Exploring the Versatility of Miwival Ball Valves in Industrial Settings

What Makes Miwival Ball Valves Essential in Industrial Applications?

Factories need tools they can trust, that work well, and that keep people safe. Miwival ball valves give these things through smart design and strong building. They control liquid flow very precisely while holding up under hard conditions. This makes them a top pick in many different fields. Next, we look at the main features and working benefits that make these valves stand out.

Core Features of Miwival Ball Valves

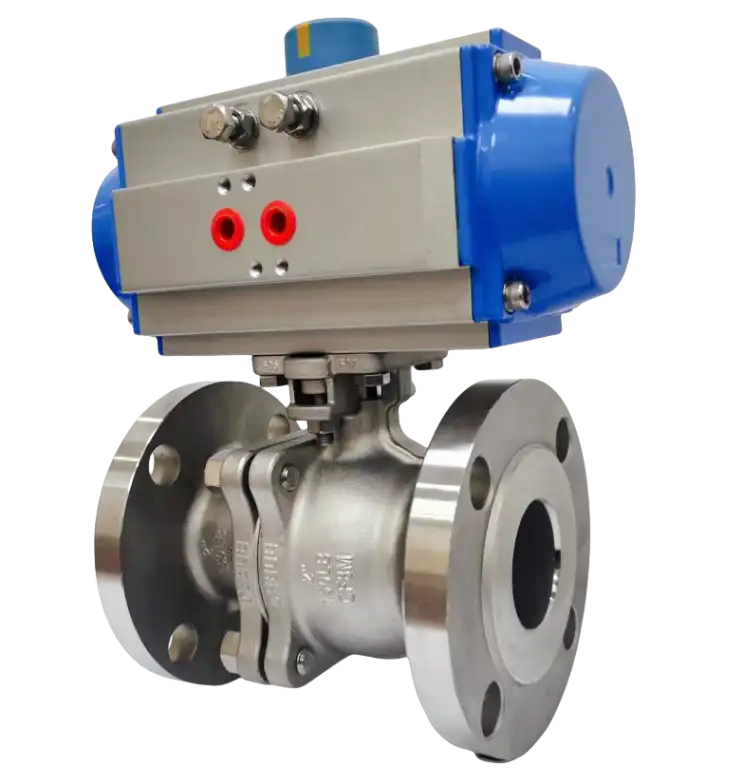

Miwival ball valves are known for their tough build, exact design, and ability to handle difficult factory places. They are made to control how liquids and gases move with great accuracy. The main parts include a round ball with a hole in the middle. Turning this ball controls the flow. These valves are built using strong stuff like stainless steel, brass, or other metals that fight rust. This helps them last long and work well.

The seals in Miwival ball valves use new ideas to stop leaks, even when pressure is very high. Their small size fits well in tight spots while still working great. Also, these valves often have parts to stop sparks and designs that resist fire. This makes things safer in important jobs.

Key Benefits in Industrial Operations

From standing up to huge pressure to needing little care, Miwival ball valves give big pluses that help factories make more. They control flow well and save energy. This makes them key for saving money. Here, we point out the main benefits that explain why so many people use them.

Strength and Trust in Hard Places

Miwival ball valves do great in spots with very hot or cold temps, eating-away corrosive stuff, and high pressure. Their strong build means little wearing out over many years of use. The stuff they use fights chemical changes. This makes them perfect for areas like oil and gas work, chemical plants, and water cleaning buildings.

You can count on these valves because they need little care. Workers trust them to work the same way every time without lots of fixes or changes. This strength means less stopping work and helps keep factory jobs running.

Good Flow Control Ways

One big plus of Miwival ball valves is how well they control flow. A quarter-turn opens or shuts them fast. This allows exact control over how much liquid moves. This good working cuts down on lost energy. It makes sure the system works at its best.

These valves also seal very well. This stops leaks that could waste stuff or harm nature. Their power to close tightly makes them a favorite for jobs needing strict flow rules.

How Do Miwival Ball Valves Make Work Better?

Working well is key for factory success. Miwival ball valves help a lot by using less energy, costing less to care for, and staying reliable in high-pressure systems. These valves help factories run smoothly. This part looks at how they help work go well.

Help with Saving Energy

Miwival ball valves help save energy in factory systems. They cause very little pressure drop when fully open. This cuts the energy needed to push liquids through pipes. This point is very helpful in big jobs where energy bills make up a large part of running costs.

The smooth inside of these valves cuts down on swirling and rubbing during liquid moving. This neat design not only saves power but also helps other machines last longer by easing strain.

Part in Lowering Care Costs

The strong design and good stuff used in Miwival ball valves mean lower care costs over time. These valves are made to face hard working spots without needing lots of fixes or new parts. Also, their simple build makes checking and fixing easy when needed.

By cutting down on surprise stops from valve breaks or leaks, Miwival ball valves make work more reliable. This drop in care work lets factories use their people and money better in other key spots.

Work in High-Pressure Systems

In high-pressure systems, Miwival ball valves still work best. They can handle pressures up to many thousand psi without losing power or safety. The well-made seals stay strong even when pressure jumps around a lot.

Factories dealing with squeezed gases or liquids gain much from these valves’ trustworthiness. Their power to keep working the same under hard times makes sure factory jobs run smooth without stops from broken tools.

Why Do Many Different Fields Choose Miwival Ball Valves?

Miwival ball valves can change to fit the special needs of many fields, like oil and gas, chemical work, and water cleaning. Their ability to fit different work spots shows why they matter in today’s factory uses. Below, we see what they do in key areas.

Use in Oil and Gas Work

In oil and gas jobs, safety and working well are top needs. Miwival ball valves play a key part here. They are used a lot in finding oil and gas, and later in making them ready for use. They control the flow of crude oil, natural gas, and made products.

Role in Chemical Making Plants

Chemical plants need tools that can face strong chemicals while keeping exact control over liquid systems. Miwival ball valves meet these needs easily because of their rust-fighting stuff and solid seals.

They can handle both high heat and high pressure. This makes them key for controlling chemical changes inside reactors or managing pipes that carry risky stuff. Being easy to make automatic helps even more for tricky control systems in this field.

Value in Water Cleaning Buildings

Water cleaning places need good flow control for steps like filtering, adding chlorine, and sending out clean water. Miwival ball valves work great by ensuring no leaks in all parts of water cleaning.

They work with drinking water rules. This makes them right for city water systems and factory waste water jobs. What’s more, their low-care design helps cut running costs. It also makes sure they follow nature rules about water quality systems.

What Makes Miwival a Trusted Ball Valve Maker?

Miwival’s name as a good valve maker comes from sticking to quality, always making new things, and solving problems for buyers. By following strict making rules and using new tech, the company promises top product work. This part shows what makes Miwival different in a busy market.

Promise to Quality Rules

Miwival is a top ball valve maker by following tough quality rules. The company uses top stuff like stainless steel, brass, and other rust-fighting metals when making things. These materials help the valves face hard factory spots while working well for a long time.

The making way includes careful checks at every step, from picking stuff to putting it together. This close look means each valve meets or beats field marks for strength, trust, and safety. Also, Miwival’s items follow world rules and stamps. This makes them even more trusted as a good maker.

New Ideas and Tech Steps

Miwival always puts money into research to lead in the busy factory uses market. Using the newest tech, the company has added fresh parts to its ball valves. These make them work better and save more. For example, adding spark-stopping parts and fire-safe builds keeps things safe in key jobs with stuff that can burn or harm.

Making things automatic is another place where Miwival shines. Adding smart tech lets workers watch and control valves from far away. Factories can then make their work better with less need for people. These steps not only help work go better but also save money by using less power and needing less care.

Also, Miwival’s care for the planet has led to earth-friendly answers that hurt nature less. The neat shape of their valves cuts energy loss when moving liquids. This makes them a smart pick for factories wanting greener work.

Focus on Buyers and World Reach

Miwival’s buyer-first thinking sets it apart. The company really tries to know the special needs of its buyers in many fields. This way, they can offer made answers that fix specific problems buyers face.

With a strong world sales net, Miwival gets items to buyers everywhere on time. Their promise to help after buying builds more trust. Whether it’s tech help or spare parts ready, Miwival does extra to make buyers happy.

Also, the company’s power to fit different market needs makes it a liked partner for firms working in many places. By giving choices to change things and bendy service ways, Miwival serves a wide range of factory uses with great accuracy and trust.

Conclusion

Miwival’s care for quality, new ideas, and buyer joy show why it’s a trusted ball valve maker for factory uses. The company’s promise to be the best is clear in all it does, from item design and making to help after buying.

FAQs About Miwival Ball Valves

What Stuff Makes Miwival Ball Valves?

Miwival uses strong stuff like stainless steel, brass, and other rust-fighting metals to build its ball valves. These things are picked because they can take very hot or cold temps, high pressure, and corrosive spots common in factory jobs.

Using new sealing ideas makes these valves stronger and more reliable. By putting in top tech during making, Miwival makes sure its items work the same even under hard times.

Can Miwival Ball Valves Take Very Hot or Cold Temps?

Yes, Miwival ball valves are made to work well across a wide span of temps. Their tough build lets them work right in very hot spots like chemical plants and very cold spots like freezing systems.

The well-made parts stay sound under heat stress. This keeps work going when temps change fast. This power makes Miwival ball valves fit for hard factory jobs where hot or cold extremes matter a lot.

Can You Change Them for Special Field Needs?

Miwival gives many ways to change things for special needs. Buyers can pick from different stuff, sizes, pressure levels, and connection types based on how they work.

The company also offers made answers for special uses like automatic systems or unique flow problems. By talking closely with buyers during planning, Miwival makes sure its changed items fit field needs perfectly while keeping high quality and work.