A Buyer’s Guide to Selecting the Right Diaphragm Valve (Body Material, Diaphragm Type & More)

Ever stepped into a factory where the air carries that sharp tang of chemicals? You notice those smooth valves chugging away. They keep spills from happening. That’s the steady work of diaphragm valves. Now, if you’re deep in buying gear for a production line or just checking out choices for a fresh setup, grabbing the flashiest one isn’t the way. You need to fit the valve’s core parts—like body material and diaphragm type—to the hard facts of your job. This guide lays it out, plain and simple. No extra talk. We’ll hit the basics. Then we’ll dig into what keeps a valve running strong. Or not. Plus, we’ll toss in some straight-up advice from people who’ve dealt with it. When you’re done, you’ll spot a solid pick easier.

What Makes a Diaphragm Valve Tick?

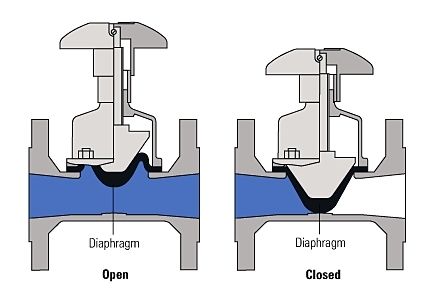

Think of a valve that seals firm without any parts rubbing the stream. That’s a diaphragm valve, boiled down. It relies on a bendy sheet—the diaphragm—to manage the flow. This sheet presses against a ridge or base with a pusher. Pretty basic, huh? But that easy setup delivers big in rough conditions.

The Inner Workings: A Quick Peek Under the Hood

Deep down, the valve breaks into a body, the diaphragm, a rod, and a cap. You twist the wheel. Then the rod shoves the pusher lower. It bends the diaphragm to stop the flow. Pull it back, and the liquid moves free. No slides or spheres to clog with muck or eat away from sour stuff. I talked to a fellow once. He ran a sewage cleanup operation. He loved these for their “install and ignore” feel. Less fixes mean more running time. Just like that.

So why dig into this? In fields like drug making or food handling, dirt is a real headache. The diaphragm blocks it off. If it gives out, the body stays shut. No drips creep into the system. Reports from factory checks show these cut repair visits by nearly a third in eating-away setups. That’s from long stretches of on-site notes.

Why Choose Diaphragm Over Globe or Ball Valves?

Ball valves cost little and snap shut fast. But they struggle with thick mixes. Globe valves? They throttle well. Yet they drip bad in pull-down lines. Diaphragm valves stand out where clean or cutoff counts. Weir styles drain on their own. That’s spot-on for gooey leftovers. And for grinding flows? The diaphragm catches the wear. It saves the body. Not too shabby for gear that seems lab-bound, right?

Take a second to picture a food plant. Sticky sauces build up quick. A ball valve jams. But a diaphragm one? It wipes clean with a rinse. Or in chems—acids chew metal fast. Here, the seal holds without touching the flow. I’ve heard stories from old-timers. They say it changed their whole shift rhythm. Less panic over leaks. More focus on output.

Key Factors for Picking Your Diaphragm Valve

Okay, let’s hit the main stuff. How do you choose one that won’t strand you? Begin with the starts—body material and diaphragm type. Then add the extras. It’s like stocking a kit. The best mix tackles any task you hit.

Body Materials: The Foundation That Fights Back

The body is your first line against push, heat, and what’s moving through. Choose poorly. Cracks or wear hit quick. Like “oops, shutdown.” Folks often go for stainless steel. It’s tough against rust. Or cast iron for basic cash saves. But wait— in a briny salt line, plain steel twists in half a year. Seen it at shore-side spots. Valves turn holey like old cloth.

For a straight look, here’s a table on top body picks and their strong suits:

|

Body Material |

Best For |

Pressure/Temp Limits (Typical) |

Drawbacks |

Cost Ballpark |

|

Stainless Steel (316L) |

Harsh chems, drug clean areas |

Up to 150 psi / 300°F |

Bigger start price |

$$ $ |

|

Cast Iron |

Water cleanup, light-grind flows |

Up to 200 psi / 400°F |

Weak in sour stuff |

$ |

|

Alloy 20 |

Strong acid jobs |

Up to 100 psi / 250°F |

Too much for easy tasks |

$$$$ |

|

PVC/Plastic |

Easy-push sour lines |

Up to 150 psi / 140°F |

Bad for hot runs |

$$ |

Stainless leads in seven out of ten shop fits, from vendor tallies. It shrugs off salt bits. But on a lean budget? Cast iron works fine in flat waters. Just skip it with ammonia. That mix spells trouble.

And think about a real shift. Say you’re in paints. Solvents eat cheap metal. Switch to stainless. No more mid-run patches. Output stays steady. That’s the win.

Diaphragm Types: The Heart of the Seal

Next up, the diaphragm proper. That’s the key call. You face two big kinds: weir-style and full-path. Weir acts like a low hill in the stream. The diaphragm squeezes a raised edge for a tight close. It’s small. Uses slim stuff. And takes big pushes without thinning out. Full-path? Smooth ride all the way. No hills. So heavy mixes slide easy. But it needs a thicker, stretchier diaphragm. That one tires sooner in warmth.

- Weir-Type Diaphragms: Great for fine tweaks on tiny streams or pull jobs. The middle lift offers sharp handle. Like adjusting a tap slow. In snack lines, this drain angle fights germs. Imagine a candy shop. Syrup sticks bad. These keep it clear. No hour-long scrubs.

- Full-Path Diaphragms: Made for dense loads like rock mush. Stream flows free. But mind the heat. Past 200°F, the soft bend hardens. A pal in gravel work switched to these. Balls kept locking up. Their rates shot up a quarter. True story.

On stuff, EPDM gum holds waters strong. PTFE— that’s Teflon—ignores acids. Wrong match? Life drops from seasons to weeks. Quick hint: For mix jobs, stacked diaphragms (gum under PTFE) link bend with sour smarts. They fit odd spots well.

Ever wonder why some plants stock both? One site’s got clean brews. Another hauls dirt. It pays to test small. Saves big later.

Beyond Basics: Size, Pressure, and Connections

Skip the fine print at your peril. Size? Line it with your tube. Too tight? Push falls and eats power. Too loose? Cash down the drain. Push scores rise with weir builds. They hit 150 psi smooth. Full-path caps at 100 for thick hauls. Link ends? Bolted for fat tubes. Screwed for fast changes. At a beer house redo, wrong bolts stretched a quick fix to full day. Ouch. Always match the plans twice.

Pressure isn’t just a number. It ties to safety. Say a line hits spikes. Under-rated body? Boom—risk. I’ve seen audits where that bit a firm hard. Fines piled up. So check charts close.

Connections too. In tight spots, clamp styles snap in. No tools needed. Beats wrench fights every time.

Real-World Applications: Where Diaphragm Valves Shine

Talk is cheap. Let’s hit the floor. In drug work, weir stainless with PTFE seals keep lines spotless. No hidey holes for bugs. A standard rig might push 50 gallons a minute of med mix. Holds pull at -14 psi. Not a peep.

Flip to chems. Alloy bodies with EPDM faces chew 98% sour flows at 180°F. One yard I caught wind of ditched slide valves. Leaks fell 40%. Crews thinned out smart.

Food and drinks? Full-path plastics for fruit squeezes. They scrub easy for fed stamps. Mining’s wilder. Grind-proof faces in iron bodies munch ore slop. Throughput climbs 15% some places. These come from job files. Right choice cashes in.

But it’s not all smooth. Take a dairy run. Milk sours quick if seals slip. A weir valve here? It drains full. No puddles for bugs. Saved one outfit from a bad batch recall. Cost? Thousands. Lesson sticks.

Or pharma trials. Small batches need fine flow. Throttle wrong, and purity tanks. Diaphragm’s partial press nails it. Labs swear by ’em now.

Pitfalls to Dodge When Buying

We’ve all rushed a list. Ended with gear that folds fast. Big miss: Skipping flow match. That bright stainless? Dead vs fluorides sans alloy fix. Or cheap on spare faces. One rip, line halts. Another: Missing drive type. Hand-turn saves bucks. But air-push quickens auto lines. Like in bottle fills. Seconds add up.

Yeah, low bids tempt. A fair seller cuts 20%. But if build slips, fix fees triple it. From seller yarns, certified teams save grief over time.

And don’t forget stock. Rush order? Weeks wait. Plan ahead. One plant learned hard—downtime hit profits square.

Test samples too. Run ’em in your mix. See wear real. Beats guesses every day.

Meet Miwival: Your Go-To Diaphragm Valve Partner

When sourcing trusty diaphragm valves, Miwival pops as a keen provider. Deep in flow steer. Started on quality bedrock. They earned stripes for valves that hit—or top—hard bars like ISO 9001. Each bit faces a tough run. From sour scans on fresh pours to push bursts and no-harm probes. No soft spots slip by. Their crew, full of flow sharpies, sells more. They hear you out. Tweak builds for your spot-on need. Be it weir for drug tight or full-path for mush drags, Miwival’s stock fits. All with stuff papers back to start. That close feel—world span with home smarts—keeps yards humming.

What sets ’em apart? Quick turns. Custom tweaks without the wait. And that test grind? It catches flaws early. Plants lean on it for peace.

Wrapping It Up: Your Next Step in Valve Savvy

Picking the right diaphragm valve comes down to lining body material and diaphragm type with your stream’s needs. Sour snap or mush drag. We’ve walked the whys and ways. From stainless that bats away acids to weir that tweaks like champs. Grab these bits. Dodge the flops. Land a rig that lifts work sans fuss. Next spec time, keep this: It’s no mere valve. It’s the door to slicker runs.

One last nudge. Chat your team. Run numbers on fits. It seals the deal.

Frequently Asked Questions

What should I consider first in a buyer’s guide to selecting the right diaphragm valve?

Kick off with your stuff—sours, mushes, or plain water? Then pair body like stainless for sour hold. Diaphragm type next: Weir for tweaks. Full-path for stream.

How does body material impact diaphragm valve performance?

It’s the guard vs wear. Stainless takes chems sans holes. Cast iron trims cash for soft jobs. Choose on heat and push. Wrong one? Drips chase fast.

What’s the difference between weir and straight-through diaphragm types?

Weir squeezes a lip for firm shuts and tiny tweaks. Suits pulls. Full-path lets all slide. Fits dense like sludge. But they bend more. Wear quick in warmth.

Can I use the same diaphragm valve across industries like pharma and mining?

Not off-shelf. Drug wants clean stainless with PTFE faces. Mining needs grind-tough alloys. Shape it—body and type—to skip pricey flips later.

Where do I find reliable diaphragm valves with solid quality backing?

Hunt teams like Miwival. They grind full checks from pour to pack. Papers and know-how keep your buyer’s guide pick tough in the daily grind.