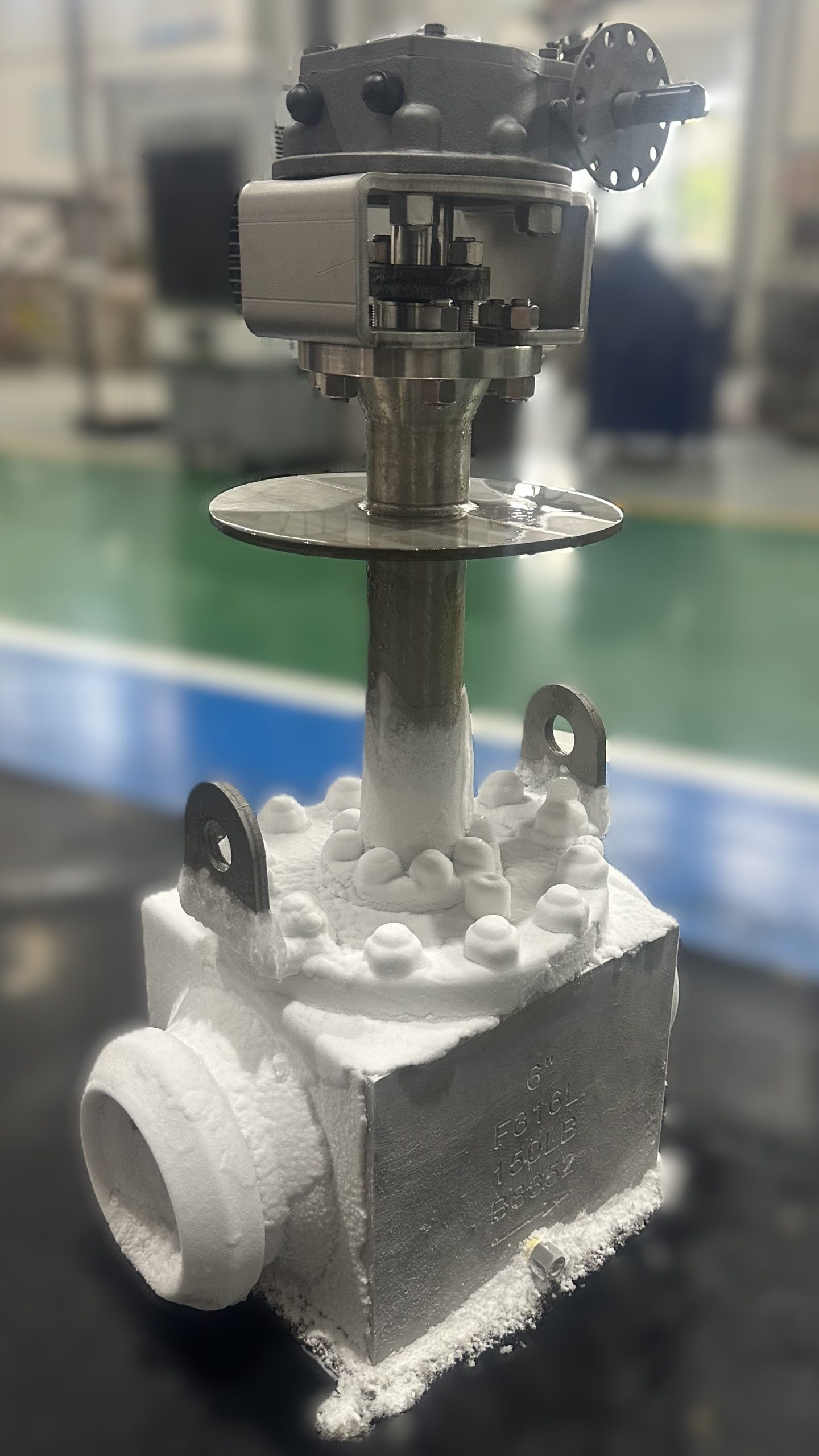

Top Entry Cryogenic ball valve for LNG

Suitable for request with low-temperature media and high sealing requirements, covering multiple fields such as energy, chemical industry, and aerospace.

Features

The core features of cryogenic ball valves are adaptability to low-temperature environments, reliable sealing performance, and a structure resistant to brittle fracture, while also ensuring ease of operation and adaptability to various working conditions.

Performance Characteristics:

1. High low-temperature toughness. Be made of cryogenically resistant materials (304L, 316L, etc.), eliminating the risk of brittle fracture even at -196℃ in deep cryogenic conditions.

2. Excellent sealing performance. Soft seals can achieve near-zero leakage at ANSI Class VI level, while hard seals are suitable for high-pressure and low-temperature scenarios.

3. Anti-icing design; the valve stem uses an extended structure with an insulation layer to prevent frost and ice formation on the valve stem due to the conduction of low-temperature media.

Structural Design Features:

1. Tight seal. The valve seat often uses an elastic compensation structure to offset material shrinkage at low temperatures, ensuring a tight seal.

2. Easy to operate. Optimized operating mechanism; uses a low-temperature-specific lubricant or a lubrication-free design to avoid jamming at low temperatures and reduce operating torque.

3. Fire safe design. The fire-resistant structural design replaces burnt soft seals, forming a temporary seal to prevent continuous leakage of the media and effectively prevent explosions or the spread of fire.

Application Compatibility Features:

1. Wide media compatibility, adaptable to cryogenic media such as LNG, liquid oxygen/nitrogen/hydrogen, with superior corrosion resistance compared to ordinary ball valves.

2. Flexible operating condition adaptation. PN10 ~ PN100, DN25 ~ DN600+, meeting the needs of various scenarios.

3. Convenient maintenance, the three-piece body and top entry design allows for online inspection of the valve ball and seat without the need for complete disassembly, reducing downtime.

APPLICATIONS

- Energy Industry: Storage, transportation, and refueling of LNG (liquefied natural gas), operating temperature -162℃. Flammable and volatile medium, requiring near-zero leakage.

- Chemical Industry: Preparation and transportation of cryogenic gases such as liquid oxygen/nitrogen/argon, -183℃ ~ -196℃. Some media have strong oxidizing or inert properties.

- Aerospace/Military Industry: Transportation and control of cryogenic propellants such as liquid hydrogen and liquid helium, -253℃. Materials must be resistant to cracking and the structure must be pressure-resistant.

- Cold Chain/Pharmaceutical Industry: Refrigerant circulation in cryogenic cold storage refrigeration systems and pharmaceutical freeze-drying equipment, -46℃ ~ -80℃.