Enhancing System Performance with Innovative Globe Control Valves

Dear business partners, if you’re in the flow control game, you know how much a good valve can make or break a system. We Miwival team have been around industrial setups long enough to see how small tweaks in valve tech can lead to big wins in efficiency and reliability. Today, let’s dive into globe control valves – those unsung heroes that keep fluids moving just right. We’re talking about innovative designs that push the envelope on performance. Stick around; we’ll share some real-world stories and tips that might just spark an idea for your next project.

What Are Globe Control Valves Anyway?

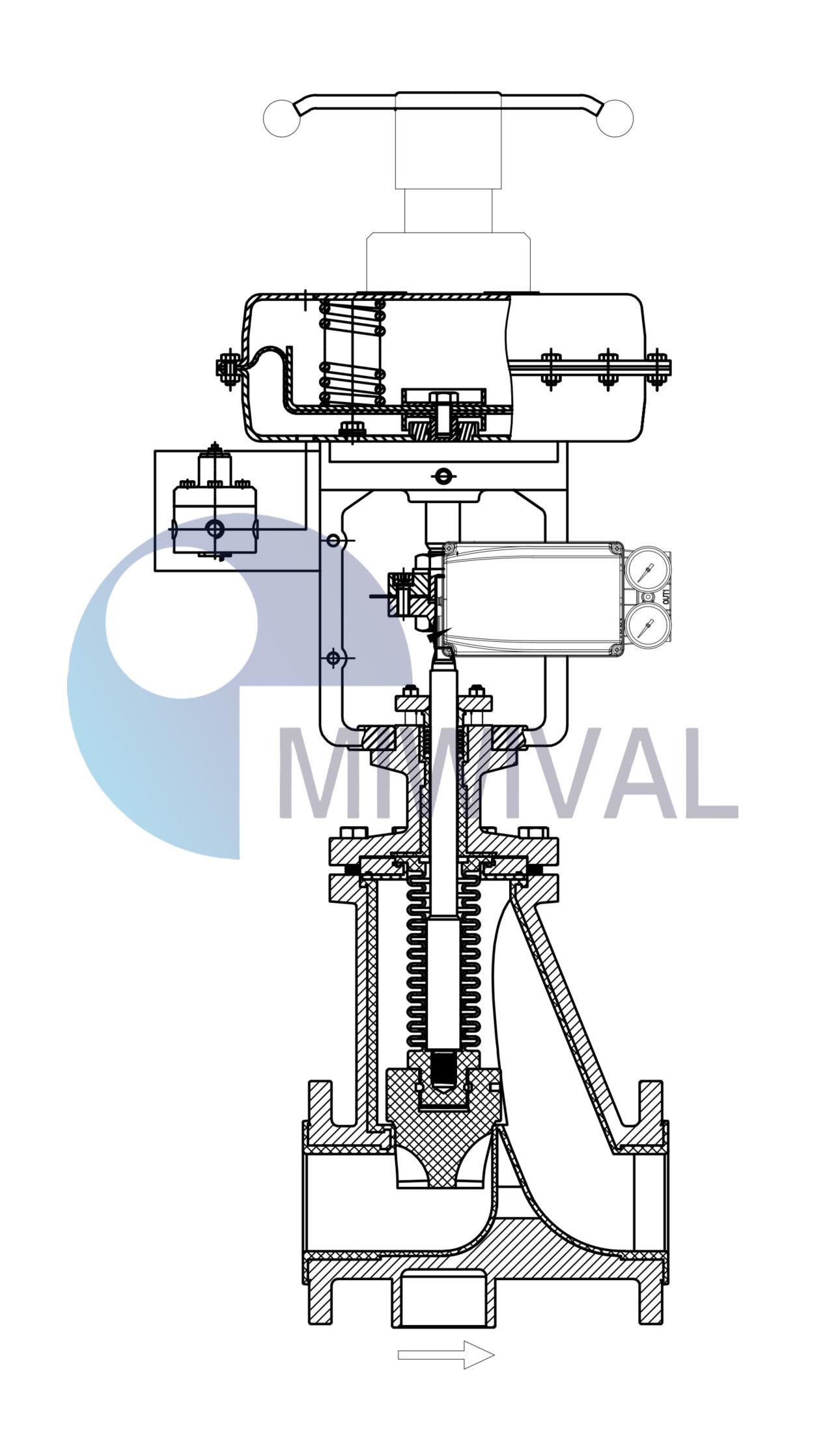

Globe control valves aren’t flashy, but they’re workhorses in controlling flow, pressure, and temperature in pipelines and processes. Picture this: a valve body shaped like a globe, with a movable plug or disk that sits inside, adjusting the flow path. The plug moves up and down, thanks to an actuator, to throttle the fluid – whether it’s water, steam, chemicals, or slurry.

These valves shine in applications needing precise control. Unlike ball valves that are more on-off, globe valves handle the in-between stuff beautifully. They create a tight seal and manage high pressure drops without much fuss. But here’s the thing – not all globe valves are created equal. Innovative ones come with bells and whistles like advanced sealing materials or smart actuators that respond in real-time.

We recall a chat with an engineer from a chemical plant; he strongly advocates globe valves for their throttling accuracy. “In our reactors,” he said, “a tiny miscalculation in flow can ruin a batch worth thousands.” That kind of precision it’s what sets them apart.

How Do They Work in Real Life?

At the heart of it, the valve’s stem connects to the actuator – could be pneumatic, electric, or hydraulic. When you signal it, the stem pushes or pulls the plug against the seat, changing the opening size. Flow characteristics? They can be linear, equal percentage, or quick-opening, depending on the trim design.

Take a steam system, for example. In power plants, globe valves regulate steam to turbines. If pressure spikes, the valve adjusts swiftly to avoid overloads. And with modern innovations, some even integrate IoT sensors for remote monitoring. It’s cool tech, but it also means fewer site visits and less downtime.

Standout Features of Innovative Globe Control Valves

What makes a globe control valve “innovative”? It’s all about the upgrades that tackle common pain points like wear, leaks, or energy loss. Let’s break it down.

Advanced Materials for Durability

Think corrosion-resistant alloys or self-adjusting seals. In harsh environments, like mining slurries, these prevent breakdowns. For instance, valves with fluoropolymer linings handle aggressive chemicals without corroding after just a few months.

Noise and Cavitation Control

Older valves can get noisy or cavitate – that’s when bubbles form and implode, chewing up internals. New designs use multi-stage trims to drop pressure gradually. We’ve seen noise levels cut by up to 20 dB in high-pressure drops, making plants quieter and safer.

Smart Actuation

Electric actuators with feedback loops? Game-changer. They allow for precise positioning, down to 0.1% accuracy. Plus, integration with PLC systems means automated adjustments based on real-time data.

Low Emission Designs

With regs getting tighter, low-fugitive emission packings are key. Some valves meet ISO 15848 standards, leaking less than 100 ppm of VOCs – crucial for chemical and oil industries.

A Quick Look at Trim Options

Trims are the guts of the valve – plug, seat, and cage. Here’s a simple table to compare common types:

|

Trim Type |

Best For |

Pros |

Cons |

|

Standard Plug |

General throttling |

Simple, cost-effective |

Prone to erosion in high-velocity flows |

|

Cage-Guided |

High-pressure drops |

Better stability, anti-cavitation |

Slightly higher cost |

|

Multi-Stage |

Noise reduction |

Quiets operation, extends life |

More complex assembly |

Pick based on your fluid and conditions. In pulp and paper mills, cage-guided trims handle fibrous slurries without clogging.

Boosting Performance Across Industries

Globe control valves aren’t one-trick ponies; they adapt to tons of sectors. From the docs we’ve pored over, they’re big in pulp and paper, mining, power, chemicals, and more. Let’s see how they enhance system performance in a few spots.

In pulp and paper, flow control is everything during digestion and bleaching. Innovative globe valves with pinch or butterfly hybrids manage slurry without leaks, cutting waste by 15-20% in some cases. One mill we know switched to these and saw their energy use drop because of better pressure regulation.

Mining? Slurries are brutal – abrasive and thick. Here, globe valves with robust seats isolate sections during dewatering. Imagine a pipeline rupture avoided because the valve throttled flow just in time. Reliability like that keeps operations humming 24/7.

For power and energy, steam applications demand precision. Globe valves in boiler feeds prevent flashing and cavitation, maintaining turbine efficiency. A study from a coal plant showed a 10% uptick in output after upgrading to innovative models with IoT integration.

Chemicals and wastewater? They deal with corrosives and varying flows. Low-emission globe valves ensure safety, while automated ones handle treatment phases seamlessly. In sugar processing, they control juice flow to avoid crystallization issues.

And we’ve tinkered with food and beverage setups too. Sanitary globe valves keep things hygienic, but that’s a whole other rabbit hole.

Real-World Wins: Numbers Don’t Lie

Let’s get specific. In a wastewater plant, installing globe control valves with equal percentage flow curves stabilized pH levels, reducing chemical dosing by 25%. Energy savings? Around 12% from smoother pump operations. Or take a cement factory – their kiln gas control improved combustion efficiency, slashing fuel costs by $50K a year.

These aren’t pie-in-the-sky figures; they’re from industry reports and chats with pros. The key? Matching the valve to the application’s demands.

Challenges and How Innovation Tackles Them

No valve is perfect. High pressure drops can lead to cavitation damage, eating away at seats over time. But innovative designs fight back with anti-cavitation trims – perforated cages that stage the drop. Noise? Attenuators built-in can dampen it.

Maintenance is another headache. Traditional valves might need full disassembly, but modular ones let you swap parts on the fly. And for remote sites, like oil fields, wireless monitoring means catching issues before they blow up.

Sometimes, though, folks overlook sizing. An oversized valve throttles poorly, leading to instability. Always calculate Cv values properly – it’s basic but often skipped in the rush.

Introducing Miwival as Your Globe Control Valve Supplier

If you’re hunting for reliable globe control valves, let us point you to Miwival. They’re a solid player in the valve world, focusing on quality, cost, delivery, and service. With stock ready to ship, they offer globe control valves tailored for industries like pulp and paper, mining, power, chemicals, and more. Their lineup includes innovative features like advanced actuators and corrosion-resistant materials, all backed by rigorous testing – from visual inspections to pressure trials. Miwival’s got a global reach, working with partners worldwide, and they’re all about one-stop solutions for valves and automation. Whether you need off-the-shelf or custom, they’ve got the expertise to keep your systems running smooth.

Conclusion

Wrapping this up, innovative globe control valves are more than just hardware – they’re key to enhancing system performance in tough industrial spots. From cutting noise and leaks to boosting efficiency with smart tech, they deliver real value. If your setup’s lagging, a fresh look at these valves could be the fix. And hey, with suppliers like Miwival in the mix, getting started is easier than ever.

FAQs

How do innovative globe control valves help in enhancing system performance?

They throttle flow precisely, reduce cavitation, and integrate with automation for better control. In a mining slurry line, for example, this means less wear and steady operations, cutting downtime.

What makes globe control valves innovative compared to older models?

Features like multi-stage trims for noise control or IoT sensors for real-time tweaks set them apart. It’s not just about lasting longer; it’s about smarter performance in high-pressure scenarios.

Can innovative globe control valves handle harsh environments like chemicals?

Absolutely. With corrosion-resistant linings and low-emission seals, they thrive in chemical plants, enhancing system performance by preventing leaks and ensuring safety.

Why choose Miwival for enhancing system performance with globe control valves?

Miwival stocks innovative options with quick delivery, focusing on quality and custom fits. Their valves have helped plants in power and wastewater see efficiency jumps of 10-20%.

Are there cost savings from using innovative globe control valves?

Yes, through lower maintenance and energy use. One power plant saved on fuel by optimizing steam flow, proving these valves pay off in the long run.