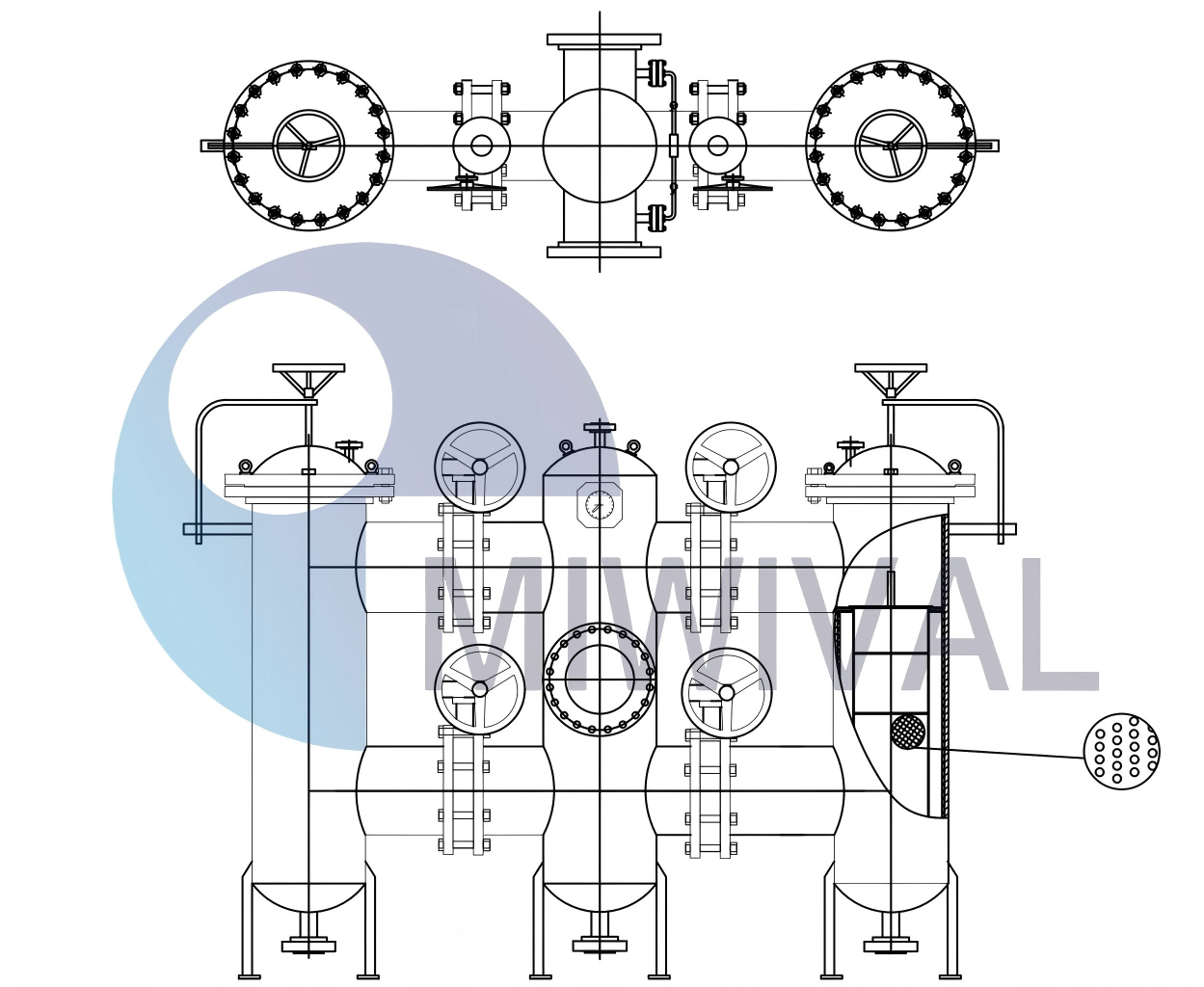

Ⅰ. Structure of Double Barrel Strainers

The double barrel strainers consist of two independent strainers connected in parallel. The structure includes the following parts:

1. Two Sets of Barrel Strainers: Two symmetrical strainers, each with a built-in filter screen. Bodymaterial can be cast iron, carbon steel, or stainless steel depending on the working conditions.

2. Switching Valves: The core control component, usually a ball valve, butterfly valve, or plug valve, used to control the flow direction, allowing for single-straineroperation, single-strainer standby, or simultaneous operation of both strainers.

3. Filter Screen: The core filtering element, with a precision range covering 10-1000 mesh, mostly made of stainless steel.

4. Drain Port and Vent Port: Each strainerhas a drain port at the bottom for cleaning out retained impurities; a vent port is located at the top to prevent air accumulation in the filtering chamber from affecting efficiency.

5. Differential Pressure Gauge/Transmitter: Monitors the pressure difference between the inlet and outlet of the filter screen. When the pressure difference reaches a set value, it indicates that the filter screen needs cleaning.

6. Sealing Components: Using PTFE, rubber, or metal seals, adapted to different temperatures and corrosive media.

Ⅱ. Working Principle

The core advantage of the double barrier strainers is uninterrupted filtration. The working process is divided into two modes:

1. Single-strainer Operation, Single-strainer Standby Mode

(1) The medium enters the working strainer, passes through the filter screen, and solid impurities are retained. The clean medium flows out to the downstream equipment; at this time, the standby strainer is in an unloaded state.

(2) When the pressure difference of the working strainer’s filter screen exceeds the limit, the switching valve is rotated to switch the medium flow to the standby strainer, and the original working strainer is immediately taken offline.

(3) After going offline, the drain port of the working strainer can be opened for drainage, or the filter screen can be removed for cleaning or replacement. The entire process does not require shutdown and does not affect the continuous operation of the pipeline system.

2. Two-strainer Parallel Operation Mode

The switching valve is opened, and the medium enters both strainers simultaneously for filtration, suitable for high-flow conditions, which can improve the overall filtration capacity.

III. Features

1. Uninterrupted Filtration: Online maintenance is achieved through the switching valve, solving the problem of single-strainerfilters requiring shutdown for cleaning, making it suitable for systems with high continuity requirements. 2. Strong Adaptability: Different precision filter screens can be selected according to requirements, accommodating both coarse and fine filtration; the double-barrel structure can handle larger flow rates with minimal pressure loss.

2. Flexible Maintenance: Offline cleaning and filter screen replacement are simple, requiring no disassembly of the main pipeline, reducing maintenance costs and downtime risks.

3. Wide Range of Applications: Suitable for liquid and gas media, and through material selection, it can withstand corrosive, high-temperature, and high-pressure environments.

Ⅳ. Application

Double-barrel filters are suitable for continuous production systems where downtime is not permitted. Typical scenarios include:

1. Hydraulic and Lubrication Systems

Filtration of lubricating oil/hydraulic oil in hydraulic stations, gearboxes, and steam turbines, intercepting impurities in the oil to protect precision components such as oil pumps, strainers, and bearings. It is a core protection device for industrial power systems.

2. Petrochemical Industry

Filtration of crude oil, refined oil, and chemical raw materials in pipelines, especially suitable for continuous production sections in refineries and chemical plants, avoiding production line interruptions due to downtime for filtration.

3. Power Industry

Filtration of boiler feedwater, circulating water, and cooling oil in thermal power plants and nuclear power plants, ensuring the continuous and stable operation of generator sets and steam turbines.

4. Food and Pharmaceutical Industry

Filtration of beverages, dairy products, and pharmaceutical raw materials. Using sanitary-grade stainless steel materials, it allows for online cleaning and meets food and pharmaceutical hygiene standards.

5. Metallurgy and Mining Industry

Filtration of smelting cooling water and ore slurry, capable of handling media with high impurity content, adapting to harsh working conditions, and ensuring continuous equipment operation.