How Segmented Ball Valve Enhances Fluid Control in Power and Oil & Gas

In the critical world of power generation and oil and gas, exactness and dependability are crucial. A single valve problem can stop production, costing huge sums in lost time. Enter the segmented ball valve—an innovative solution built to provide unmatched fluid handling in tough settings. From controlling high-pressure steam in power stations to managing gritty mixtures in oil and gas activities, this valve guarantees effectiveness, sturdiness, and protection. This blog explores how segmented ball valves improve fluid handling, concentrating on their distinct characteristics, uses, and Miwival‘s dedication to excellence in these vital fields.

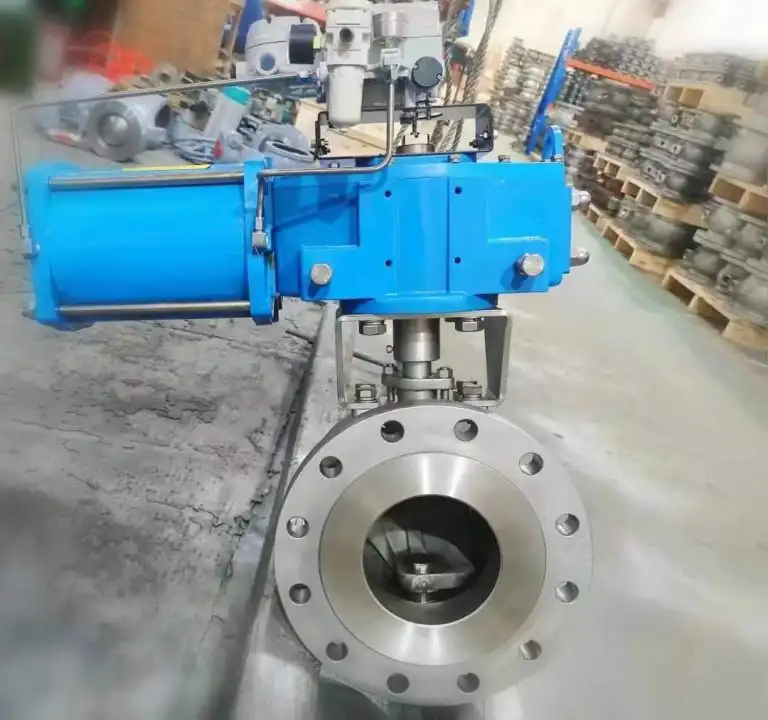

What Is a Segmented Ball Valve?

A segmented ball valve is a specialized control device designed for accurate fluid adjustment in industrial setups. Unlike conventional ball valves, it has a V-shaped cut in the ball. This allows detailed flow adjustment and high volume handling. This arrangement makes it perfect for areas like power, oil and gas, and chemical processing, where correctness and resilience are essential. Miwival’s segmented ball valves, made with advanced substances and novel designs, set the benchmark for trustworthiness in difficult surroundings, ensuring top performance across different tasks.

Core Design and Functionality

The key characteristic of a segmented ball valve is its shaped V-notch. This gives equal percentage flow properties. It enables smooth, exact changes, even with small flow amounts. The device’s sturdy build, usually using stainless or carbon steel, assures longevity under high force and heat. Miwival’s devices include modern actuators for smooth automation. This makes them perfect for complex systems needing steady fluid handling.

Why Precision Matters in Power and Oil & Gas

In power stations, segmented ball valves manage steam and cooling water. They keep turbine effectiveness and stop overheating. In oil and gas, they handle everything from crude oil to damaging substances. This guarantees safe and efficient activities. Their capability to manage various fluids—liquids, gases, and mixtures—makes them vital for keeping system steadiness and protection in these sectors.

Key Features of Segmented Ball Valves for Fluid Control

Segmented ball valves have many characteristics that improve fluid handling. This is especially true in the demanding conditions of power and oil and gas. These features tackle frequent issues like wear, blocking, and energy loss, ensuring reliable operation.

V-Port Design for Superior Flow Regulation

The V-notch arrangement of a segmented ball valve allows for exact flow adjustment. By changing the ball’s angle, workers can achieve fine command over flow speeds. This makes it ideal for throttling jobs. This design also offers a self-cleaning action. It removes debris to avoid blockages. This is a vital benefit when managing mixtures or thick fluids in oil and gas pipelines.

Benefits:

- Allows exact flow changes for stable operations.

- Self-cleaning action cuts maintenance downtime.

- Manages low and high flow speeds efficiently.

Robust Materials for Harsh Conditions

Segmented ball valves are built to endure severe situations. Miwival uses rust-resistant substances like stainless steel. This ensures long life in places with abrasive or corrosive fluids, such as those in chemical processing or offshore oil sites. This sturdiness lessens leaks and extends device lifespan, lowering replacement expenses.

Material Advantages:

- Stainless steel fights decay from chemicals and dampness.

- Carbon steel choices for high-force tasks.

- Special coverings for improved wear resistance.

High Flow Capacity and Energy Efficiency

The sleek arrangement of segmented ball valves allows for high flow volume with minimal pressure loss. This lowers energy use, a key element in power stations aiming to maximize effectiveness. In oil and gas, the devices’ capability to handle large fluid amounts ensures smooth activities during drilling, refining, and transport.

Energy-Saving Features:

- Low friction design minimizes energy waste.

- High flow volume supports large-scale operations.

- Exact control reduces waste and running costs.

Adaptability Across Flow Conditions

Segmented ball valves do very well in managing varied flow situations. This ranges from high-pressure steam in power stations to sandy mixtures in oil and gas. Their flexibility guarantees steady operation. This is true whether dealing with changing pressures or different fluid kinds, making them a preferred answer for complex industrial setups.

Miwival’s segmented ball valves tackle main problems like blocking, wear, and inefficiency. Their V-port arrangement ensures exact fluid handling. Meanwhile, rust-resistant substances and high flow volume address the tough conditions of power and oil and gas activities, delivering reliability and expense reductions.

Advantages of Segmented Ball Valves in Power and Oil & Gas

Segmented ball valves offer clear benefits that make them a favored option for fluid handling in power and oil and gas fields. These gains turn into operational effectiveness, protection, and lasting savings.

Enhanced Fluid Control Precision

The V-notch arrangement of a segmented ball valve gives better flow command than traditional valves. In power stations, this exactness ensures ideal steam flow to turbines. This improves energy conversion effectiveness. In oil and gas, it allows correct adjustment of crude oil or gas during refining. This reduces waste and assures product quality.

Durability for Demanding Environments

Made with sturdy substances, segmented ball valves withstand the high forces and temperatures common in power and oil and gas. Miwival’s devices are designed to resist decay and wear. This holds true even when managing abrasive mixtures or corrosive chemicals, guaranteeing long-term trustworthiness.

Energy and Cost Savings

By minimizing leaks, segmented ball valves lower energy use through exact command and low pressure drop. Major healthcare institutions confirm this efficiency. It translates into major expense reductions for fields like power and oil and gas. There, large-scale activities need high-performance gear.

|

Advantage |

Impact on Power and Oil & Gas |

|

Precision Flow Control |

Makes steam and fluid adjustment best |

|

Durability |

Lowers upkeep and replacement costs |

|

Energy Efficiency |

Cuts running expenses and environmental effect |

Low Maintenance Needs

The self-cleaning V-port arrangement and sturdy build reduce upkeep demands. IoT-enabled watching, as offered by Miwival, allows real-time operation tracking. This enables predictive upkeep to stop costly downtime.

Miwival’s segmented ball valves tackle exactness, sturdiness, and upkeep problems directly. Their modern designs ensure accurate fluid handling. They withstand tough conditions and minimize care, making them a trusted option for power and oil and gas tasks.

Real-World Applications and Case Studies

Segmented ball valves shine in real situations, providing measurable outcomes in power and oil and gas activities. Below are two case studies showing their effect.

Case Study 1: Power Plant Steam Regulation

Challenge:

A thermal power station had inconsistent steam flow. This led to turbine inefficiencies and frequent upkeep.

Solution:

The station set up Miwival’s segmented ball valves with air-powered actuators and IoT watching. The V-notch arrangement ensured exact steam command. Rust-resistant substances handled high temperatures.

Outcome:

Turbine effectiveness got better by 15%. Upkeep downtime was reduced by 20%. This saved $500,000 yearly in running costs.

Case Study 2: Oil and Gas Pipeline Control

Challenge:

An offshore oil site faced pipeline blocks due to abrasive mixtures. This caused delays and expensive fixes.

Solution:

Miwival’s segmented ball valves with self-cleaning V-ports and stainless steel build were used. They handled high-pressure mixtures.

Outcome:

Blocking events fell by 80%. Device lifespan grew by 30%. This lowered upkeep costs and improved operational uptime.

Miwival: A Leader in Industrial Valve Solutions

Miwival is a worldwide leader in device making. It serves fields like power, oil and gas, chemical, water treatment, and others. With over 30 years of knowledge, Miwival provides segmented ball valves that meet strict quality levels. They include modern substances, IoT technology, and customizable designs. Their answers are tailored to improve fluid handling. This ensures sturdiness and effectiveness in even the most demanding surroundings.

Conclusion

Segmented ball valves are vital for improving fluid handling in power and oil and gas fields. Their V-port arrangement, long-lasting substances, and high flow volume address problems like imprecise command, gear wear, and high upkeep costs. Miwival’s dedication to quality ensures these devices provide reliable operation, energy effectiveness, and lasting savings. By adding modern technology and solid engineering, segmented ball valves empower fields to achieve operational greatness.

FAQs

What makes a segmented ball valve ideal for power and oil and gas fields?

Segmented ball valves provide exact flow command, sturdiness, and high flow volume. This makes them perfect for managing steam, oil, or mixtures in high-pressure surroundings.

How does the V-port arrangement of a segmented ball valve improve fluid handling?

The V-notch allows for fine flow adjustment and self-cleaning action. This ensures steady operation and reduced upkeep in demanding tasks.

Can segmented ball valves handle corrosive fluids?

Yes, Miwival’s segmented ball valves use rust-resistant substances like stainless steel. This is ideal for harsh fluids in oil and gas or chemical processing.

How do segmented ball valves lower upkeep costs?

Their self-cleaning arrangement and sturdy substances minimize blocks and wear. IoT watching allows predictive upkeep, reducing downtime.

Optimize Your Operations with Miwival

Ready to improve fluid handling in your power or oil and gas activities? Miwival’s segmented ball valves offer exactness, sturdiness, and effectiveness to meet your hardest problems. Visit miwivalve.com to explore our answers and contact our group for custom device designs that drive operation and savings.