Plug Valve Uses and Benefits: Essential Applications Uncovered

Plug valves are a cornerstone in industrial fluid control, offering robust solutions for managing flow in various systems. Known for their simplicity, durability, and versatility, plug valves are widely used across industries like oil and gas, chemical processing, and water treatment. In this blog, we’ll explore the uses and benefits of plug valves, uncover their essential applications, and highlight why they are a preferred choice for professionals seeking reliable flow control solutions. Whether you’re an engineer, procurement specialist, or industry professional, understanding the value of plug valves can enhance your operational efficiency and system performance.

What is a Plug Valve?

A plug valve is a quarter-turn valve that uses a cylindrical or tapered plug to control the flow of fluids through a pipeline. The plug, which has one or more hollow passageways, rotates within the valve body to either allow or block fluid flow. When the valve is open, the passageway aligns with the pipeline, enabling flow; when closed, the plug rotates to block the flow path, ensuring a tight seal.

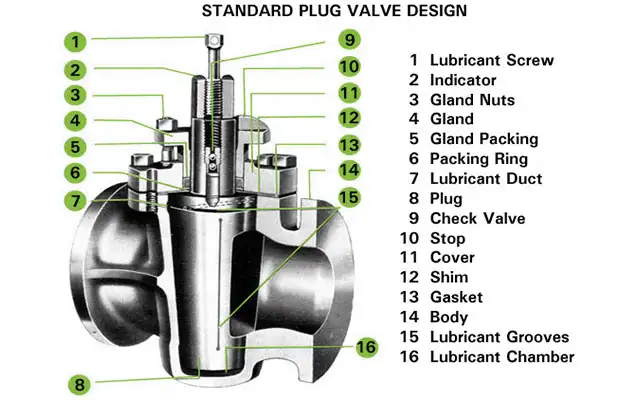

Key Components of a Plug Valve

Body: The main structure that houses the plug and connects to the pipeline.

Plug: The rotating element (cylindrical or tapered) that controls flow.

Stem/Handle: Used to rotate the plug, typically requiring only a quarter turn.

Seats: Surfaces that the plug contacts to form a seal, preventing leaks.

Plug valves are known for their simple design, which contributes to their cost-effectiveness and ease of maintenance. Their ability to provide reliable shut-off and minimal flow resistance makes them a go-to solution for many industrial applications.

Types of Plug Valves

Plug valves come in various types, each designed to meet specific operational needs. Understanding these types can help you select the right valve for your application.

Lubricated Plug Valve

Uses lubricant to reduce friction; high maintenance

Common Applications: Gas pipelines, dirty upstream applications

Non-Lubricated Plug Valve

Polymeric sleeve for low friction; low maintenance

Common Applications: Chemical processing, sulphur, hydrogen fluoride

Multi-Port Plug Valve

Multiple passageways for flow diversion

Common Applications: Transfer lines, directional flow control

Eccentric Plug Valve

Offset plug for higher seating force; low friction

Common Applications: Sewage, sludge, clean/dirty water

Expanding Plug Valve

Mechanical expansion for double block and bleed; high integrity

Common Applications: Chemical processing, contamination prevention

|

Type |

Key Features |

Common Applications |

|

Lubricated Plug Valve |

Uses lubricant to reduce friction; high maintenance |

Gas pipelines, dirty upstream applications |

|

Non-Lubricated Plug Valve |

Polymeric sleeve for low friction; low maintenance |

Chemical processing, sulphur, hydrogen fluoride |

|

Multi-Port Plug Valve |

Multiple passageways for flow diversion |

Transfer lines, directional flow control |

|

Eccentric Plug Valve |

Offset plug for higher seating force; low friction |

Sewage, sludge, clean/dirty water |

|

Expanding Plug Valve |

Mechanical expansion for double block and bleed; high integrity |

Chemical processing, contamination prevention |

Benefits of Plug Valves

Plug valves offer a range of advantages that make them a preferred choice in various industries. Below are the key benefits that highlight their value.

Simplicity and Reliability

The straightforward design of plug valves, with fewer moving parts, ensures high reliability and ease of operation. Their quarter-turn mechanism allows for quick opening and closing, reducing downtime in critical processes.

Leak-Tight Performance

Plug valves provide excellent sealing capabilities, ensuring minimal leakage even in demanding conditions. This is particularly valuable in applications requiring precise flow control or handling hazardous fluids.

Low Flow Resistance

The streamlined flow path in plug valves minimizes pressure drop, allowing for efficient fluid transport. This is a significant advantage in systems where maintaining flow efficiency is critical, such as in pipelines or high-capacity processes.

Versatility Across Applications

Plug valves can handle a wide range of fluids, including gases, liquids, and slurries, making them versatile for various industries. Their ability to operate in low-pressure, low-temperature, and even some high-pressure, high-temperature environments further enhances their utility.

Inline Maintenance

Many plug valves, particularly non-lubricated and eccentric types, support inline maintenance, reducing the need for system shutdowns. This feature lowers operational costs and improves system uptime.

Essential Applications of Plug Valves

Plug valves are employed in numerous industries due to their adaptability and robust performance. Below are some of the most critical applications where plug valves shine.

Pulp and Paper Industry

Plug valves are used for controlling the flow of pulp slurries and chemicals. Their ability to handle fluids with suspended solids makes them ideal for processes like pulp transport and chemical dosing.

Mining Operations

Plug valves are used in pumping stations, slurry transport, and dewatering processes. Their robust design ensures reliable performance in these challenging conditions.

Water and Wastewater Treatment

Plug valves manage flow during collection, separation, aeration, and discharge, making them suitable for sewage and sludge applications.

Chemical Processing

Plug valves handle corrosive fluids and high-purity requirements. Expanding plug valves with their double block and bleed function are used to prevent contamination.

Power and Energy

Plug valves are used in power generation for controlling boiler feed water, condensate, and other high-temperature fluids. Their high-capacity design and reliable shut-off capabilities make them essential for maintaining safety and efficiency in power plants.

Miwival: Your Trusted Plug Valve Supplier

Miwival is a leading provider of high-quality plug valves, offering innovative solutions tailored to meet the demands of various industries. With a commitment to quality, Miwival ensures that every valve undergoes rigorous testing, including visual inspection, chemical analysis, and pressure testing, to meet or exceed industry standards. Our range of plug valves, including the Eccentric Rotary Plug Control Valve and Ceramic Lined Eccentric Rotary Plug Control Valve, is designed for durability, precision, and performance in challenging applications. Partnering with Miwival means accessing cutting-edge valve technology backed by exceptional service and global reach.

Conclusion

Plug valves are indispensable in industrial fluid control, offering simplicity, reliability, and versatility across a wide range of applications. From handling slurries in mining to ensuring leak-tight performance in chemical processing, plug valves deliver consistent results in demanding environments. Their benefits, including low maintenance, efficient flow, and robust sealing, make them a valuable asset for engineers and operators. By choosing high-quality plug valves from trusted suppliers like Miwival, you can enhance your operational efficiency and ensure long-term system reliability.

FAQs

What is a plug valve, and how does it work?

A plug valve is a quarter-turn valve that uses a rotating plug to control fluid flow. The plug, which has a hollow passageway, rotates within the valve body to align with or block the flow path, providing a reliable shut-off or flow diversion.

What are the main benefits of using a plug valve?

Plug valves offer simplicity, leak-tight performance, low flow resistance, and versatility. They are easy to maintain, operate efficiently in various conditions, and can handle gases, liquids, and slurries, making them ideal for industries like mining and chemical processing.

Where are plug valves commonly used?

Plug valves are widely used in industries such as pulp and paper, mining, water and wastewater treatment, chemical processing, and power generation. They excel in applications involving slurries, corrosive fluids, and high-temperature flows.

How do lubricated and non-lubricated plug valves differ?

Lubricated plug valves use a lubricant to reduce friction and maintain a seal, requiring regular maintenance. Non-lubricated plug valves use a polymeric sleeve to minimize friction, making them suitable for applications where low maintenance is critical.

Why choose Miwival for plug valves?

Miwival provides high-quality plug valves designed for durability and precision. With rigorous quality control and a wide range of valve types, Miwival ensures reliable performance tailored to your specific application needs.