How to Maximize Lifespan of Your Globe Control Valve

What Are Some Common Issues That Shorten Globe Valve Life?

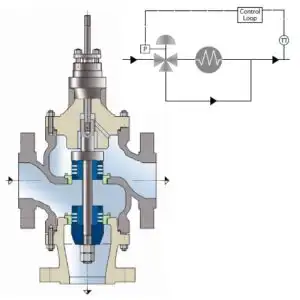

These valves regularly encounter problems like cavitation, corrosion, and erosion. These problems weaken functioning slowly. Spotting early signals and using protective plans can help lessen these issues before they cause expensive breakdowns.

Cavitation, Corrosion, and Erosion Challenges

Globe control valves are often in tough working settings that cause cavitation, corrosion, and erosion. Cavitation happens when vapor bubbles appear and burst inside the valve because of pressure changes. This causes small holes on inner parts. Corrosion comes from chemical reactions between the valve parts and the flowing substance, particularly in harsh surroundings like acidic or salty liquids. Erosion is caused by fast-moving flow carrying rough bits that grind down the valve inside over time.

Identifying Early Warning Signs

Finding valve damage early is vital. Sounds like hissing or popping might mean cavitation. Color change on surfaces, flaking, or rust show corrosion. A drop in how well it works or leaking could point to erosion harm. Watching for these clues allows for preventive upkeep before total failure.

Preventative Measures to Minimize Damage

Choosing suitable materials for the valve body and trim, adding anti-cavitation trims, and keeping ideal flow speeds can greatly lower these problems. Selecting globe valves that fit your operational needs and specifications is essential.

Miwival helps lessen these difficulties by providing different globe control valves built using corrosion-resistant alloys and designed for accurate throttling uses.

What Factors Affect the Longevity of a Globe Control Valve?

Valve sturdiness relies on material suitability, working settings, and substance traits. Picking the correct building materials and grasping system behavior are important for getting the longest service life.

Material Selection and Its Impact on Durability

The choice of building material directly changes resistance to wear, corrosion, and temperature extremes. Using carbon steel, stainless steel and other different main materials can be suitable for various media. For example, stainless steel gives excellent corrosion resistance for chemical handling uses.

The Role of Operating Conditions in Wear and Tear

Big pressure drops, very hot or cold temperatures, and constant use speed up mechanical tiredness. Bellows sealed globe valves are suitable for pipelines under various working conditions in petroleum, chemical, pharmaceutical, fertilizer, electric power, and other industries. Understanding your system’s behavior is necessary to pick a globe valve rated for those conditions.

Influence of Media Type on Valve Performance

Abrasive mixtures or chemically reactive liquids need special sealing systems and inner coatings. Unsuitable substances can break down seals or wear away inner parts quickly.

Miwival handles these issues with a wide product selection including bellows sealed globe valves made for harsh substances across many fields.

How Can Proper Installation Extend Valve Service Life?

Right sizing, alignment, and fixing methods are vital for best valve performance. Avoiding frequent setup errors guarantees smooth action and lowers long-term damage.

Importance of Correct Sizing and Alignment

Wrong sizing leads to poor throttling or too much pressure loss. Poor alignment during setup causes stem sticking or uneven seat wear. Your globe valve, being unidirectional, holds a crucial role in controlling the flow of the commodity.

Best Practices for Mounting and Piping Connections

Ensure proper support for pipes to avoid extra stress on the valve body. Use matching flange faces and gaskets to stop leaks. Stick to torque specs during bolting to keep seal soundness.

Avoiding Common Installation Mistakes

Do not put in against flow direction unless specifically made for two-way use. Avoid over-tightening packing glands which may harm the stem.

Miwival stresses setup exactness by giving clear instructions matching API 602 and ASME B16.34 rules to ensure top performance from the start.

What Maintenance Practices Are Essential for Long-Term Reliability?

Regular checks, lubrication, and timely part changes are vital for keeping valve performance. A planned upkeep schedule lowers surprise failures.

Routine Inspection Schedules and Checkpoints

Regular checks help find problems before they become failures.

Visual Inspection Guidelines

Look for signs of outside leaks near bonnet joints or gland packing. Check actuator links for looseness or poor alignment.

Functional Testing Procedures

Operate the valve now and then under no-load settings to ensure smooth action without sticking or needing too much torque.

Lubrication and Cleaning Techniques

Using the correct oils and cleaning ways lowers friction and stops dirt, ensuring smooth valve action.

Recommended Lubricants for Globe Valves

Use high-heat grease good for steam service or man-made oils matching process liquids to lower stem friction.

Cleaning Protocols Based on Application

Wash systems prone to dirt often using clean water or cleaners approved for your process substance.

Replacing Worn Components Before Failure

Change seats, discs, bellows seals, or packing before clear harm hurts operation. Taking these key steps can significantly increase the life of your globe valve.

Miwival backs long-term dependability by offering spare parts access across its product line plus advice on predictive upkeep schedules.

How Do Operational Habits Influence Valve Lifespan?

Frequent opening/closing, pressure jumps, and wrong handling speed up wear. Improving flow control and teaching users can notably extend valve life.

Effects of Frequent Cycling and Pressure Spikes

Quick opening/closing tires actuators while sudden pressure jumps cause inner shock loads that damage seating surfaces too soon.

Optimizing Flow Control to Reduce Stress on Internals

Avoid working at mid-stroke points under high pressure differences unless made just for throttling work. Globe valves are widely selected for their short travel.

Training Operators for Consistent Handling

Teaching staff on proper handwheel use stops over-tightening that harms stems or seats over time.

Miwival improves action steadiness through easy-to-use designs like rising-rotating stems that give better feel during hand use.

When Should You Consider Retrofitting or Upgrading Your Globe Valve?

Ongoing leaks, harder operation, or old technology show the need for updating. Retrofitting with modern parts can improve action without full replacement.

Signs That Indicate the Need for Modernization

Ongoing leaks despite repacking, needing more force to turn, or failing to meet new process needs suggest it’s time to update parts or change old designs completely.

Benefits of Retrofitting with Advanced Components

Modern upgrades like bellows seals better control emissions while smart positioners boost automation features without full replacement costs.

Miwival provides retrofit kits fitting older systems while adding modern sealing tech from global rules compliance.

How Can Digital Monitoring Improve Maintenance Efficiency?

Smart sensors and predictive analysis allow real-time condition watching, enabling preventive upkeep and lowering unplanned stops.

Integration of Smart Sensors in Globe Valves

Sensors built into actuators can follow position, cycle numbers, heat exposure, and shaking—offering real-time condition watching abilities.

Using Data Analytics to Predict Failures

Gathered data helps guess part fatigue trends so upkeep teams can plan changes ahead of time instead of reacting—minimizing stop risk.

Miwival adds digital solutions into its control valves allowing predictive checks that fit Industry 4.0 upkeep plans.

Why Is Supplier Quality Critical to Valve Longevity?

Choosing a certified maker ensures following field rules, dependable spare parts access, and long-term help.

Evaluating Supplier Certifications and Standards Compliance

Choose makers sticking to global rules like API 602 & ASME B16.34.All are manufactured in accordance with API 602 and ASME B16.34 standards—ensuring durability under rated conditions through strict testing steps.

Importance of After-Sales Support and Spare Parts Availability

Trusted suppliers keep strong stocks of replacement parts ensuring little downtime during service while offering help after setup.

Miwival stands out through certified making steps combined with quick after-sales help tailored to user-specific needs across Class 150–2500 grades.

Who Is Miwival and Why Choose Them as Your Globe Valve Supplier?

Miwival provides a full range of top-quality globe valves, supported by modern engineering, strict following of global rules, and outstanding customer help.

Overview of Miwival’s Product Range and Capabilities

Miwival manufactures the full series of globe valves, including T type, Y type and angle type. These include choices like rising stem/rising-rotating stem designs fitting both shut-off service and throttling work. Globe Valves feature an outside stem and yoke (OS&Y), and are available in Class 150-1500 in conventional port with threaded, socketweld, buttweld or RF ends.

Commitment to Quality, Innovation, and Customer Support

It adopts international advanced technology and double sealing design. With focus on energy efficiency improvement & reduced maintenance costs,it has the characteristics of high-performance elastic metal bellows—making Miwival perfect for critical uses needing long life under severe conditions.

Conclusion

Getting the longest life from your globe control valve needs a full plan—from picking strong materials fitting specific substance types to using careful setup methods; from doing regular checks backed by digital watching tools to making sure supplier quality supported by global approvals like API 602/ASME B16.34 compliance. Miwival’s complete set backed by technical skill makes it a trusted partner in reaching long-term working dependability across many fields.

Frequently Asked Questions

What is the problem with the globe valve?

Frequent problems include cavitation harm from pressure drops; corrosion from harsh substances; wrong setup leading to stem misalignment; constant opening/closing causing actuator tiredness; lack of lubrication increasing wear; all adding to shorter service life if not fixed quickly.

What are the limitations of a globe valve?

Globe valves have bigger pressure drops compared to gate valves due to their twisted flow path; they might also need more force/turn during use especially under high-pressure settings if not fitted with proper actuators.

How can the life of a control valve be extended?

Following these simple steps can ensure the optimal performance and increased life of your globe valve. These include right sizing & alignment at setup; regular check & lubrication; changing worn parts early; picking suitable materials based on liquid traits; teaching users properly; adding smart watching systems where possible.