Check Valve Fundamentals: Understanding Its Mechanism and Function

Check valves, also called non-return valves (NRVs), one-way valves, or reflux valves, are vital parts in fluid systems across many fields like oil and gas, water treatment, and pharmaceuticals. These apparatuses guarantee fluid travels in one direction. They stop backward movement that might harm gear or weaken system effectiveness. This blog explores the essentials of check valves deeply. It looks at their working parts, jobs, kinds, and uses. This helps you grasp their significance and choose wisely for your setups. Whether you oversee a place, are an engineer, or buy gear, this guide offers helpful knowledge to improve your activities.

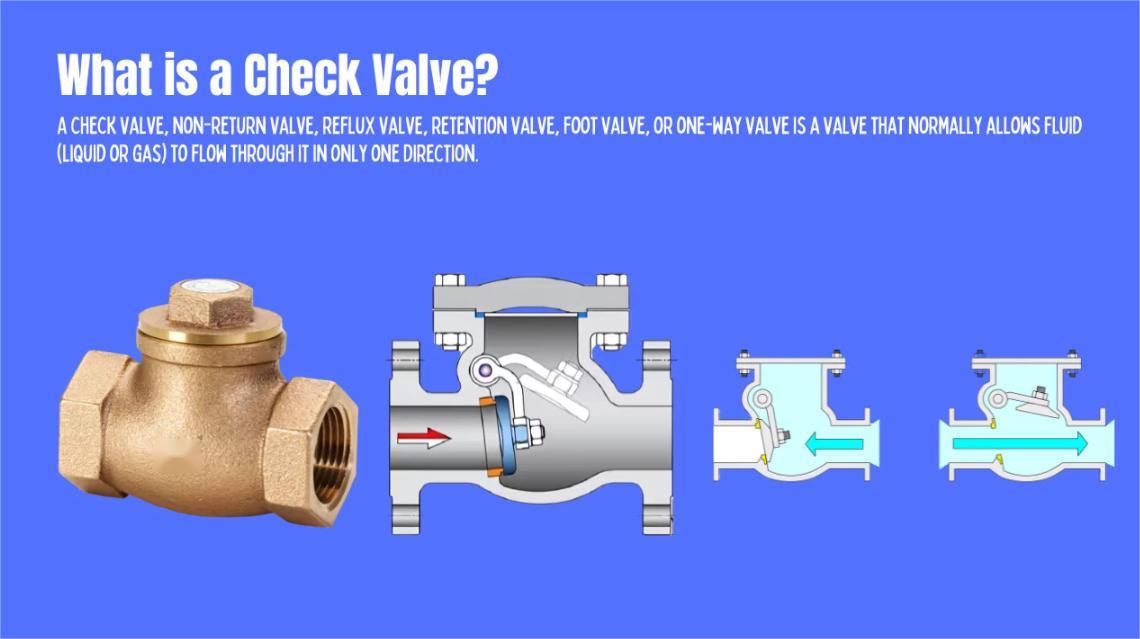

What is a Check Valve?

A check valve is a mechanical part made to let fluid or gas move in one direction. It blocks opposite travel. This one-way movement control is crucial. It shields pumps, compressors, and pipe networks from the destructive results of backward flow. Backward movement can cause gear breakdown, pollution, or pressure decrease. Check valves function by themselves. They depend on the pressure difference between the input and output sides to open or shut.

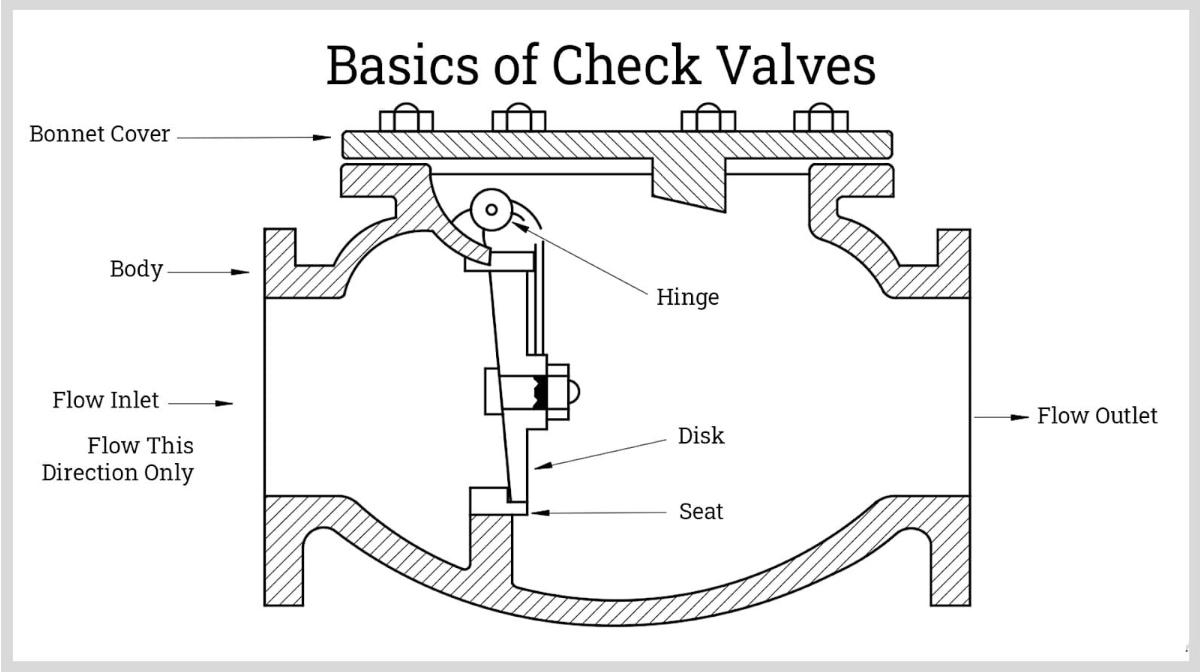

Key Parts of a Check Valve

Knowing the pieces of a check valve is key to understanding its operation. The main pieces include:

- Body:The central frame holding all pieces. It has entry and exit points for fluid movement.

- Disc:A shifting piece that opens to permit movement and shuts to block backward flow.

- Seat:The surface where the disc closes to make a firm seal.

- Hinge Pin:Found in swing check valves. It lets the disc turn.

- Springs:Present in spring-loaded check valves. They help closing and keeping the seal.

- Covers/Bonnets:Allow access for upkeep and help contain the substance.

Extra pieces, like filters in foot valves or movers in stop check valves, add features for particular jobs.

How Check Valves Work

Check valves depend on two core ideas: cracking pressure and the opening/shutting method.

Cracking Pressure: This is the smallest input pressure needed to open the valve. It must beat resistance from springs, gravity, or the disc’s heaviness. For example, a lift check valve requires enough pressure to raise the disc upward against gravity or spring force.

Opening/Closing Method: When input pressure passes output pressure, the valve opens. This lets fluid go through. If the output pressure grows larger or movement halts, the valve shuts by itself. The shutting method differs by valve kind—discs swing in swing check valves, while balls shift in ball check valves.

This self-acting operation provides reliability without human help. This makes check valves perfect for important systems.

Main Functions of Check Valves

Check valves carry out three key jobs that boost system safety and productivity:

- Preventing Backward Flow:By stopping opposite movement, check valves guard systems from pollution or pressure spikes. For instance, in water cleaning places, they stop cleaned water from mixing with dirty water.

- Shielding Gear:Backward flow can make pumps or compressors spin backward. This leads to mechanical harm. Check valves lessen this danger, lengthening gear life.

- Keeping System Soundness:By ensuring one-way movement, check valves maintain steady pressure and stop substance mixing. This is vital in fields like pharmaceuticals where purity is critical.

Types of Check Valves

Check valves come in many designs. Each fits special jobs. Below is a table summarizing the most common kinds, their traits, jobs, and benefits/drawbacks:

|

Type |

Traits |

Jobs |

Benefits |

Drawbacks |

|

Swing Check Valve |

Hinged disc, very small pressure drop |

Water supply, dirty water systems |

Straightforward, cheap, easy upkeep |

Slow shutting, danger of pressure surge |

|

Lift Check Valve |

Up/down disc/ball shift, great pressure |

Oil and gas, high-pressure setups |

Firm closing, flexible position |

Bigger pressure drop, more upkeep |

Each kind fits particular situations, like high-pressure setups (lift check valves) or clean jobs (diaphragm check valves). Picking the correct kind depends on your system’s demands.

Stuff Used in Check Valves

The stuff choice greatly affects a check valve’s performance, sturdiness, and fit with the substance. Common stuff include:

Metal Stuff

- Stainless Steel:Gives strong rust resistance. Perfect for chemical handling and sea settings.

- Brass:Affordable and rust-resistant. Good for low-pressure setups like home water supply.

- Cast Iron:Low-cost for average conditions. Used in water supply but can rust.

- Ductile Iron:Tougher and longer-lasting than cast iron. Used in high-pressure jobs with coverings for rust resistance.

Non-Metal Stuff

- PVC (Polyvinyl Chloride):Light and rust-resistant. Used in watering and low-pressure chemical setups.

- Polypropylene:Better chemical resistance. Fits destructive substances like acids and cleaners.

Picking the proper stuff makes sure the valve holds up against the substance’s chemical traits, heat, and pressure.

Choosing Rules for Check Valves

Choosing the proper check valve needs careful thought about many things:

- Substance Traits:Find out if the substance is liquid, gas, or thick mix. For instance, ball check valves are great for thick mixtures because they clean themselves.

- Pressure and Movement Demands:Make sure the valve’s cracking pressure matches system pressure. Tilting disc valves fit high-speed flows due to small pressure loss.

- Setting Things:Match stuff to heat and chemical fit. Stainless steel is great for high heats, while PVC suits low-heat jobs.

- Fitting Thoughts:Think about position (flat/straight) and space limits. Wafer check valves are ideal for tight spots.

Proper choice improves system productivity and stops expensive breakdowns.

Fitting and Upkeep Top Methods

Correct fitting and upkeep are essential for the best check valve performance and long life.

Fitting Tips

- Position:Line up the valve with the movement direction shown by the arrow on the frame. Make sure proper position based on valve kind (e.g., lift check valves for flat setups).

- Avoid Churning:Fit the valve away from pumps, bends, or junctions to reduce churning.

- Checking:Do after-fitting checks to confirm proper opening, shutting, and sealing.

Upkeep Rules

- Regular Checks:Look for wear, rust, or dirt buildup twice a year.

- Cleaning:Remove sludge or dirt from the valve frame and parts.

- Piece Swap:Replace worn seals, springs, or discs as needed.

- After-Upkeep Checking:Use water or air pressure checks to confirm function after upkeep.

Common Problems and Fixes

Check valves can face problems that harm performance. Here are common troubles and answers:

- Pressure Surge:Caused by fast valve shutting, leading to pressure spikes. Use non-slam check valves with spring-loaded discs to reduce this.

- Opposite Movement:Results from poor sealing due to wear or dirt. Spring-help check valves and regular cleaning stop this issue.

- Too Big:A valve too large for the system may not open fully, causing shaking. Pick the right size based on movement speed and line size.

- Fitting Mistakes:Wrong position or nearness to churning sources can lower performance. Follow maker rules and make sure proper spacing.

Fixing these troubles quickly keeps system reliability.

Miwival: Your Reliable Check Valve Supplier

Miwival is a top provider of high-standard check valves and automation answers. They offer a full set of goods made for fields like pulp and paper, mining, water treatment, and power making. With attention to standard, price, delivery, and help, Miwival’s check valves meet strict rules like API 594 and ASME B16.34. This ensures fit and reliability. Their well-taught team gives personal support. They help you pick the proper valve for your job. Visit miwivalve.com to see their products and ask for a price.

Conclusion

Check valves are indispensable for ensuring one-way movement, shielding gear, and keeping system soundness across many fields. By knowing their working parts, kinds, stuff, and choosing rules, you can pick the proper valve to improve performance and stop costly troubles like backward flow or pressure surge. Correct fitting and regular upkeep further boost valve life and system productivity. Teaming with a reliable provider like Miwival makes sure you get high-standard check valves that meet field rules and your special needs.

FAQs

What is the main job of a check valve?

A check valve’s main job is to stop backward movement in a pipe system. It makes sure fluid travels in one direction. This shields gear like pumps and keeps system soundness by stopping pollution or pressure loss.

How does cracking pressure change check valve performance?

Cracking pressure is the smallest input pressure needed to open a check valve. If the system’s pressure is below this level, the valve won’t open. This might break up movement. Picking a valve with a suitable cracking pressure is vital for productive operation.

Which kind of check valve is best for high-pressure setups?

Lift check valves and tilting disc check valves are ideal for high-pressure setups. This is because of their firm sealing and ability to manage high speeds. Always match the valve’s pressure rating to your system’s demands.

How can I stop pressure surge in a check valve?

To stop pressure surge, use non-slam or spring-loaded check valves. These close slowly to lower pressure spikes. Proper valve sizing and keeping best movement speeds also help reduce this trouble.

Why is stuff choice important for check valves?

Stuff choice makes sure the check valve holds up against the substance’s chemical traits, heat, and pressure. For example, stainless steel is great for destructive settings, while PVC suits low-pressure, non-destructive jobs.