An vent valve is used to remove trapped air (or other non-condensable gases) from pipelines or equipment, preventing air blockage and cavitation problems, and ensuring the stable operation of fluid systems.

Ⅰ. Structure

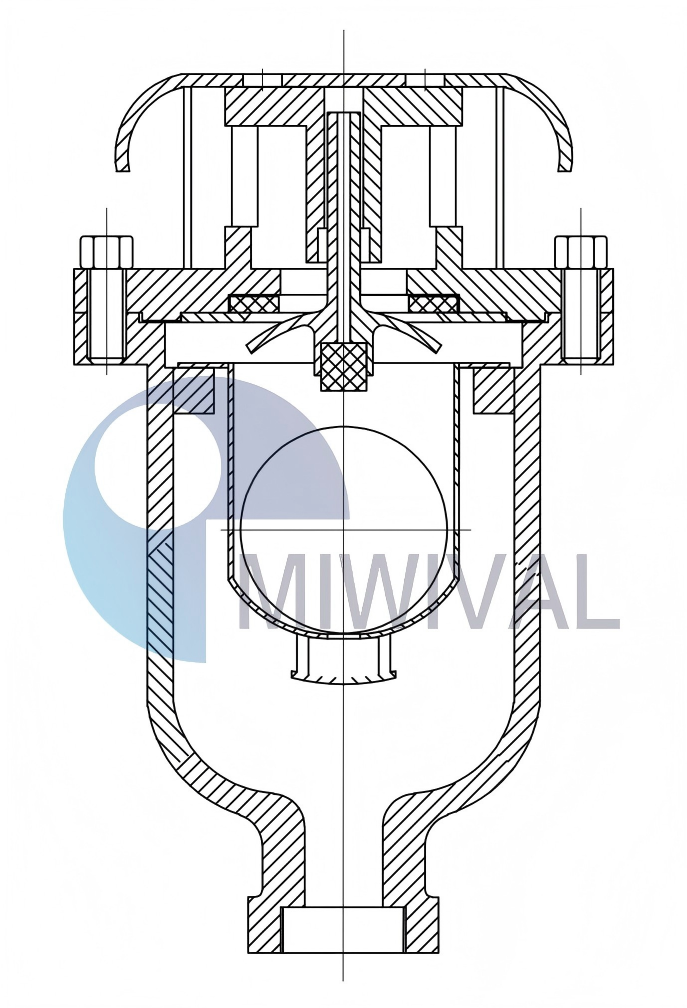

1. Valve Body: The overall structure is straight-through or angled, with internal inlet and outlet channels.

2. Float Ball: The core control component, including a float ball and connecting rod mechanism. The float ball rises and falls with the fluid level, controlling the opening and closing of the exhaust port.

3. Exhaust Port and Valve Disc: The top of the valve body is equipped with an exhaust port and avalve disc. The valve disc is linked to the connecting rod to achieve precise sealing.

4. Filter Screen: Installed at the media inlet to intercept impurities, preventing the float ball and valve disc from jamming, and ensuring reliable valve operation.

5. Manual Exhaust Port: Some models are equipped with a manual exhaust knob for manual air release during initial system filling or in case of malfunction.

Ⅱ. Working Principle

Its working process is divided into three stages, the core of which is the automatic opening and closing based on the float ball’s liquid level sensing:

1. Exhaust Stage: When the system is filled with water or started, the air in the pipeline accumulates at the vent valveinstallation location. At this time, the fluid level inside the valve is low, the float ball sinks, and the connecting rod drives the valve disc to open the exhaust port, allowing air to be discharged through the exhaust port.

2. Sealing Stage: After the air is completely discharged, the fluid fills the valve chamber, the float ball rises with the liquid level, and the connecting rod pushes the valve disc to press against the exhaust port, achieving sealing and preventing fluid leakage.

3. Secondary Exhaust Stage: If new air is generated during system operation (such as dissolved gas precipitation from the fluid, or gas generated by temperature changes), the air will accumulate in the valve again, causing the liquid level to drop, the float ball to sink, and the exhaust port to reopen for air release, repeating the cycle.

III. Features

1. Automatic Operation, No Supervision Required: The vent valvecan automatically open and close according to the air content inside the valve, without manual intervention, reducing operation and maintenance costs.

2. High Exhaust Efficiency: The composite vent valvecombines “large air discharge capacity” (rapid air discharge during system filling) and “micro-air discharge” (discharging dissolved gas during operation) functions, adapting to different stage requirements.

3. Protection of System Safety: Effectively eliminates air pockets in pipelines, preventing pump cavitation, pipeline vibration and noise, and extending equipment service life.

4. Convenient Installation: Small size and light weight, usually installed vertically at the highest point of the pipeline, with simple connection methods.

Ⅳ. Applications

1. Water Supply and Drainage Systems

Tap water transmission pipelines, high-rise building water supply systems, fire water pipe networks: Installed at the highest point of the pipeline to remove air during water filling, preventing air blockage from causing poor water flow and ensuring stable water supply pressure.

Sewage lifting pipelines in sewage treatment plants: Removes biogas and other gases released from sewage, preventing pipeline rupture.

2. HVAC and Refrigeration Systems

Central air conditioning water circulation pipelines, heating hot water pipelines: Removes air from the system, preventing air blockage from affecting the heat exchanger’s efficiency and preventing oxidation and corrosion of the inner wall of the pipeline.

Underfloor heating systems: Installed above the manifold, removing air from the pipeline to ensure even heat dissipation.

3. Industrial Fluid Systems

Chemical raw material conveying pipelines, hydraulic oil pipelines: Removes non-condensable gases from the pipeline, preventing cavitation damage to pumps and precision valves.

Condensate pipelines in steam systems: Removes air from the condensate, improving condensate recovery efficiency.

4. Agricultural Irrigation Systems

Agricultural irrigation pipe networks, drip irrigation systems: Removes air from the pipelines, preventing water flow interruption and ensuring even irrigation.