Flow Control Gate Valve vs. Ball Valve: Which One Fits Your Application?

In industrial flow systems, picking the proper valve for your needs is vital for efficiency, safety, and lasting operation. These devices form the essential framework for managing liquids and gases in sectors like pulp and paper, mining, chemical plants, and sewage facilities. Among numerous choices, Flow Control Gate Valves and Ball Valves are notable for their adaptability and dependability. However, deciding between them demands a thorough grasp of their construction, working principles, and appropriateness for particular situations. This piece compares Flow Control Gate Valves and Ball Valves to help you select wisely for your operational demands.

Understanding Flow Control Gate Valves

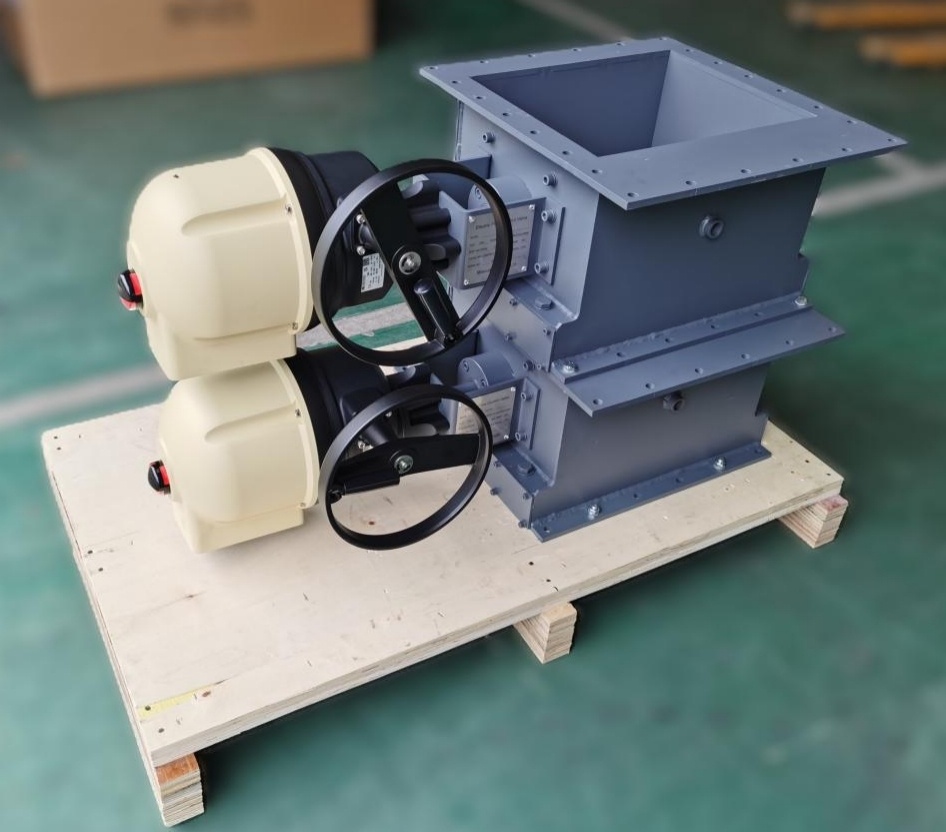

What is a Flow Control Gate Valve?

A Flow Control Gate Valve is a specialized device made to adjust the movement of loose substances, such as cement, lime, gypsum, or ash. These typically operate at the outlet of storage containers. Unlike basic gate valves used mainly for start/stop tasks, Flow Control Gate Valves are crafted for exact movement management. They deliver outstanding accuracy and consistent outcomes. These devices are frequently employed in fields like cement manufacturing, mining, and handling loose substances.

Key Features of Flow Control Gate Valves

These units handle demanding environments well, especially those involving rough particles and thick mixtures. Their important characteristics include:

- Exceptional Accuracy:Fitted with pneumatic turning actuators and positioners, these units provide superb precision in managing the movement of powdered loose goods.

- Sturdy Construction:For instance, the Miwival Flow Control Gate supports moving capacities reaching 1000 m³/h. This makes it fit for heavy industrial uses.

- Longevity:Parts are engineered to resist damage. Replaceable sections extend their working lifespan.

- Two-Way Sealing:Designs like the MDU and MGA/MGD knife gate valves offer sealing in both directions. This is perfect for managing rough slurries in mining and sewage treatment.

Applications of Flow Control Gate Valves

These devices are broadly used in sectors needing exact handling of loose substances. Frequent uses involve:

- Cement Sector:Controlling the movement of base elements like limestone in cement production lines.

- Mining:Overseeing rough slurries in mineral handling and extraction.

- Pulp and Paper:Managing thick mixtures in recycling processes.

- Sewage Treatment:Adjusting movement in sludge handling setups.

Understanding Ball Valves

What is a Ball Valve?

A Ball Valve is a quarter-turn device using a round ball with an opening to manage the movement of liquids or gases. When functioning, the hole lines up with the path, permitting free passage. When shut, the ball turns to obstruct movement, creating a completely leak-proof closure. Ball Valves are recognized for their straightforwardness, trustworthiness, and minimal upkeep demands.

Key Features of Ball Valves

Miwival’s Ball Valves are built for toughness and performance under hard conditions. Their essential traits include:

- Absolute Leak Prevention:Guarantees zero leakage. This makes them perfect for vital situations.

- Low Operation Force:Trunnion-mounted constructions and live-loaded packing decrease force needs. This permits using smaller actuators.

- Fire-Resistant Choices:Obtainable with graphite stem seals meeting API 607 standards for fire-safe scenarios.

- Adaptability:Appropriate for both start/stop and gradual control tasks. Options include floating and trunnion-mounted constructions.

Applications of Ball Valves

Ball Valves are highly adaptable and utilized across many sectors, including:

- Chemical Handling:Managing corrosive substances with materials like stainless steel.

- Oil and Gas:Overseeing high-pressure gas and liquid movement in pipelines.

- Food and Drink:Giving hygienic closure in food-grade situations with BUNA-N or EPDM seats.

- Power Production:Managing steam and water movement in electricity plants.

Comparing Flow Control Gate Valves and Ball Valves

To identify which device fits your situation, comparing their performance across vital criteria is key. The following table shows differences between Flow Control Gate Valves and Ball Valves:

|

Criteria |

Flow Control Gate Valve |

Ball Valve |

|

Primary Function |

Exact movement adjustment of loose substances |

Start/stop or gradual control of liquids/gases |

|

Operation |

Straight-line movement, often with pneumatic actuators |

Quarter-turn function, manual or automatic |

|

Sealing |

Two-way closure, fit for slurries |

Complete leak-proof sealing, perfect for clean liquids/gases |

|

Applications |

Cement, mining, pulp & paper, sewage |

Oil & gas, chemical, food & drink, power |

|

Maintenance |

Replaceable parts for rough situations |

Minimal upkeep because of straightforward construction |

|

Pressure Handling |

Up to 16 bar (DN50-DN200) for MDU types |

Appropriate for high-pressure scenarios (Class 150-2500) |

|

Substance Suitability |

Manages rough slurries and solids |

Best for clean or slightly corrosive liquids |

When to Select a Flow Control Gate Valve

This device is the proper choice if you need to manage the movement of loose substances or rough slurries. Its tough construction and exact control make it perfect for fields like cement making and mining. Handling thick mixtures is common there. For example, Miwival’s MDT Double Gate Knife Gate Valve is made for pulp and paper situations. It offers half the cycle time of standard units. This boosts efficiency in high-frequency tasks.

When to Select a Ball Valve

This device is the proper choice if you need trustworthy closure or gradual control in clean or slightly corrosive liquid systems. Their fast quarter-turn function and complete leak-proof sealing make them suitable for situations in oil and gas, chemical handling, and food sectors. Miwival’s trunnion-mounted Ball Valves, for example, are made for high-pressure situations. They offer low force and fire-safe choices for vital tasks.

Factors to Evaluate When Picking the Correct Device

Choosing the proper device for your situation involves examining several elements:

- Substance Nature:If your situation involves rough slurries or loose solids, a Flow Control Gate Valve is probably better. For clean liquids or gases, a Ball Valve is more appropriate.

- Pressure and Heat:Ball Valves withstand higher pressures (to Class 2500) and a wider heat span. Flow Control Gate Valves are usually limited to lower pressures (to 16 bar).

- Control Demands:For exact movement adjustment, Flow Control Gate Valves perform best, especially in loose substance management. Ball Valves are better for quick start/stop or gradual control tasks.

- Upkeep Requirements:Both devices are made for minimal upkeep. However, Flow Control Gate Valves often have replaceable parts to handle damage in rough situations.

- Sector Standards:Confirm the device meets relevant standards, like API 607 for fire safety (Ball Valves) or EN1092 for flange links (Flow Control Gate Valves).

Miwival: Your Reliable Flow Control Gate Valve Provider

Miwival is a worldwide leader in valve and automation answers. It has a solid standing for delivering top-grade Flow Control Gate Valves and other industrial units. Established in 2015 by a group of skilled valve engineers, Miwival runs modern production sites in Zhejiang and Anhui, China. It operates globally across six continents. Their dedication to excellence is clear in their ISO 9001-certified methods. These include thorough material checks, non-destructive testing (NDT), and pressure checks. Miwival’s Flow Control Gate Valves, such as the MDU and MDT types, are made for toughness and precision. This makes them a trusted choice for sectors like mining, cement, and pulp and paper. Concentrating on excellence, cost, delivery, and support, Miwival ensures every device meets the particular demands of its clients.

Conclusion

Deciding between a Flow Control Gate Valve and a Ball Valve depends on your situation’s exact needs. Flow Control Gate Valves are perfect for managing loose substances and rough slurries in sectors like cement and mining. They provide precision and toughness. Ball Valves, conversely, shine in situations needing trustworthy closure and gradual control for clean liquids or gases. This makes them essential in oil and gas, chemical, and food fields. By knowing your substance nature, pressure, heat, and control demands, you can pick the proper device for your situation. Miwival’s wide selection of units and automation answers guarantees you get high-performing goods customized to your sector’s requirements.

FAQs

1. What is the core difference between a Flow Control Gate Valve and a Ball Valve?

A Flow Control Gate Valve adjusts loose substances precisely using straight-line movement. A Ball Valve employs a quarter-turn action for quick start/stop or gradual control of liquids and gases. It provides complete leak-proof sealing.

2. Which device is better for rough slurries?

A Flow Control Gate Valve, like Miwival’s MDU or MDT types, is the correct choice for rough slurries. Its two-way closure and replaceable parts handle thick mixtures well. This suits mining and sewage treatment fields.

3. Can Ball Valves function in high-pressure situations?

Yes. Ball Valves handle high-pressure situations well. Miwival’s trunnion-mounted constructions support pressures to Class 2500. They are perfect for oil and gas, chemical, and power production fields.

4. How do I choose the proper device for my situation?

To pick the proper device, consider the substance nature (rough or clean), pressure and heat needs, control demands (adjustment or closure), and sector standards. Talking with a reliable provider like Miwival helps guarantee the best choice.

5. Are Miwival’s Flow Control Gate Valves appropriate for the cement sector?

Completely. Miwival’s Flow Control Gate Valves are engineered for exact movement control of loose substances like cement. Types like the MDU offer two-way closure and high toughness for cement production lines.