Advantages and Limitations of Butterfly Valve in Industrial Applications

Butterfly valves are essential in fluid management setups. They offer space savings, economy, and speedy action. Their quarter-turn operation and small size make them perfect for many fields, from water purification to chemical handling. While they perform well with small pressure loss and fit automation easily, issues like pressure boundaries and flow regulation exactness need attention. Miwival improves these benefits with customized answers, guaranteeing dependability in tough industrial settings.

What Are Butterfly Valves and How Do They Function in Industrial Systems?

Butterfly valves are vital parts in fluid management setups. This is especially true in industrial uses where room, effectiveness, and price are key concerns.

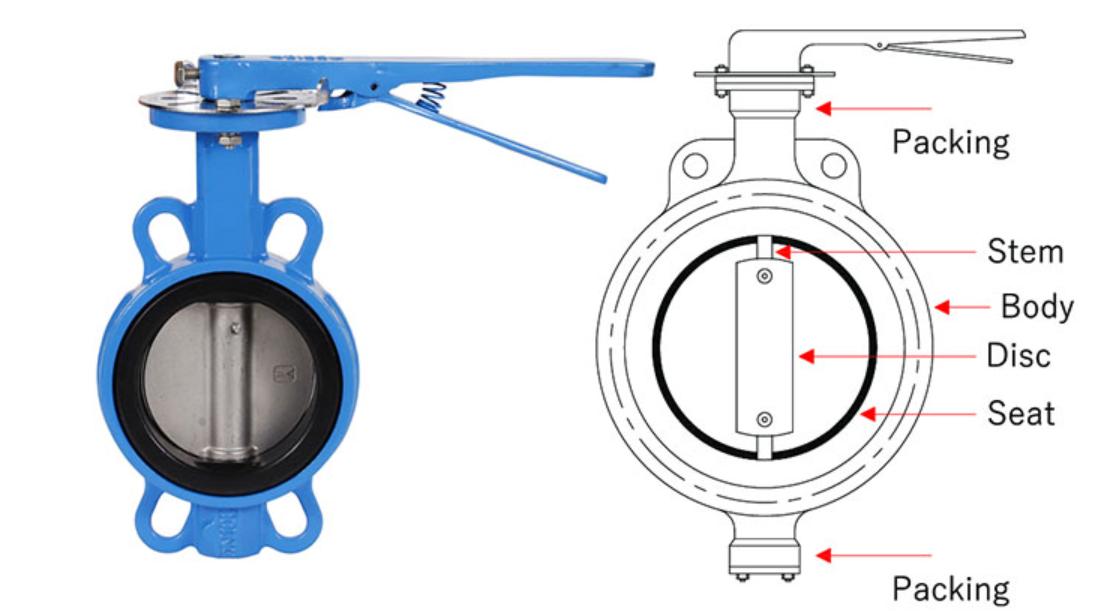

Basic Structure and Components of a Butterfly Valve

A butterfly valve mainly has a round plate mounted on a turning rod. This plate sits in the middle of the pipe and spins to control movement. Important parts include:

- Outer casing (holding the internal pieces)

- The plate (blocking or permitting movement)

- The shaft (linking the operator to the plate)

- The seal (creating closure between plate and casing)

These pieces work together to ensure dependable stopping and flow adjustment abilities.

Operating Mechanism and Flow Control Capabilities

The valve works by spinning the plate one-quarter turn to open or shut it. When fully open, the plate lines up with the flow path, giving little resistance. When shut, it sits crosswise to stop movement entirely. This quarter-turn action allows rapid functioning with minimal turning force. This makes butterfly valves perfect for both complete closure and moderate flow adjustment jobs in pipelines.

Common Materials Used in Manufacturing

Butterfly valves are built from various substances depending on application demands. Frequent casing substances include:

- Cast iron

- Ductile iron

- Stainless steel

- PVC

Plates might be made from aluminum bronze or stainless steel for rust prevention. Seals are often elastic materials like EPDM or PTFE for tight closure.

Miwival tackles these working basics by providing butterfly valves made with strong substances and exact mechanisms made for challenging industrial conditions.

Why Are Butterfly Valves Widely Used in Industrial Applications?

Butterfly valves have become common in industrial uses because of their effective design, low cost, and flexibility across areas from water treatment to chemical work.

Compact Design and Space Efficiency

Their thin shape allows fitting in tight spots without reducing performance. Unlike gate or globe valves that need significant room for operation, butterfly valves work well with little space needed.

Cost-Effectiveness Compared to Other Valve Types

Butterfly valves usually involve fewer pieces and simpler building than other kinds like ball or globe valves. This means lower production expenses and decreased upkeep costs over time. These are important benefits in large industrial arrangements.

Quick Operation and Low Torque Requirement

The quarter-turn design ensures fast opening and shutting cycles with minimal work or operator power. This makes them fitting for automatic systems where velocity is necessary.

Versatility Across Various Industrial Sectors

Butterfly valves are used widely across businesses such as:

- Oil & gas

- HVAC

- Food preparation

- Drug making

- Pulp & paper

- Ship systems

This is due to their adaptability with different liquids and working states.

Miwival backs this flexibility by giving a wide selection of setups made for different fluid kinds and pressure levels used throughout varied industrial applications.

What Are the Key Advantages of Using Butterfly Valves?

Besides their broad usefulness, butterfly valves offer several working benefits that boost arrangement performance while lowering lifetime costs.

Lightweight Construction for Easy Installation

Their small size also leads to less weight compared to other valve kinds. Lighter assemblies simplify moving and fitting steps. This is especially important when updating existing lines or working up high.

Minimal Pressure Drop During Operation

When fully open, butterfly valves present little blockage to movement. The smooth form of the plate ensures small pressure loss across the valve body. This is a key element in keeping energy efficiency within pumping arrangements.

Simple Maintenance Requirements

Fewer moving pieces mean less wear over time. Many designs permit inline upkeep without taking the whole valve out of service. This is a major benefit during planned plant stops or urgent fixes.

Compatibility with Automation Systems

Butterfly valves combine easily with electric or air-driven operators for distant control. Their quick reaction time makes them perfect choices for automatic process management systems needing precise adjustment under changing states.

Miwival uses these benefits by supplying automation-ready butterfly valves planned with lasting dependability and simple serviceability in mind. This reduces downtime while improving working control.

What Limitations Should Be Considered When Using Butterfly Valves?

Despite their many strengths, butterfly valves do have limits that must be thought about during arrangement design. This is especially true when dealing with severe states or special fluids.

Suitability for High-Pressure Applications

Standard butterfly valves might not resist very high-pressure settings due to their relatively thin plates and soft seals. For such cases, specially strengthened high-performance designs must be chosen.

Potential for Leakage Around the Disc Seal

Soft-seated butterfly valves can experience leaking if dirt gets in the way of closing surfaces. Leaks can also happen if seals break down over time under chemical contact or heat changes.

Restricted Throttling Accuracy in Some Conditions

While able for moderate flow control duties, butterfly valves might show uneven movement traits at partial openings. This can limit exactness where fine movement adjustment is needed. This is especially true compared to globe valves made specifically for flow control precision.

Material Compatibility with Harsh Media

Strong chemicals or rough mixtures can wear standard substances quickly unless proper metal mixes or coverings are used. Therefore, careful choice based on fluid properties is vital during specification phases.

Miwival helps reduce these difficulties through special substance choices and modern closing methods made specifically for tough working settings common in industrial applications.

How Do Different Types of Butterfly Valves Perform Under Varying Conditions?

Choosing between different structural designs affects how well a butterfly valve acts under particular pressures, temperatures, flow volumes, and fitting limits.

Concentric vs. Eccentric Designs

Concentric (or zero offset) designs place the rod at the centerline of both pipe and plate. They are perfect for low-pressure systems using soft seals. Eccentric designs (single-, double-, triple-offset) shift rod placement away from centerlines. This lessens rubbing during use. This allows use at higher pressures and temperatures with metal-to-metal closing choices.

Lug Type vs. Wafer Type vs. Flanged Ends

Wafer-style casings fit between flanges using long bolts. Lug-style versions have threaded holes allowing disconnection downstream without affecting upstream lines. Flanged ends provide full-face bolting matching preferred in heavy-duty fittings needing stiffness or frequent removal access.

Miwival offers all main setups including concentric/offset shapes as well as wafer/lug/flanged bodies. This ensures best performance no matter of arrangement layout or mechanical limits within industrial applications.

How to Select the Right Butterfly Valve for Specific Industrial Needs?

Proper choice ensures dependable performance while avoiding early failure due to mismatched specifications. This is a key task when planning complex fluid arrangements.

Evaluating Pressure and Temperature Requirements

Understanding highest working pressure (PN rating) and heat span helps decide if soft-seated concentric designs are enough. It also shows if metal-seated eccentric models are needed instead.

Considering Media Characteristics (Corrosive, Abrasive, etc.)

Fluid makeup guides substance choices. Stainless steel fights rust. Rubber linings take in shock. Special coverings withstand scraping. These are all vital thoughts when handling chemicals, mixtures, or gases under changing pH levels or particle loads.

Assessing Operational Frequency and Flow Control Demands

Frequent cycling calls for strong operator mechanisms. Precise adjustment needs designs offering straight control lines. Emergency stopping requires quick reaction times. All these factors affect operator choice as well as internal shape selection.

Miwival makes this decision process easier by offering engineering support backed by wide field knowledge. This ensures each product meets strict technical rules across all industrial applications met by customers globally.

How Does Miwival Support Industrial Operations with Reliable Butterfly Valves?

As a knowledgeable supplier focused on quality-driven answers made specifically for industry needs, Miwival stands out through its product variety depth and promise to engineering skill across fluid control methods known worldwide today.

Overview of Miwival’s Product Range and Technical Expertise

Miwival gives a full collection covering concentric and eccentric types. It includes wafer, lug, and flange mountings. Choices include manual, air-driven, and electric operation. All are built upon years-long skill supporting vital building projects worldwide.

Quality Assurance Standards and Certifications Held by Miwival

Each Miwival product follows international rules like ISO 9001 quality systems. They also have CE marks where needed. This ensures steady performance under regulated settings.

Industries Served and Customization Capabilities

From water cleaning sites to petrochemical plants—and everything in between—Miwival serves customers across many fields. It offers made changes including special linings, coverings, and substances suited exactly for customer-specific process needs within industrial applications.

Summary of Key Points on Butterfly Valve Usage in Industry

Butterfly valves offer light building combined with quick action. This makes them perfect picks across many areas. However, they need careful choice based on pressure, fluid, and flow adjustment demands. Miwival addresses these through customizable answers built around real-world working challenges.

What Are Some Frequently Asked Questions About Butterfly Valves?

What is the maximum pressure rating typically supported by butterfly valves?

Standard concentric designs handle up to 16 bar (232 psi). High-performance triple-offset models can go beyond 100 bar depending on building substances used.

Can butterfly valves be used for both throttling and isolation purposes?

Yes. They are excellent at closure jobs due to tight shutting ability. However, they give only moderate exactness when used constantly as flow control devices.

Are butterfly valves suitable for handling slurries or viscous fluids?

They can be. This requires proper substance choice like rubber-lined casings and plates. These are made specifically against wear caused by floating solids within thick streams found often in mining, pulp, and petrochemical areas.