The Cost of Downtime: Why Investing in Reliable Flow Control Gates Saves Money in Mining and Cement

Picture this: It’s a busy shift at a cement plant, and everything’s humming along until a flow control gate jams up. Suddenly, production grinds to a halt. Workers scramble, managers sweat over lost hours, and the bottom line takes a hit. We’ve all heard stories like that in the mining and cement worlds, right? Downtime isn’t just an inconvenience—it’s a money pit. In this post, we’ll dig into why skimping on reliable flow control gates can cost you big time, and how smart investments pay off in the long run. Stick around; there are some eye-opening numbers and real-world tips ahead.

Picture this: It’s a busy shift at a cement plant, and everything’s humming along until a flow control gate jams up. Suddenly, production grinds to a halt. Workers scramble, managers sweat over lost hours, and the bottom line takes a hit. We’ve all heard stories like that in the mining and cement worlds, right? Downtime isn’t just an inconvenience—it’s a money pit. In this post, we’ll dig into why skimping on reliable flow control gates can cost you big time, and how smart investments pay off in the long run. Stick around; there are some eye-opening numbers and real-world tips ahead.

Understanding Downtime in Mining and Cement Operations

Downtime hits hard in heavy industries like mining and cement. These operations run on tight schedules, with massive equipment handling tons of material every hour. When something breaks, it’s not like flipping a switch back on. You’re talking lost production, idle crews, and sometimes even safety risks.

Let’s break it down. In mining, downtime often stems from equipment failures in slurry transport or material handling systems. Cement plants face similar headaches with silos and conveyors clogging up. According to industry reports, unplanned downtime can cost mining operations up to $100,000 per hour in lost revenue alone. Yeah, you read that right. And that’s not counting repair bills or overtime pay.

I remember chatting with a site manager at a quarry last year—he said a single gate failure once shut them down for half a day. They lost thousands in output, plus the hassle of rescheduling deliveries. It’s those hidden costs that sneak up on you: delayed shipments frustrating clients, or even penalties from contracts. In cement production, where margins are slim, every minute counts. The global cement industry churns out over 4 billion tons a year, but inefficiencies like this eat into profits.

Common Causes of Downtime

What sparks these shutdowns? Often, it’s faulty flow control at discharge points. Think about bulk materials like lime, gypsum, or fly ash piling up unevenly. Without precise control, gates wear out fast from abrasion or poor actuation.

- Mechanical Wear:Constant exposure to abrasive materials chews through cheap components.

- Actuator Failures:Pneumatic or electric systems without reliable positioners drift off course, leading to inconsistent flow.

- Clogging and Jams:Poor design lets materials bridge or rat-hole, stopping everything cold.

These issues aren’t rare. A study from the Mining Association showed that material handling accounts for 30% of unplanned stops. Cement folks deal with it too—dusty environments make seals fail quicker than you’d expect.

The Role of Flow Control Gates in Preventing Downtime

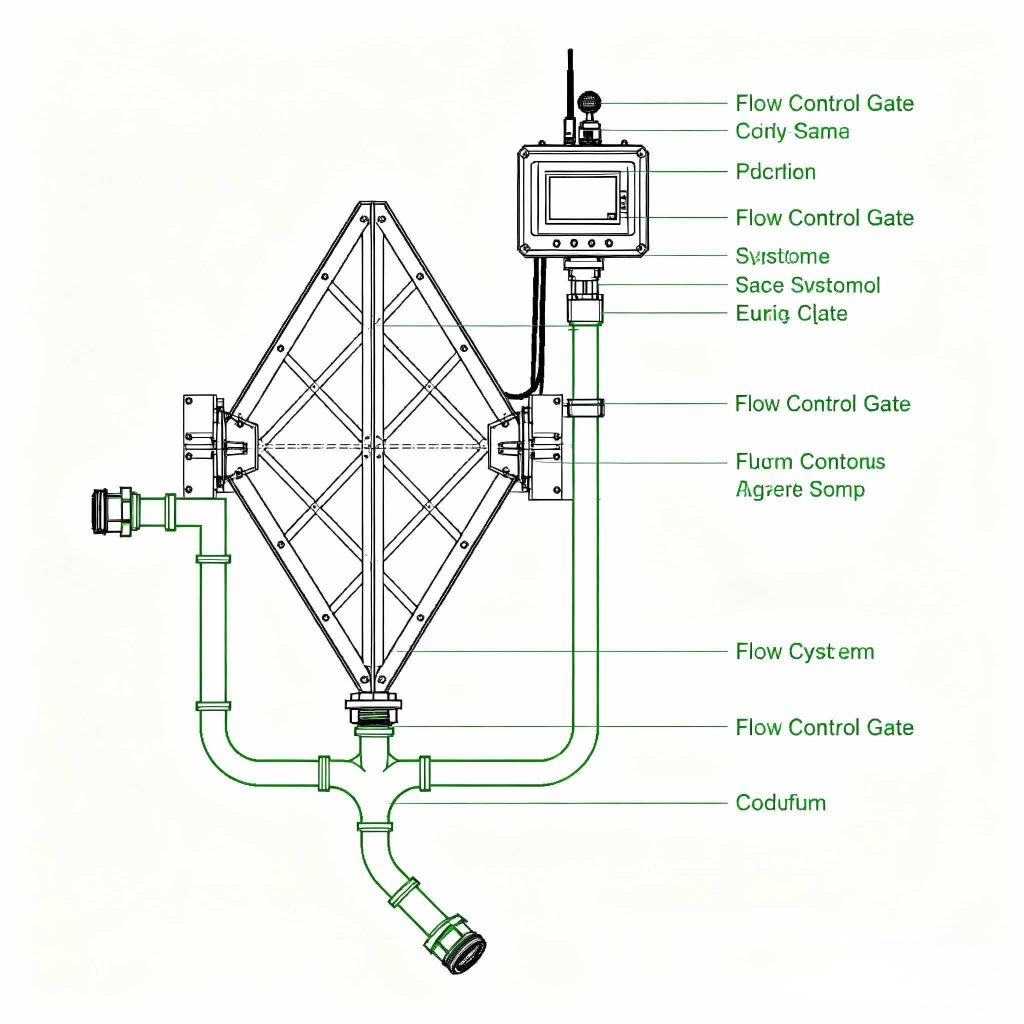

Flow control gates aren’t glamorous, but they’re the unsung heroes keeping things moving. Installed at silo discharges, they regulate the outflow of bulk goods, ensuring steady, controlled release. In mining, they handle ore slurries; in cement, they manage powders like cement or fly ash.

A solid gate uses fabricated steel bodies for durability, with options for pneumatic or electric actuators. Take pneumatic ones—they pair with positioners for 4-20mA feedback, hitting capacities up to 1000 tons per hour. That precision means no overflows or shortages, just smooth operations.

Why does this matter? Reliable gates cut variability. They deliver reproducible flow rates, which translates to fewer adjustments and less wear on downstream equipment like conveyors or mills. In a cement silo, for instance, a gate that opens partially on command prevents surges that could overload mixers.

Key Features That Make a Difference

Not all gates are created equal. Look for ones with high-accuracy actuators. Pneumatic rotary types with feedback units shine here—they adjust in real-time, adapting to material changes.

- Robust construction handles harsh conditions.

- Easy integration with control systems for automated ops.

- Low maintenance designs that last longer between services.

In mining pipelines, these gates isolate sections during maintenance, avoiding full shutdowns. Cement plants use them to fine-tune blends, boosting product quality without halting lines.

Calculating the Real Cost of Downtime

Let’s get crunchy with numbers. Say your mining operation processes 500 tons of ore per hour at $50 per ton profit. A four-hour downtime event? That’s $100,000 gone. But wait, add in labor: 20 workers at $40/hour idle, another $3,200. Repairs might run $5,000, and if it delays a shipment, tack on penalties.

In cement, it’s similar. A plant outputting 200 tons/hour at $10 profit per ton loses $8,000 in two hours. Factor in energy waste from idling kilns—easily another grand.

Here’s a quick table to visualize a typical scenario in a mid-sized cement facility:

|

Cost Category |

Estimated Loss per Hour |

Example for 4-Hour Downtime |

|

Lost Production Revenue |

$2,000 |

$8,000 |

|

Idle Labor |

$800 |

$3,200 |

|

Repair and Parts |

$500 (amortized) |

$2,000 |

|

Energy Waste |

$300 |

$1,200 |

|

Total |

$3,600 |

$14,400 |

Scary, huh? These figures come from averaged industry data, but plug in your own ops for a wake-up call. And that’s conservative—major incidents can balloon to millions if they trigger chain reactions, like equipment damage from backups.

One guy I know in the biz calculated his annual downtime losses at over $500K. Switched to better gates, and bam—cut it by half. It’s not rocket science; it’s basic math.

Benefits of Investing in Reliable Flow Control Gates

Spending upfront on quality gates feels painful, but the ROI is killer. First off, they slash maintenance downtime. With accurate control, wear evens out, extending life spans.

Safety improves too. Precise flow reduces spills or dust clouds that could lead to accidents. In mining, that’s huge—OSHA fines for hazards start at $15K.

Then there’s efficiency. Gates handling up to 1000 tons/hour keep throughput steady, optimizing energy use. Cement kilns run hotter and cleaner without flow interruptions.

- Long-Term Savings:Initial cost might be 20-30% higher, but payback comes in 6-12 months via reduced stops.

- Reproducibility:Consistent material discharge means better product uniformity, fewer rejects.

- Scalability:Sizes from B200-800 fit various setups, from small quarries to mega plants.

Don’t forget environmental perks. Better control cuts waste, helping meet regs without extra headaches. In an era of tight emissions rules, that’s a win.

Real-World Examples

Take a cement plant in Texas—they upgraded gates after repeated jams. Old ones lacked positioners, causing erratic flows. New pneumatic models with 4-20mA feedback dropped downtime by 40%. Annual savings? Around $200K.

In mining, an Australian gold operation faced slurry issues. Switched to fabricated steel gates; now they handle abrasive ores without flinching. Production up 15%, with fewer overhauls.

These aren’t hypotheticals. They’re from folks who’ve been there, grinding through the daily challenges.

Meet Miwival: Your Partner in Reliable Flow Control Solutions

If you’re hunting for dependable flow control gates, Miwival stands out as a go-to supplier. Based in China with a global footprint—they’ve built a rep for quality valves and automation. Started by valve pros with decades in the game, Miwival focuses on industries like mining and cement, offering gates that hit 1000 tons/hour capacities.

Their edge? Total quality control from raw materials to finished products, backed by ISO 9001. Think visual inspections, chemical analysis, pressure testing—the works. With a team led by experts like Forrest Shaoke Meng, they emphasize integrity, innovation, and customer-first service. Stock availability means quick deliveries, often in two weeks. Whether it’s pneumatic actuators with Siemens positioners or custom solutions, Miwival delivers reliability without the fluff.

Conclusion

Wrapping this up, downtime in mining and cement isn’t just a glitch—it’s a drain on your wallet and ops. Investing in reliable flow control gates flips the script, turning potential losses into steady gains. From cutting repair costs to boosting throughput, the math checks out. Next time a gate fails, remember: prevention beats cure every time. Ready to upgrade? It might just be the smartest move you make this year.

FAQs

What exactly is the cost of downtime in mining operations, and how do reliable flow control gates help reduce it?

The cost of downtime in mining can rack up fast—think $50,000 to $100,000 per hour in lost output, plus fixes and idle time. Reliable flow control gates minimize this by ensuring smooth material handling, preventing jams that lead to shutdowns. With precise actuation, they keep things flowing, saving money long-term.

Why should cement plants invest in reliable flow control gates to save money?

Cement production demands constant flow for efficiency. Unreliable gates cause clogs, spiking downtime costs like energy waste and delayed batches. Investing in gates with high-capacity designs (up to 1000 tons/hour) ensures reproducibility, slashing maintenance and boosting profits—often paying back in under a year.

How do flow control gates impact overall savings in harsh environments like mining and cement?

In dusty, abrasive settings, cheap gates fail quick, hiking repair bills. Reliable ones, built tough with feedback systems, endure longer, cutting unplanned stops. This saves money by maintaining steady ops, reducing waste, and avoiding safety fines—real savings that add up.

Are there specific features in flow control gates that directly address the cost of downtime?

Absolutely. Look for pneumatic actuators with 4-20mA positioners for accuracy, or fabricated steel bodies for durability. These features prevent inconsistencies that cause downtime, ensuring controlled flows of bulk materials and ultimately saving money through fewer interruptions.

Can small investments in flow control gates really make a big difference in saving money for mining and cement?

You bet. Even modest upgrades can trim downtime by 30-50%, based on industry cases. The key is choosing gates that match your needs—reliable ones turn small spends into big savings by keeping production humming without constant tweaks.