Segment Ball Valve Benefits: A Smart Choice Over Common Flow Management Tools

What Sets Segment Ball Valves Apart from Standard Flow Management Tools?

Unlike ordinary valves that face issues with blocking, big pressure loss, or poor flow adjustment abilities, segment ball valves have a special V-notch shape. This allows accurate fluid regulation, strong sealing, and automatic cleaning action—perfect for difficult tasks.

Understanding Segment Ball Valve Build and Operation

Segment ball valves, also called segmented or V-port ball valves, merge the flow adjustment features of globe valves with the high flow capacity of rotary valves. Their key part is a notched or V-shaped ball piece that turns inside the valve body to manage flow. This build creates a cutting motion between the segment and seat, which works especially well with stringy or thick mixtures. The turning movement also allows compact size and efficient power operation.

These valves provide changeable sealing for exact control in on-off and flow management uses. With a cutting action and percentage flow behavior, they are an ideal control ball valve answer.

Comparison with Gate, Globe, and Butterfly Valves

Compared to standard flow management choices like gate, globe, and butterfly valves, segment ball valves offer a better mix of control accuracy and long service life. Gate valves are mainly made for simple on/off tasks with limited flow adjustment abilities. Globe valves give good flow control but have high pressure loss because of their twisted flow path. Butterfly valves are small but find it hard to seal tightly in high-pressure or rough conditions.

Segment ball valves solve these problems by providing both tight closure and excellent adjustment abilities in one design. Their turning movement causes less wear on seals compared to straight-moving gate or globe valves.

Flow Behavior and Control Accuracy

The V-notch shape of segment ball valves creates an equal-percentage flow pattern. This gives finer control at small openings and greater flow at large openings. This makes them highly effective for adjustment tasks where exact flow management is critical. These valves work exceptionally well as capacity control devices, outlet valves, and flow management valves.

Miwival knows customers often find it hard to balance exact flow control against valve service life—segment ball valves fix this by mixing high adaptability with long-lasting build.

Where Do Segment Ball Valves Perform Best?

From pulp and paper making to chemical handling and water cleaning, segment ball valves work better than traditional choices by resisting jamming, rust, and wear—ensuring long-term dependability in severe conditions.

Pulp and Paper Making

In pulp and paper processing, substances like thick mixtures and stringy pulp can block common valve types. The cutting action of segment ball valves stops fiber buildup while ensuring smooth operation even in dense material flows.

Often used in tissue making, these valves are perfect for managing thickness levels in pulp lines or controlling discharge from refiners.

Chemical and Petrochemical Handling

In chemical settings where damaging liquids or changing process states exist, segment ball valves provide reliable results because of their tough build materials and strong closure abilities. They work well with pure liquids and thick mixtures alike, making them useful across different chemical processes.

Water Cleaning and Power Production

For water cleaning plants dealing with dirt-filled flows or power creation places needing exact steam adjustment, segment ball valves give trustworthy service over long periods. Their ability to resist clogging keeps downtime low in important systems.

Miwival tackles field-specific problems by offering segment ball valve answers made to fight clogging, wear, and rust—major troubles faced in these demanding uses.

How Do Segment Ball Valves Boost Working Efficiency?

By lowering pressure drop, increasing flow capacity, and needing less turning force, segment ball valves improve energy use and system results—delivering lasting cost savings.

Lower Pressure Loss and Higher Flow Capacity

Because of their smooth internal shape, segment ball valves minimize pressure loss while increasing flow rate. Unlike globe or angled designs that push fluid through narrow paths, the turning movement enables efficient open-channel flow.

High Adaptability for Exact Adjustment

Segment ball valves usually offer adjustment ratios up to 200:1 or more—much higher than those of traditional globe or butterfly designs. This lets operators fine-tune process amounts without constant valve changes.

Reduced Turning Force Needs and Smaller Power Device Sizing

The decreased friction from turning movement means less turning force demands during operation. As a result, smaller power devices can be used compared to those needed by straight-moving choices—cutting setup costs and energy use.

Miwival helps plant technicians lower energy expenses through smart power device sizing made possible by the low-turning-force features of its segment ball valve products.

Why Are Segment Ball Valves More Economical Long-Term?

Their self-cleaning action, strong build, and extended working life lead to fewer replacements and maintenance stops—providing major long-term savings.

Lower Maintenance Needs Due to Self-Cleaning Action

The cutting motion between the V-notch segment and seat works as a self-cleaning method that stops material buildup—especially helpful in thick or stringy uses where other valve types would need frequent cleaning or replacement.

With this cutting action, these valves keep working correctly longer than most traditional choices.

Long Service Life in Rough and Corrosive Uses

Built from hardened metal mixes or rust-resistant materials like stainless steel or Hastelloy®, segment ball valves withstand harsh process states that would damage standard gate or globe designs quickly.

Longer Service Life Compared to Traditional Valves

Their simple turning system reduces wear points like stem packing damage common in rising-stem designs. This results in fewer stops for repair over the valve’s lifetime.

Miwival’s customers gain from lasting savings due to fewer maintenance periods—a key advantage when looking at total ownership cost over time.

How Do Segment Ball Valves Improve System Dependability?

From tight closure to clog resistance, segment ball valves ensure steady results in frequent-operation tasks—reducing process interruptions.

Strong Closure Abilities with Metal or Soft Seating Choices

Segment ball valves come with either metal-to-metal seats for high-heat/rough jobs or flexible soft seats for complete closure in common service uses—offering choices based on system needs.

Changeable closure choices ensure steady sealing results across different working states.

Resistance to Blocking in Thick or Sticky Media

The self-cleaning V-notch design is especially good at preventing jams—a common failure point for traditional globe or diaphragm controls when handling sticky materials.

Steady Results in Frequent-Use Tasks

Turning movement reduces stem wear during repeated operations, making segmented designs perfect for automated systems needing regular action without losing accuracy over time.

Miwival focuses on system working time by providing reliable segmented answers proven under frequent industrial operations where regular choices fail.

What Should Be Thought About When Picking a Segment Ball Valve?

Choosing the right valve involves checking pressure, heat, material type, and automation fit—ensuring best results and long service.

Use Factors: Pressure, Heat, Material Kind

Knowing process amounts like highest pressure ratings, heat changes, liquid thickness, roughness, or corrosiveness is essential when selecting any control valve—including segmented types—to ensure suitability with working demands.

Material Choice for Body, Internal Parts, and Sealing Pieces

Correct material matching (e.g., stainless steel body with tungsten-carbide coated parts) ensures best resistance against wear/corrosion while keeping seal strength under heat stress cycles common in industrial places.

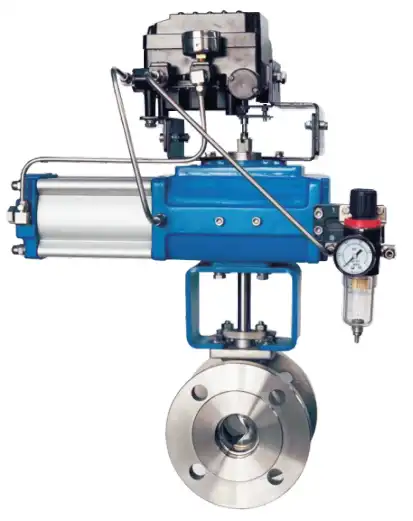

Automation Fit: Air-Powered, Electric, Hydraulic Operation

Fit with existing automation systems should be checked—including feedback tools like positioners—as many segmented designs support connection to modern control systems easily through air-powered/electric/hydraulic operation choices.

Miwival aids customers through expert advice during selection stages—ensuring each part matches process needs while being automation-ready immediately.

Who Is Miwival, and Why Pick Them as Your Segment Ball Valve Provider?

Miwival focuses on high-performance segment ball valves, offering custom answers supported by worldwide service and strict quality rules.

About Miwival’s Product Knowledge

Miwival concentrates only on advanced flow management tools including segmented ball valve systems made for long service under extreme states. Their product range supports both simple on/off tasks and exact adjustment work across fields from pulp & paper to petrochemicals.

Dedication to Quality, New Ideas, and Custom Building

Each Miwival valve goes through strict testing steps matching global rules (API/ANSI/ISO), ensuring steady results backed by creative features like anti-cavitation parts or noise reduction packages made for specific use needs.

Worldwide Supply Ability and Technical Help Services

With a worldwide presence supported by local supply centers and engineering teams familiar with area rules—Miwival gives fast delivery times plus full technical help throughout the product life—from choice through setup & maintenance training plans.

Conclusion

Segment ball valves offer a better choice than traditional flow management answers by mixing exact adjustment, long service life, and efficiency in one design. Their V-notch shape ensures excellent flow control performance, reduced pressure loss, and resistance to blocking—making them perfect for demanding fields like pulp & paper, chemical handling, and water cleaning. With lower maintenance needs, longer service life, and automation fit, segment ball valves provide lasting cost savings and better system dependability. Miwival focuses on high-quality, custom-built segment ball valve answers, supported by worldwide service and technical knowledge, ensuring best results for your specific use needs. Pick segment ball valves for smarter, more efficient flow management.

Common Questions About Segment Ball Valves

What is the main benefit of a segment ball valve compared to a globe valve?

Segment ball valves give higher flow capacity with lower pressure loss because of their smooth turning build while still offering exact adjustment abilities like globe-style controls—but without the related energy waste from twisted flow paths.

Can segment ball valves manage rough or thick mixture media?

Yes. The self-cleaning cutting action between the seat and V-notch makes them particularly suitable for rough mixtures where standard straight-moving designs may jam or wear out fast over time.

Are segment ball valves fit for both on/off and adjustment control?

Completely. Segmented ball valves offer changeable sealing for exact control in on-off and flow management uses. They perform double roles well thanks to flexible seating choices combined with equal-percentage features perfect for adjustment tasks.