Common Desuperheater Problems & How to Fix Them (With Case Studies)

Think about a steam system working well, giving its best to run your factory tasks. Suddenly, things go wrong because of changing heat levels or worn parts. Desuperheaters, important parts in areas like making electricity, handling chemicals, and producing sugar, are built to keep steam heat exactly right. But when troubles start, they can cause expensive stops and waste. This blog looks closely at frequent desuperheater troubles, hands-on answers, and actual examples. It includes thoughts on how Miwival’s top-notch desuperheaters provide steady work and good results.

What Is a Desuperheater and Why It Matters

A desuperheater is a key piece in steam setups. It lowers the heat of very hot steam to the needed level by adding cool water or another substance. This step makes sure steam fits later uses. It also protects parts like turbines and pipes from heat strain. In fields such as power, chemicals, and paper making, exact steam heat control is essential for saving effort and staying safe. Miwival, a trusted brand for industrial valve answers, makes desuperheaters that meet the tough needs of these areas. They promise lasting use and good function under high force and heat.

The Role of Desuperheaters in Industrial Processes

Desuperheaters are vital for keeping work steady in steam systems. By managing steam heat, they stop too much heating. This can harm parts. They also make sure heat moves well for tasks like making power or chemical actions. Miwival’s desuperheaters, for example, are built to deal with severe settings. They offer strong answers for areas like cement, steel, and food making.

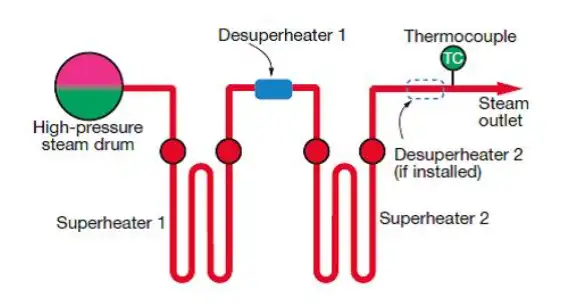

How Desuperheaters Work

Desuperheaters work by putting a set amount of cool water into very hot steam. This drops its heat through turning to vapor or direct touch. The method needs careful control to avoid troubles like water moving on or heat shock. Miwival’s plans use new nozzle tech and heat sleeves. This ensures good mixing and turning to vapor. It lowers dangers to parts further down the line.

Common Desuperheater Problems and Their Impact

Desuperheaters, while needed, can face several troubles that upset how the system works. These issues often come from bad design, setup, or care. This leads to waste or part failure. Below, we look at the most usual desuperheater troubles, their reasons, and their effect on factory work.

Thermal Fatigue and Cracking

Thermal fatigue happens when desuperheater parts face quick heat shifts. This causes strain and finally cracks. For instance, repeated wetting from badly turned to mist boiler feedwater can create heat strain changes in piping. This leads to breaks. This trouble is especially common in combined-cycle sites with many starts and stops.

Impact:

Cracked pipes or nozzles can lead to steam leaks, unplanned stops, and pricey fixes. Downtime might cost sites $200,000–$250,000 each day.

Improper Spray Atomization

Poor turning to mist of cool water can cause uneven cooling. This makes water drops hit pipe walls straight on. It leads to heat shock and possible cracking. This is especially true in high-strain spots like areas near nozzles.

Impact:

Bad turning to mist cuts desuperheater efficiency. It raises wear on parts further down. It also risks damp steam getting into turbines. This can cause wearing away or harm.

Control Valve Leakage

Control valves in desuperheaters, often set with Class IV shutoff, might leak under high force differences. This allows unwanted water flow during start or stop. This can lead to damp steam or heat shock in systems further down.

Impact:

Valve leakage messes up exact heat control. It raises energy use. It also risks part harm because of wrong steam states.

Temperature Differentials in Piping

Big heat differences between the top and bottom parts of desuperheater piping can cause lengthwise bending and changing shape. This problem often results from poor design or setup. It leads to hanger support failures or pipe strain.

Impact:

Pipe changing shape can weaken system soundness. This leads to leaks, lower efficiency, and costly fixes or swaps.

Miwival tackles these frequent desuperheater troubles through exactly built designs. They use new metal science and heat sleeves to lessen thermal fatigue and cracking. Their nozzles promise great turning to mist. Meanwhile, high-grade control valves lower leakage dangers. This ensures steady results across areas like power, sugar, and chemical handling.

How to Fix Common Desuperheater Problems

Solving desuperheater troubles needs a mix of good parts, proper setup, and strict care. Below are hands-on answers to the troubles covered. They are made to promise long-term system steadiness.

Mitigating Thermal Fatigue

To lower thermal fatigue, make sure desuperheaters are designed for high-heat settings (up to 1,150°F) and cycling work. Using new metal science, as Miwival does, makes parts last longer. Regular checks during stops can find early signs of cracking. This allows for fixes on time.

Solution Steps:

- Put in heat sleeves to guard piping from heat shock.

- Use desuperheaters with stuff fit for high-heat steam, like those from Miwival.

- Do regular inside checks using new test tools.

Improving Spray Atomization

Proper nozzle design is key for good turning to mist. Miwival’s desuperheaters have single- or many-point side injection nozzles. They promise fine water spread. This helps fast turning to vapor and lowers heat shock.

Solution Steps:

- Move to high-grade nozzles made for even turning to mist.

- Ensure proper nozzle spot (2–8 pipe widths upstream, 12–20 downstream).

- Check nozzles often using movable test rigs to keep results.

Addressing Control Valve Leakage

Putting block valves upstream of control valves can stop leakage. This is especially true in sites with several heat-recovery steam makers (HRSGs). Miwival’s desuperheaters include strong valve designs. They promise tight shutoff under high force states.

Solution Steps:

- Put in worked block valves for sure separation.

- Regularly check and care for control valves to stop wear.

- Use Miwival’s high-result valves made for tight shutoff.

Managing Temperature Differentials

To stop pipe changing shape, ensure proper support and hanger design. This must handle heat growth. Miwival’s building group gives custom answers. They rework pipeline loads to stop support troubles.

Solution Steps:

- Rework pipeline supports to spread loads evenly.

- Use heat sleeves to keep steady pipe heats.

- Watch heat slopes during work to change water flow speeds.

Case Studies: Real-World Solutions in Action

Actual cases show how solving desuperheater troubles can lift system results. Below are two case studies showing useful answers.

Case Study 1: Combined-Cycle Power Plant

Problem:

A combined-cycle site had frequent nozzle failures due to poor turning to mist. This led to damp steam and turbine harm. The site faced stops costing $200,000 daily.

Solution:

The site updated Miwival’s high-heat desuperheater with new side injection nozzles. The fresh design promised proper turning to mist. It kept steam heats above 1,050°F without getting worse.

Outcome:

After five years, the site told of no leaks or nozzle failures. This saved large sums in downtime costs. It also made turbine steadiness better.

Case Study 2: Chemical Processing Facility

Problem:

A chemical site faced pipe changing shape due to heat differences in the desuperheater part. This caused hanger failures and weld cracks.

Solution:

Miwival’s group reworked the pipeline supports. They also put in heat sleeves to lower heat strain. They added a feedforward control setup to expect heat shifts and change water flow early.

Outcome:

The place got rid of hanger supports and weld cracks. It reached steady work. It also cut care costs by 30%.

Miwival: A Leader in Desuperheater Solutions

Miwival focuses on high-result desuperheaters for areas like steam, mining, water and wastewater, paper making, steel, chemical, sugar, power, fertilizer, food and drink, palm oil, and cement. With over 30 years of skill, Miwival gives answers that focus on quality, lasting use, and exactness. Their desuperheaters are made to hold up under severe states. They use new metal science, exact nozzle plans, and strong control setups to solve frequent desuperheater troubles well. By picking Miwival, industries gain from steady, energy-saving answers made for their own work needs.

Conclusion

Desuperheaters are key for keeping steam systems saving effort and safe. But troubles like thermal fatigue, poor turning to mist, valve leakage, and heat differences can upset work. By spending on high-grade parts, proper setup, and early care, industries can lessen these tests and lift system steadiness. Miwival’s desuperheaters stand out for their strong design and exact building. They offer answers that tackle the root reasons of frequent desuperheater troubles. Through actual case studies, we’ve seen how their answers give clear gains, from cost cuts to better results.

FAQs

What are the most common desuperheater problems in industrial settings?

Frequent desuperheater troubles include thermal fatigue, poor spray turning to mist, control valve leakage, and heat differences in piping. These issues can lead to part harm, waste, and costly downtime if not fixed quickly.

How can I prevent thermal fatigue in my desuperheater?

To stop thermal fatigue, use desuperheaters made for high-heat settings, like those from Miwival. They use new metal science and heat sleeves. Regular checks and proper setup also help lessen strain and cracking.

Why is proper spray atomization critical for desuperheater performance?

Proper spray turning to mist ensures even cooling and fast turning to vapor. This stops heat shock and damp steam. Miwival’s new nozzle plans reach even turning to mist. This protects parts further down and lifts efficiency.

How does Miwival ensure the quality of its desuperheaters?

Miwival uses top-grade stuff, exact building, and strict tests. This makes sure their desuperheaters meet the demands of areas like power, chemical, and sugar. Their plans solve frequent desuperheater troubles. This promises lasting use and steadiness.

Partner with Miwival for Reliable Steam Solutions

Don’t let desuperheater troubles weaken your work. Miwival offers top desuperheaters made to handle thermal fatigue, poor turning to mist, and valve leakage. They promise the best results and long life. Look at our range of answers at miwivalve.com and talk to our group to make a setup that fits your special needs. Spend on quality, cut downtime, and lift efficiency with Miwival today.