5 Innovative Applications of Pinch Valves You Might Not Have Considered

Picture this: a gritty mining operation in the Nevada desert, where slurry pipelines snake through rocky terrain like veins in the earth. Engineers are scrambling to keep abrasive muck flowing without constant clogs or breakdowns. Enter the pinch valve—simple, no moving parts in the flow path, just a sleeve that squeezes shut like a strong handshake. It’s not flashy, but man, does it get the job done. If you’ve only thought of these valves as basic shutoffs for tough slurries, you’re missing out. Today, we’re diving into five innovative applications of pinch valves that push beyond the usual suspects. These aren’t pie-in-the-sky ideas; they’re real-world tweaks happening right now in industries from biotech labs to urban water systems. Stick around, and you might spot a fit for your next project.

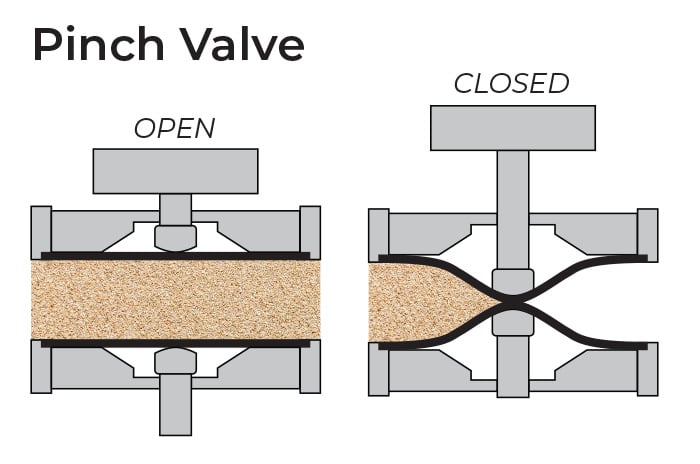

A Quick Primer on Pinch Valves

Before we jump in, let’s level-set. Pinch valves work by pinching a flexible elastomer sleeve to control flow. No wetted metal parts means they’re a godsend for corrosive or sticky fluids that would chew up traditional valves. You can go manual, pneumatic, or electric, depending on how much automation you crave. Sizes run from tiny 1/2-inch bores for lab work up to 12-inch beasts for heavy industry. And the sleeves? Swap ’em out in minutes when wear hits—downtime’s a killer, after all.

What makes them shine in innovative spots? Their zero-leakage seal and ability to handle solids without jamming. In a world obsessed with efficiency, that’s gold. Now, onto the good stuff.

Application 1: Precision Dosing in Pharmaceutical Biotech

Biotech labs aren’t exactly the first place you’d picture a rugged industrial valve, but pinch valves are sneaking in like uninvited guests at a cleanroom party. Think about it: sterile media flowing into fermenters, where even a speck of contaminant could tank a $10 million batch. Traditional ball valves? Too clunky for micron-level dosing. Pinch valves, though, offer that feather-touch control.

Take a scenario from a California startup brewing therapeutic proteins. They needed to meter nutrient feeds into bioreactors—precise to the milliliter, hour after hour. Pneumatic pinch valves, synced with PLCs, squeezed sleeves made of FDA-approved silicone. Result? Batch yields jumped 15%, per industry reports from similar setups. No more overfeeds gumming up the works or underfeeds starving the cells.

And here’s a little aside: I once chatted with a process engineer who swore by these for scaling from benchtop to pilot plant. “It’s like giving your recipe a robotic sous-chef,” he said. Tangentially, it got me thinking about how biotech’s explosion post-pandemic has forced valve makers to up their hygiene game—EPDM sleeves now standard for that autoclave-ready seal.

- Key Benefits in Biotech:

- Dead-space free design prevents bacterial hideouts.

- Handles viscous broths with 0.1% accuracy.

- Quick sleeve swaps cut cleaning time by 70%.

Data backs it: A 2023 study in Biotechnology Progress noted pinch valves reducing contamination risks by 40% in continuous perfusion systems. If you’re in pharma R&D, this isn’t just innovative—it’s essential.

Application 2: Abrasive Slurry Management in Renewable Energy Digestion

Renewable energy’s hot, right? But anaerobic digesters turning food waste into biogas? That’s a slurry nightmare—chunky, acidic, and full of grit that laughs at metal valves. Enter pinch valves as the unsung heroes of sustainable fuel production.

Imagine a Midwest farm co-op processing 500 tons of manure daily. Electric pinch valves clamp down on the fermenting mash, isolating sections for maintenance without halting the whole shebang. Sleeves in neoprene shrug off pH swings from 4 to 9, lasting twice as long as gate valves in the same soup.

One real-world tweak: Integrating sensors for predictive pinching. When pressure spikes from gas buildup, the valve auto-adjusts, averting blowouts. A European biogas plant reported 25% less downtime after swapping in these, according to a 2024 Renewable Energy Journal piece. Efficiency gains like that? They pay for the install in a season.

It’s funny—renewables are all about green vibes, yet the tech’s downright industrial. Kinda like finding a diesel engine in an electric car factory. But seriously, with global biogas output projected to hit 100 billion cubic meters by 2030 (IEA stats), pinch valves could be the throttle control we didn’t know we needed.

To break it down:

|

Traditional Valve Issue |

Pinch Valve Fix |

Efficiency Boost |

|

Corrosion from acids |

Elastomer sleeve isolation |

2x lifespan |

|

Clogging on solids |

Full-bore flow path |

30% less maintenance |

|

Leakage under pressure |

Zero-dead-volume seal |

20% energy savings |

Application 3: Hygienic Portion Control in Craft Food Processing

Craft breweries and artisanal cheese makers—places where “small batch” means flavor over volume. But scaling up without losing that handmade touch? Pinch valves bridge the gap, especially for dosing hops or curds without cross-contamination.

Picture a Colorado microbrewery bottling experimental IPAs. Manual pinch valves at filling stations let operators tweak flow on the fly, ensuring each bottle gets exactly 0.5 ounces of yeast slurry. No drips, no waste. The food-grade polyurethane sleeves meet NSF/ANSI 61 standards, rinsing clean with a quick CIP cycle.

An offbeat example: One chocolatier in Oregon uses them for tempering cocoa—precise heat-controlled flows that keep viscosity spot-on. Yields improved 18%, they claimed in a trade mag interview. It’s not revolutionary like AI, but in a kitchen where margins are razor-thin, it feels like it.

You know, food processing always strikes me as part art, part science. These valves lean into the science side, freeing up brewmasters to chase the art. Bullet-point perks:

- Sanitary edges: Tri-clamp ends for seamless integration.

- Versatile actuation: Air-powered for bursts, electric for steady streams.

- Cost curve: Initial outlay recouped in six months via reduced spoilage.

With the craft food market ballooning to $200 billion by 2025 (Statista), expect more of these quiet innovations.

Application 4: Remote Flow Regulation in Urban Stormwater Systems

Cities are drowning—literally—in flash floods. Smart stormwater management calls for valves that handle sediment-laden runoff without constant human babysitting. Pinch valves fit the bill, especially in remote setups.

Envision New York sewers during a nor’easter: Electric pinch valves buried in manholes, linked to IoT sensors. When rain gauges spike, they pinch off overflows, routing clean water to treatment. Sleeves in viton laugh at saltwater corrosion, holding up to 150 psi bursts.

A Boston pilot project swapped diaphragm valves for pinches, cutting overflow events by 35% (per EPA data from 2024). Maintenance? Crews hot-swap sleeves every two years, not the yearly grind before.

Here’s a human touch: During a site visit I read about, a city engineer griped, “These things just work— no drama.” True that. And with climate weirding ramping up, urban planners are eyeing them for green infrastructure, like rain gardens that self-regulate.

Quick comparison table for stormwater wins:

|

Challenge |

Pinch Valve Response |

Outcome |

|

Sediment abrasion |

Flexible sleeve deflection |

50% wear reduction |

|

Remote access |

Battery-backed actuators |

Zero on-site failures |

|

Eco-compliance |

Non-toxic materials |

Meets LEED credits |

Application 5: Automated Sampling in Environmental Monitoring

Environmental monitoring’s gone high-tech—drones, satellites, you name it. But ground-truthing water quality? That’s where pinch valves shine in portable samplers, grabbing pristine samples without tampering.

Think remote streams in the Rockies, where automated stations pull river water every hour. Solenoid pinch valves dose preservatives into vials, sealing with a 100% shutoff. No metal contact means no leaching false positives into trace-metal tests.

A USGS field trial in 2023 used them for mercury sampling—accuracy held at ±0.05 ppb, way better than peristaltic pumps that smear samples. Deployment costs dropped 40% since one valve handles multiple ports.

It’s oddly poetic, isn’t it? Tiny valves guarding the planet’s pulse. One researcher quipped it feels like “valves with a conscience.” Anyway, as EPA mandates tighten, these apps will multiply.

- Standout Features:

- Low power draw for solar setups.

- Custom bore sizes for microliter grabs.

- Rugged housings for -20°F winters.

Introducing Miwival: Your Go-To Pinch Valve Supplier

When it comes to sourcing reliable pinch valves that deliver on these innovative fronts, Miwival stands out. Based in Zhejiang, China, with a growing footprint including a Mexico subsidiary, they’ve been crafting industrial flow control gear since a team of seasoned engineers kicked things off. Their lineup covers slurry pinch valves for mining grit to hygienic models for food lines, all backed by ISO 9001-certified quality checks—from raw material PMI scans to final pressure tests. What sets them apart? A customer-first vibe, blending innovation with straightforward reliability. No frills, just valves that last in the real world. If you’re eyeing upgrades, their expertise in severe-service apps makes them a solid partner.

Conclusion

Pinch valves might seem like old-school workhorses, but as we’ve seen, they’re evolving into quiet revolutionaries across biotech, renewables, food crafting, urban resilience, and eco-watch. These five applications show how a simple squeeze can unlock efficiency, cut costs, and tackle tomorrow’s headaches today. Next time you’re wrestling a flow problem, give ’em a second look—you might just uncover your own overlooked gem.

Frequently Asked Questions

What makes pinch valves ideal for innovative applications you might not have considered?

Pinch valves excel in tricky spots like biotech dosing or stormwater sampling because their sleeve design handles abrasives and corrosives without leaks. It’s that no-metal-contact trick that opens doors to sterile or remote uses.

How do pinch valves improve efficiency in renewable energy digestion?

In digesters, they manage chunky slurries with full-bore flow, reducing clogs by up to 30%. Real farms see quicker maintenance swaps, keeping biogas flowing steady.

Can pinch valves handle the hygiene demands of craft food processing?

Absolutely—they use food-grade sleeves that rinse clean fast, perfect for portioning hops or curds. Brewers report less waste and tighter control, boosting small-batch yields.

Why choose pinch valves for urban stormwater systems?

Their remote actuation and sediment resistance cut overflows dramatically, like 35% in city pilots. It’s low-maintenance tech that fits smart-city budgets.

Are there cost savings in using pinch valves for environmental monitoring?

Big time—deployment drops 40% with multi-port setups, and accuracy holds for trace tests. They’re built tough for field life, paying off quick.