp mills deal with tricky processes. You’re moving water, chemicals, and pulp slurry around. Nailing fluid control keeps everything steady. It cuts down on waste and ensures your products are top-notch. Segment ball valves are champs in these tough settings. They handle weird flow changes and stay rock-solid.

Why Segment Ball Valves Are Awesome

Using segment ball valves in pulp mills comes with some cool benefits. They make things more efficient and keep costs low.

Spot-On Flow Control

Segment ball valves are fantastic at managing flow, thanks to their V-port design. Operators can adjust fluid movement just right. This keeps processes smooth and steady. They also stop problems like overflows or low flow, which can mess up production.

Built to Handle Tough Stuff

Pulp mills are rough on gear. You’ve got gritty materials, harsh chemicals, and crazy heat. Segment ball valves are made from super tough materials. They resist wear and corrosion, so they keep going strong for ages. This means less downtime for fixes or swaps.

Saving Cash and Hassle

These valves are sturdy, so you don’t need to mess with them much. They handle tough conditions, meaning you replace them less often. That saves money over time. Plus, their small size makes setting them up and maintaining them a snap. This keeps costs down.

By using segment ball valves, pulp mills can run better and spend less on keeping gear in shape.

Where Segment Ball Valves Rock in Pulp Mills

Their Role in Pulp Production

- Managing Chemical Processing

Turning raw materials into pulp relies heavily on chemical processing. Segment ball valves let you control chemical flows with precision for the chemical solution. This is key for getting the right mix and reactions. Their V-port design makes it easy to adjust flows accurately. This keeps the pulping process consistent and reduces waste, making chemical use more efficient.

These valves are pros at handling tough chemicals used in stuff like bleaching or delignification. Made from corrosion-resistant materials like stainless steel, they stay tough in harsh chemical settings. They also deal with high heat and pressure like it’s no big deal, making them perfect for heavy-duty chemical tasks in pulp production.

- Controlling Water and Steam Systems

Water and steam are super important for pulp mill jobs like washing, cooking, and drying. Segment ball valves help manage their flow. They keep things running smoothly across these steps. Their high Cv value lets fluids move efficiently, saving energy while keeping flows steady.

Their small size is great for cramped spaces. They give you precise control over water and steam, which boosts process stability and cuts downtime. Using these valves helps pulp mills use resources smarter and work more efficiently.

- Tackling Wastewater Treatment

Wastewater treatment is a huge part of pulp mills. It keeps you in line with environmental rules and protects nearby ecosystems. Segment ball valves are a go-to here. They handle changing flow conditions and all sorts of fluids with ease.

Their design lets them manage slurries with solid bits without clogging up. Their tough build stops wear, so they stay reliable in rough conditions. Plus, they’re easy to maintain, which cuts downtime and costs in wastewater treatment setups.

Technical Stuff About Segment Ball Valves

Design and Build Features

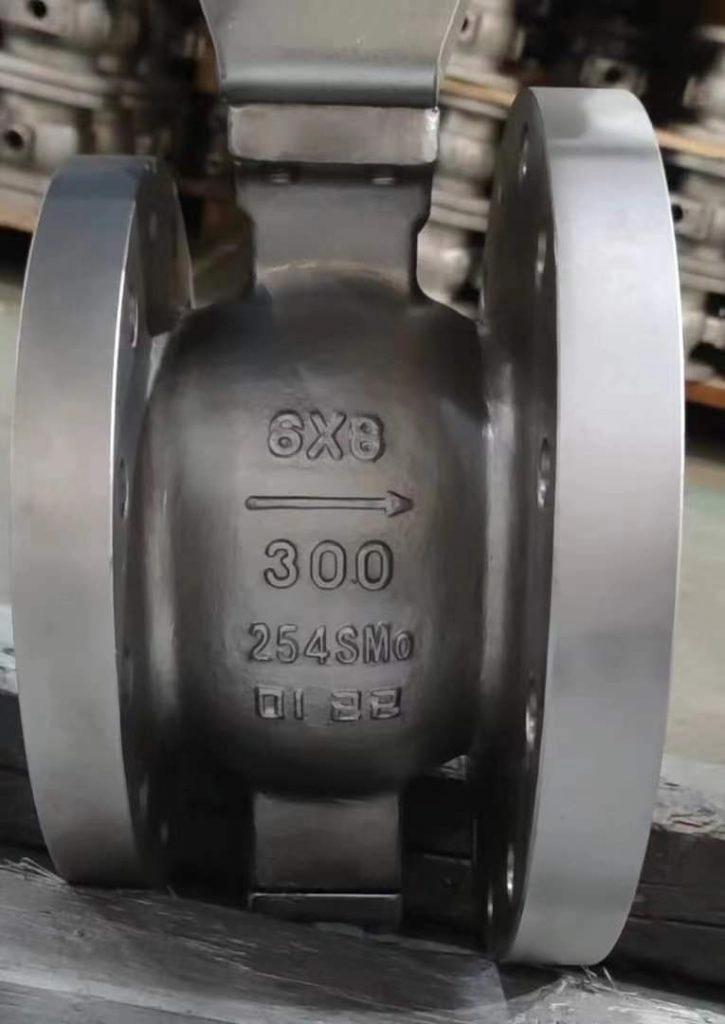

- Materials That Last

Segment ball valves are made from top-notch materials to handle industrial challenges. Think stainless steel, duplex steel, or other corrosion-resistant alloys. These keep valves going strong against gritty or corrosive stuff. They also hold up under extreme heat and high pressure.

Picking the right materials is key for matching specific pulp mill needs. For example, valves in chemical processing need to fight off corrosion. Those handling steam must stay stable in high heat.

- Why the Segment Design Stands Out

The segment design is what makes these valves unique. The V-shaped port gives you precise control over flow rates. It keeps things smooth and linear between the valve’s position and the flow. This makes adjustments spot-on across all sorts of conditions.

The design also cuts down on turbulence inside the valve. This reduces wear on parts and makes the valve last longer. It’s super helpful for handling gritty slurries or fast-moving fluids in pulp mills.

- Handling All Kinds of Fluids and Pressures

Segment ball valves can tackle all sorts of fluids—slurries with solids, gases, or steam. Their flexibility makes them great for tons of pulp mill tasks, from chemical processing to wastewater management.

They work great under different pressures without dropping the ball. Their ability to keep flow control steady across pressure ranges boosts stability and saves energy.

How Segment Ball Valves Compare to Other Valves

Segment Ball Valves vs. Traditional Ball Valves

Segment ball valves from Miwival and traditional ball valves both handle fluid flow, but they’re different beasts. Traditional ball valves use a spherical closure for simple on/off control. They’re not great for fine-tuning flow.

Segment ball valves, with their V-shaped port, let you adjust flow with precision. This makes them perfect for tricky pulp mill processes where accuracy matters.

Why They Outshine Gate and Globe Valves

Segment ball valves have some clear wins over gate and globe valves, making them a better pick for pulp mills:

- Smaller Footprint: They take up less room than gate or globe valves, so they’re easier to fit in tight spots.

- Better Flow Control: The V-port design gives smoother control than the linear setups in gate or globe valves.

- Tougher Build: Made from strong materials, they resist wear and corrosion better than gate or globe valves.

- Less Maintenance: Their simple design means less upkeep and reliable performance over time.

By tapping into these benefits, pulp mills can make their fluid control systems more efficient and cost-effective across production stages.

FAQ

Q: How do segment ball valves differ from regular ball valves?

A: Regular ball valves are great for on/off control but not for fine-tuning flow. Segment ball valves have a V-shaped port that lets you adjust flow rates with precision, making them perfect for complex tasks in pulp mills.

Q: What makes the V-port design so special?

A: The V-port design gives you spot-on control over fluid flow. It creates a smooth, linear connection between the valve’s position and the flow rate, so you can tweak things exactly how you need them.

Q: Why are segment ball valves good for harsh conditions in pulp mills?

A: They’re made from tough materials like stainless steel or corrosion-resistant alloys. These stand up to abrasive stuff, harsh chemicals, and high heat, so the valves last longer and need fewer repairs.