Globe Valve vs. Gate Valve: Key Differences and When to Use Each

Valves quietly manage the flow of liquids, gases, and slurries inside complex industrial systems. They’re essential but often overlooked. Whether you operate a refinery, a water treatment plant, or a chemical processing unit, picking the right valve matters hugely. It can determine your system’s success. Globe valves and gate valves come up together often. They look somewhat alike and sometimes get used for similar jobs. But don’t let appearances trick you. These valves serve very distinct purposes. This guide explains their core differences. We’ll explore their unique strengths. We’ll help you decide which valve fits your specific needs. Let’s dive in.

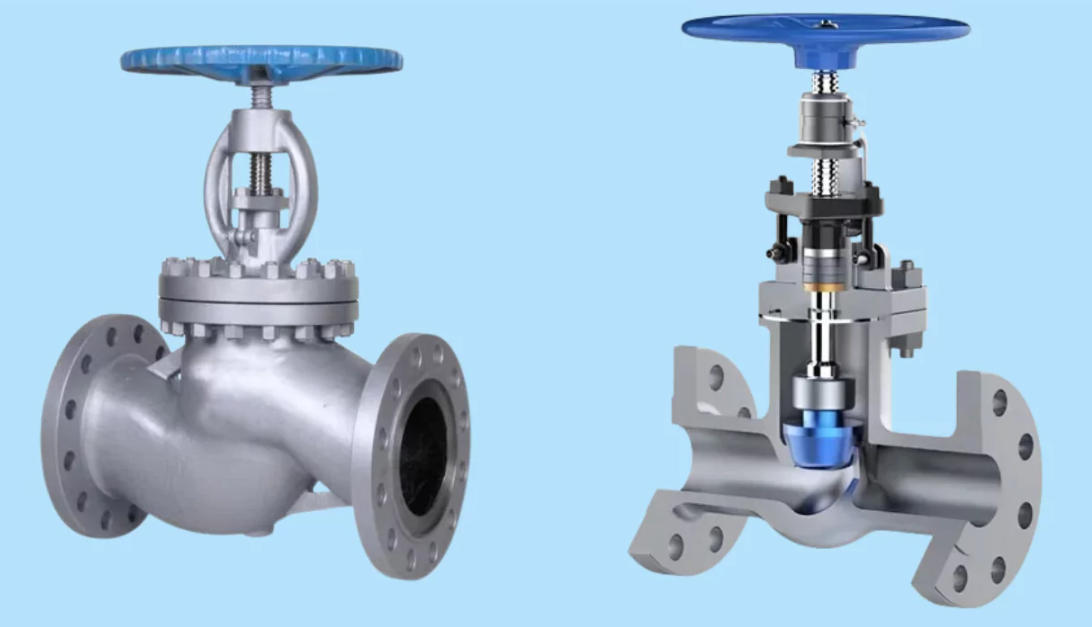

What Are Globe Valves?

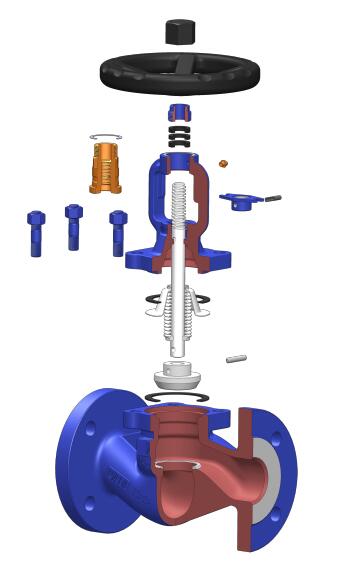

Imagine a valve shaped roughly like a globe. That’s where its name comes from. Globe valves belong to the linear motion valve family. They’re engineered for fine-tuned flow regulation. Choose them when you need to start, stop, or carefully adjust media flow. Think steam, water, or oil. Inside, the seat sits parallel to the flow path. This clever design ensures a dependable seal. It also helps minimize wear over time. Globe valves become a strong choice where leaks absolutely cannot happen.

These valves perform exceptionally well under high pressure or intense heat. They manage thick, gooey media effectively. Think slurries or heavy oils. That capability makes them popular in power plants, pulp and paper mills, and petrochemical facilities. However, this precision control has a trade-off. Globe valves typically cause a larger pressure drop than some other valve types. This can impact your system’s overall efficiency. You need to account for it during design.

Key Features of Globe Valves

- Throttling Capability:Superb for adjusting flow with accuracy.

- Tight Sealing:The internal plug creates a reliable seal, cutting down leakage risks significantly.

- Durability:Constructed to endure intense heat and high-pressure conditions.

- Maintenance:Top-entry design offers simpler access to internal parts for servicing.

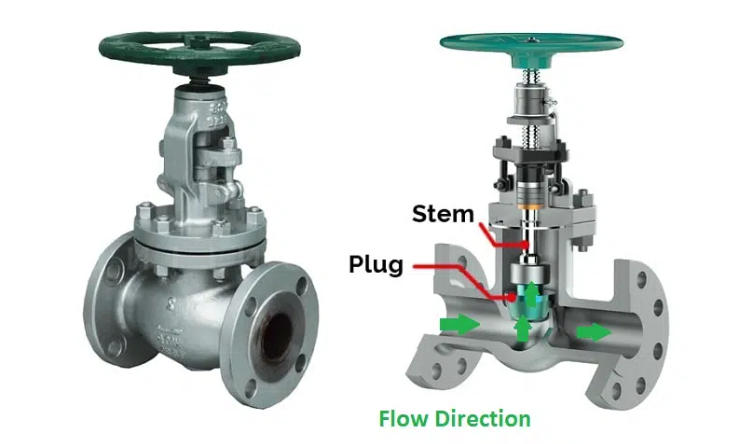

What Are Gate Valves?

Now, picture a valve acting as a literal gatekeeper. It’s either fully open or completely shut. There’s no middle ground. That’s a gate valve. They fall into the shutoff valve category. Gate valves use a wedge-shaped gate and a stem that rises (or doesn’t) to manage flow. Their job is isolation. They provide a solid seal to halt flow entirely. Unlike globe valves, throttling isn’t their purpose. They deliver an all-or-nothing solution.

Gate valves handle a remarkably wide variety of fluids. Water, gas, slurries – they manage them all. You see them everywhere in pipelines, refineries, and municipal water systems. A special version, the knife gate valve, works particularly well with thick, viscous substances. Gate valves also tend to be kinder on your budget compared to globe valves. This makes them a frequent choice for projects watching costs closely.

Key Features of Gate Valves

- Isolation:Ideal for completely stopping flow with a dependable seal.

- Bidirectional Flow:Handles media moving in either direction effectively.

- Low Pressure Drop:Offers minimal flow resistance when wide open, preserving system energy.

- Cost-Effective:Generally less pricey than globe valves upfront.

Globe Valve vs. Gate Valve: A Head-to-Head Comparison

So, how do these two really compare? Let’s break it down clearly. We’ll highlight differences in how they work, their build, sealing ability, and best uses.

|

Aspect |

Globe Valve |

Gate Valve |

|

Functionality |

Starts, stops, and finely regulates flow. |

Isolates media by opening fully or closing fully; throttling damages them. |

|

Structure |

More complex inside with flow path changes aiding regulation. |

Simpler build; body becomes hollow when open; features rising or non-rising stem. |

|

Sealing |

Superior seal from the internal plug; excellent for leak-critical applications. |

Seal occurs on the gate surfaces; functional but slightly less bulletproof than globe valve seals. |

|

Pressure Drop |

Higher pressure drop caused by the obstructed flow path. |

Very low pressure drop when fully open, perfect for high-flow efficiency. |

|

Applications |

High-pressure, high-temperature, or viscous media (steam, chemicals). |

General-purpose isolation for fluids like water, gas, or slurries. |

|

Cost |

More expensive due to intricate design and often specialized materials. |

More budget-friendly, simpler construction keeps costs down. |

Functionality: Control vs. Isolation

Globe valves are the masters of flow control. They let you fine-tune precisely. You might adjust steam in a power station or manage chemical flow in a processing plant. Gate valves, in contrast, focus purely on isolation. Need to shut down a pipeline for repairs? A gate valve is your dependable tool. Trying to throttle flow with one is a bad idea. It’s like using a sledgehammer for a delicate nut. It’s simply the wrong instrument.

Structure: Complexity vs. Simplicity

Globe valves boast a more involved internal arrangement. Components like the seat and plug are designed to shift flow direction and create resistance. This makes them heavier and bulkier. Yet, it’s precisely why they excel at throttling. Gate valves are fundamentally simpler. A gate slides straight into or out of the flow path. When open, the valve body is essentially empty inside. This explains their efficiency in high-flow situations.

Sealing: Tight vs. Functional

For sealing power, globe valves generally win. Their internal plug creates a very strong, dependable seal. This makes them ideal where even a tiny leak spells big trouble. Imagine a chemical plant handling dangerous fluids. Gate valves seal on the gate’s surface. This works well enough for most shutoff jobs. But it doesn’t quite match the globe valve’s sealing confidence for critical applications.

Applications: Specialized vs. General

Reach for globe valves when specialized performance is essential. Consider high-pressure steam systems in power generation. Think about moving viscous slurries in pulp mills. They handle demanding conditions reliably. Gate valves, meanwhile, are the versatile workhorses. They suit countless general-purpose jobs. They’re perfect for water distribution networks. They excel in oil and gas pipelines. Pick them anytime you need absolute flow stoppage without worrying much about pressure loss.

When to Use a Globe Valve

Choose a globe valve when precision and long-term toughness are mandatory. Here are scenarios where they prove invaluable:

- Water treatment: Used in urban water supply systems as shut-off or flow regulation valves. Note: Not suitable for sewage sections containing large amounts of sludge and impurities.

- Heating and Air Conditioning Systems: In centralized heating pipelines and central air conditioning water circulation systems, they are used to regulate water and control indoor temperature. Their excellent sealing performance can prevent the leakage, thereby avoiding energy loss.

- Petroleum and Energy Industry: Used for cutting and regulating the flow of crude oil, refined oil, liquefied petroleum gas, etc. It is not suitable for crude oil containing a large amount of sand and gums. In the power industry, theycan be used in steam, condensate water pipelines, and cooling water systems to control the flow.

- Chemical Production: In pipelines transporting clean chemical media such as acidic or alkaline solutions (such as dilute sulfuric acid, caustic soda solution), or organic solvents, it is used as a shut-off or flow regulation valve. (Note: The valves should be made of corrosion-resistant materials such as stainless steel.)

- Pharmaceutical Industry: For the piping systems of purified water, injection water, medicinal solutions, etc., it must comply with GMP standards. The material should be corrosion-resistant and easy to clean. The excellent sealing performance of the stop valve can prevent external contaminated media.

- Light Industry: In the hot water and dyeing solution (a liquid without a large amount of fiber impurities) pipelines of the dyeing and finishing process, it is used to regulate the flow rate and temperature.

- Metallurgical Industry: In the auxiliary system pipelines such as cooling water and hydraulic oil, it is used as a shut-off or low-flow regulating valve (not suitable for directly used in media containing slag and iron filings).

- Ships and Marine Engineering: In the power systems of ships (such as fuel pipelines, steam pipelines), ballast water systems, and fresh water systems, stop valves are often used for cutting off and controlling various liquid and gas media due to their compact structure and good vibration resistance.

For instance, engineers at a Southeast Asian pulp mill recently chose globe valves. They needed to control slurry flow inside a high-pressure digester setup. The valves’ precise throttling ability was key. Their resistance to corrosion from the harsh slurry was vital. This choice prevented expensive operational halts.

Miwival: Your Trusted Globe Valve Supplier

For sourcing top-quality globe valves, Miwival stands as a reliable partner. They bring over ten years of deep valve engineering knowledge. Miwival specializes in designing and making globe control valves. These valves deliver accuracy, long life, and safety. They serve industries like power generation, chemical processing, and pulp and paper. Miwival operates from modern facilities in Zhejiang, China. Their global footprint is growing and their products have already reached most parts of the world. This ensures speedy delivery and tailored support. Their modular valve designs feature easy-maintenance clamping seat systems. These designs meet the tough demands of high-pressure and high-heat uses. Engineers worldwide turn to Miwival as a go-to source.

Conclusion

Picking between a globe valve and a gate valve hinges entirely on your specific requirement. Need precise flow control in a demanding setting? A globe valve’s strong sealing and regulation power justify its cost. Need a cost-efficient, dependable way to isolate media? A gate valve’s simplicity and low pressure loss make it the clear choice. Grasping the key differences – how they function, their build, sealing quality, and best uses – is crucial. This knowledge lets you decide wisely. It keeps your system operating smoothly. Whether you manage a refinery, a water plant, or a chemical factory, choosing the correct valve is a small decision with major consequences.

FAQs

What’s the main difference between a globe valve and a gate valve?

Their core purpose differs completely. Globe valves are built for accurate flow adjustment. They let you start, stop, or throttle media like steam or chemicals carefully. Gate valves exist for isolation. They stop flow entirely with a secure seal. Regulating flow isn’t their job.

Can I use a gate valve instead of a globe valve for throttling?

Avoid doing this. Gate valves aren’t built for throttling. Trying to regulate flow with them causes wear. The gate erodes. This leads to leaks eventually. Globe valves, with their internal design, are the proper choice for throttling tasks.

When should I choose a globe valve over a gate valve?

Opt for a globe valve when you require exact flow control under high pressure or intense heat. Chemical processing or steam systems are classic examples. They’re ideal where preventing leaks and resisting corrosion are top priorities.

Are gate valves more cost-effective than globe valves?

Generally, yes. Gate valves usually cost less upfront. Their simpler design is the reason. They’re a smart pick where isolation is the main goal, and budget matters. Water or gas pipelines are typical uses.

How do I maintain a globe valve vs. a gate valve?

Globe valves often feature a top-entry design. This simplifies upkeep. You access internal parts without taking the whole valve out of the pipe. Gate valves might need more effort to service. Their simpler build can sometimes mean less easy access. Regular check-ups for both types ensure they last reliably.