Choosing a Segmented Ball Valve vs. Standard Ball Valve: Key Differences

Dear business partners, if you’re knee-deep in industrial flow control decisions, picking the right valve can feel like navigating a maze. We Miwival team have been around valves long enough to know that one wrong choice, and you’re dealing with leaks, inefficiencies, or worse—downtime that costs a fortune. Today, we’re diving into segmented ball valves versus standard ball valves. What’s the big deal? Well, these two might look similar at first glance, but their differences can make or break your operation. We’ll break it down step by step, with real-world examples from industries like pulp and paper or chemical processing. By the end, you’ll have a clearer picture of which one fits your needs. Let’s get into it.

Understanding the Basics of Ball Valves

Ball valves, in general, are those reliable workhorses in pipelines. They use a spherical ball to control flow—turn it a quarter, and you’re open or shut. Simple, right? But not all ball valves are created equal. Standard ones are everywhere, from home plumbing to big oil rigs. Segmented ball valves? They’re the specialized cousins, built for trickier jobs. We once saw a standard ball valve fail spectacularly in a slurry line because it couldn’t handle the buildup—lesson learned the hard way.

What is a Standard Ball Valve?

A standard ball valve is your go-to for straightforward on/off control. Picture a full sphere with a hole drilled through it, rotating inside the valve body to let fluid pass or block it. They’re quick to operate—just 90 degrees—and seal tight when closed.

Pros?

They’re durable, low-maintenance, and handle high pressures well. Think stainless steel or brass bodies that laugh at corrosion. In applications like gas lines or water systems, they shine. For instance, in a municipal water treatment plant, standard ball valves might manage isolation points, shutting off sections for repairs without fuss.

But here’s the catch:

they’re not great for throttling. Try modulating flow, and you get uneven control, maybe even cavitation in liquids. Flow capacity is high when fully open, but partial positions? Not so precise. Sizes range from tiny 1/4-inch ports to massive 24-inch beasts, with pressure ratings up to 1,000 PSI or more, depending on the material.

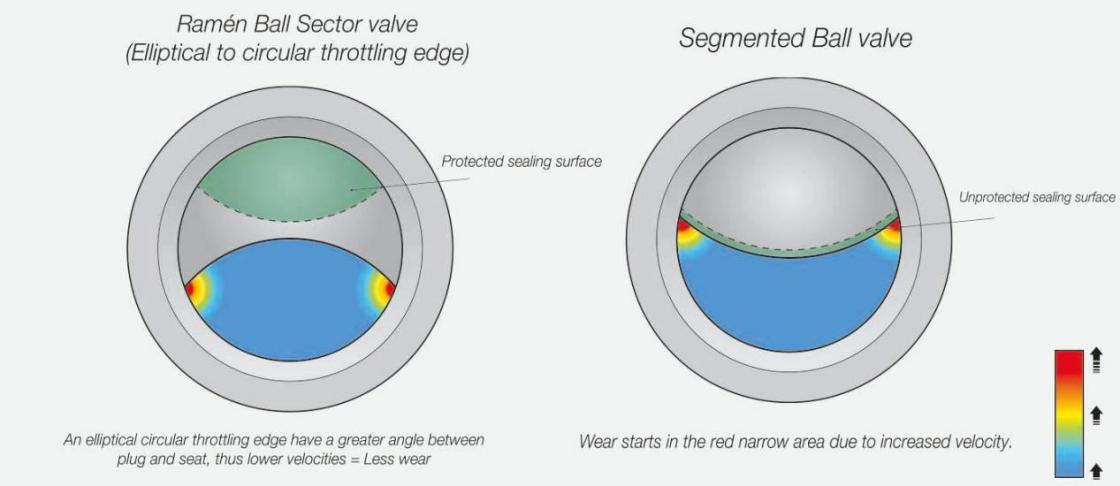

What is a Segmented Ball Valve?

Now, segmented ball valves step up the game. Instead of a full ball, they’ve got a contoured segment—like a slice of the ball with sharp edges. This design allows for better flow regulation, almost like a hybrid between a ball and a globe valve.

Key features

They include that self-cleaning action from the sharp edges, which shear through debris. They’re excellent for throttling, offering moderate to high precision. In the pulp and paper world, where slurries are thick and nasty, these valves prevent clogging. Imagine handling viscous pulp flows; a segmented valve keeps things moving without buildup.

They’re built tough too—often in stainless steel for abrasive environments. Flow control is smoother, with high capacity but less pressure drop than standards in modulated setups. Applications? Wastewater treatment, chemical processing, or oil and gas for fuels. One project we recall involved a chemical plant dosing aggressive fluids; the segmented valve’s precision cut waste by 15% compared to a standard one.

Key Differences: Segmented vs. Standard Ball Valves

Alright, let’s lay it out plain. The real juice is in how they stack up. Design-wise, standards are simple spheres for binary control; segmented have that notched segment for finesse.

Here’s a quick comparison table to visualize:

|

Feature |

Standard Ball Valve |

Segmented Ball Valve |

|

Design |

Full spherical ball with bore |

Contoured ball segment with sharp edges |

|

Flow Control |

Primarily on/off; poor throttling |

Excellent throttling; precise modulation |

|

Self-Cleaning |

No |

Yes, edges cut through solids |

|

Best For |

Clean fluids, gases, isolation |

High-viscosity slurries, debris-heavy flows |

|

Pressure Drop |

Low when fully open |

Minimal in throttling positions |

|

Applications |

Water, gas, general shutoff |

Pulp/paper, chemicals, wastewater |

|

Cost |

Generally lower |

Higher due to specialized design |

Flow precision

It is a biggie. Standards give you all-or-nothing; segmented offer linear control, ideal for metering. Resistance to clogging? Segmented wins hands down with that shearing action—think breaking down solids in wastewater, where standards might jam after a few cycles.

Durability?

Both are solid, but segmented handle abrasives better. In high-pressure spots, like 600 PSI in oil lines, standards might suffice for shutoff, but segmented thrive in varying flows. In addition, it should be noted that we have consulted with several engineers who strongly advocate the use of a segmented approach in batch processing, as it ensures precise dosing and helps prevent batch failure.

When Should You Choose a Segmented Ball Valve?

Go for segmented when control matters. If your fluid’s thick—like slurries in mining or pastes in food processing—these valves prevent backups. In a sugar refinery we visited, they used segmented valves for viscous syrup flows; standards would’ve clogged weekly, but these ran months without issues.

They’re perfect for throttling in chemicals or pharmaceuticals, where precise modulation avoids over-dosing. High-viscosity? Check. Solids? Double check. If you’re in pulp and paper, handling pulp with suspended bits, segmented’s self-cleaning keeps downtime low—maybe cutting maintenance by 20-30% based on what we’ve seen.

But don’t overlook the flip side;

They’re pricier upfront. Worth it if your process demands accuracy, though.

When to Stick with a Standard Ball Valve?

Standards are kings of simplicity. Need quick shutoff in clean gas or low-viscosity liquids? They’re your pick. In power plants for steam isolation, or cement factories for air lines, they do the job without bells and whistles.

Cost-effective for batch on/off ops, like in water treatment for tank isolation. No need for fancy if flow’s binary. We remember a small brewery using standards for beer lines—easy, cheap, and reliable. But push them into modulating duties, and you risk wear or leaks.

Factors to Consider Before Making Your Choice

Choosing boils down to your setup. Here’s what to weigh:

- Fluid Type:Clean and thin? Standard. Thick or debris-filled? Segmented.

- Control Needs:On/off only? Standard. Throttling required? Segmented for precision.

- Operating Conditions:High pressure or abrasives? Segmented’s robustness shines.

- Budget and Maintenance:Standards are cheaper to buy and fix; segmented pay off long-term in tough spots.

- Industry Standards:Check API or ASME ratings—segmented often meet harsher ones for slurries.

Also, think about actuators. Pneumatic ones pair well with both, but segmented might need finer controls. And always test in your system; simulations only go so far.

Introducing Miwival: Your Trusted Segmented Ball Valve Supplier

Speaking of reliable options, let’s talk about Miwival. They’re a solid player in the valve game, focusing on quality valves and automation for industries like pulp and paper, mining, chemicals, and more.

As a segmented ball valve supplier, Miwival stands out with their stock availability—two weeks delivery? That’s rare. They’ve got a full line, from control to isolation valves, all backed by total quality control from raw materials to finished products. Their mission? Valves and automation for a safer world, with a one-stop service vibe. If you’re hunting for segmented ball valves that handle slurries or precise flows, Miwival’s got the expertise, global reach in over 40 countries, and a team that’s all about customer-first. Worth checking if you need dependable gear without the wait.

Conclusion

Wrapping this up, choosing between a segmented ball valve and a standard ball valve isn’t rocket science—it’s about matching your needs. Standards keep it simple for shutoff; segmented bring the control for demanding flows. Factor in your fluid, application, and budget, and you’ll avoid headaches down the line. In the end, the right valve boosts efficiency and cuts costs—I’ve seen it turn operations around.

FAQs

What are the key differences when choosing a segmented ball valve over a standard ball valve?

The main ones are in flow control and handling. Segmented valves excel at throttling and self-cleaning in slurries, while standards are better for basic on/off in clean fluids. It’s all about your process demands.

Is a segmented ball valve always better than a standard ball valve?

Not always. If you just need isolation without modulation, a standard ball valve saves money and works fine. But for precision in viscous stuff, segmented wins—I’ve swapped them in and seen immediate improvements.

How do we know if we need a segmented ball valve for my application?

Look at your fluid: high-viscosity or solids? Yes, go segmented. For gas or water shutoff, standard might do. Test pressure drops too; segmented handle modulation without cavitation issues.

Can standard ball valves handle throttling like segmented ones?

They can try, but it’s rough—uneven flow and potential damage. Segmented are designed for it, with that contoured segment for smoother control. In chemicals, that’s a game-changer.

Where can we find a reliable supplier for segmented ball valves?

Check out folks like Miwival—they stock them and deliver fast. Always verify certifications, though; quality varies.