Solving Erosion & Coking: Why Eccentric Rotary Valves Outlast Globe Valves in Tough Services

In industrial processes, valves face brutal conditions every day. Slurries packed with abrasive particles grind away at surfaces. Coking fluids build up deposits that jam mechanisms. Traditional globe valves, common in many plants, often buckle under this punishment. They wear out fast, leading to frequent shutdowns, costly repairs, and lost production time.

But there’s a better option. The eccentric rotary plug control valve steps in where others fail. It handles these harsh flows with ease and lasts much longer. Let’s dive into why this design changes the game for tough services.

The Pain Points of Traditional Valves in Abrasive and Coking Applications

Picture a mining operation moving thick slurry through pipelines. Or a refinery dealing with heavy residues that coke up quickly. In these setups, valve failure isn’t just inconvenient—it’s expensive.

Globe valves, for instance, rely on linear motion. The plug slides directly against the seat, creating constant friction. Add abrasive particles or sticky fluids, and erosion accelerates. Seats score and leak. Stems gall. Before long, you’re pulling the valve for maintenance—sometimes every few months.

Ball valves aren’t much better in these spots. Their full-contact rotation traps particles, leading to scoring and seizure. In coking services, deposits build between the ball and seat, making tight shutoff impossible over time.

The result? Higher downtime. Skyrocketing repair bills. And safety risks from leaks. Plants in mining and refining know this cycle all too well. One major refinery reported replacing control valves in delayed coker units multiple times a year due to coking and erosion.

How Eccentric Rotary Plug Control Valves Tackle the Problem Head-On

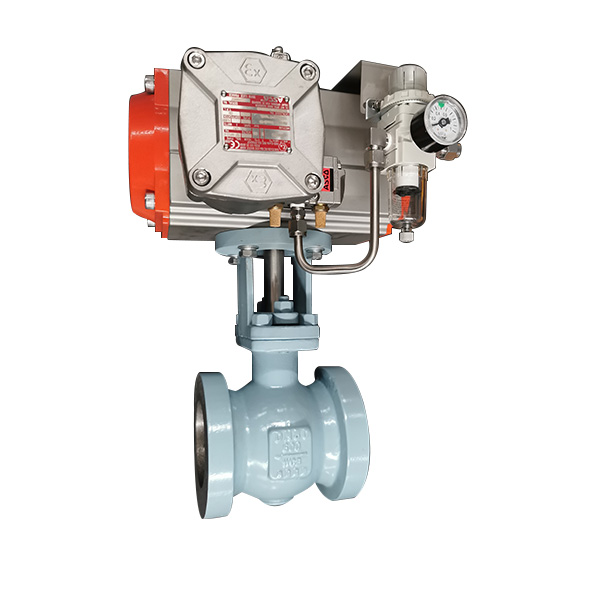

Enter the eccentric rotary plug control valve. This design blends the precise control of a globe valve with the quarter-turn ease of a rotary one. At its core is an offset plug that rotates eccentrically.

Here’s the key: that cam-like action. As the valve opens, the plug cams away from the seat immediately. No rubbing. No friction during most of the stroke. Only at the very end, when closing, does the trailing edge gently contact the seat first. Then, a slight flex in the plug arms presses the face fully against the seat for a tight seal.

This simple motion makes all the difference:

- Zero friction in throttling: Particles don’t get ground between plug and seat, slashing erosion.

- No trapping spots for coking: Fluids flow smoothly without buildup in critical areas.

- Long-term tight shutoff: Meets ANSI Class V (metal seat) or VI (soft seat) standards, even after thousands of cycles.

Compared to globe valves, these offer a higher turndown ratio—often 100:1 versus the typical 50:1 for globes. That means stable control across a wider flow range, without hunting or instability.

Real-World Performance in Mining and Refining

Take a large copper mine in South America. They handled abrasive slurry with high solids content. Globe valves in their flotation circuits lasted barely six months before leaking badly. Switching to eccentric rotary plug control valves changed everything. Erosion dropped dramatically thanks to the no-friction design. Maintenance intervals stretched to years instead of months. Total downtime fell by over 60%.

In petroleum refining, delayed coker units push valves to the limit with hot, viscous fluids prone to coking. One plant in the Middle East battled constant seat damage on their globe-style controls. After installing eccentric rotary versions, they saw virtually no coke adhesion issues. The cam action kept surfaces clean, and shutoff stayed reliable. Operators reported a 40-50% drop in valve-related delays.

These aren’t isolated stories. Across petrochemicals, power plants, and pulp mills, the pattern holds. The valve’s rugged metal trim and streamlined flow passages stand up to slurries, fibers, and sticky residues.

Key Benefits at a Glance

|

Challenge |

Traditional Globe/Ball Valves |

Eccentric Rotary Plug Control Valve |

|

Erosion from abrasives |

High wear on seats/stems |

Minimal – cam action avoids contact |

|

Coking buildup |

Deposits jam mechanisms |

Clean flow, no trapping |

|

Maintenance frequency |

Every few months |

Years between overhauls |

|

Flow rangeability |

Limited (50:1 typical) |

Wide (100:1) for stable control |

|

Shutoff reliability |

Degrades quickly |

Long-term Class V/VI |

Lowering Total Cost of Ownership in Tough Services

It’s not just about lasting longer. Eccentric rotary plug control valves cut the total cost of ownership (TCO) in real ways.

Fewer replacements mean less spending on spares. Reduced downtime boosts production—think thousands of dollars saved per hour in a refinery. Easier actuation (quarter-turn) lowers energy use for operation. And with sizes from 1″ to 16″ and ratings up to ANSI 600, they fit most lines without custom work.

One fertilizer plant calculated their switch yielded a payback in under 18 months, thanks to slashed maintenance and higher uptime.

About Miwival: Your Partner in Valves, Actuators, and Accessories

Miwival stands out as a reliable one-stop supplier for valves, actuators, and accessories. With a focus on flow control expertise, we stock a wide range of products designed for compatibility, quality, and real-world performance. Our team knows the ins and outs of tough applications, from mining slurries to refining processes. We prioritize quick delivery—often in two weeks—and 24/7 support to keep your operations running smoothly. Backed by a commitment to safety and innovation, Miwival delivers solutions that help plants worldwide cut costs and boost reliability.

Conclusion

When erosion and coking shorten valve life, sticking with old designs just doesn’t make sense. The eccentric rotary plug control valve offers a smarter path—proven resistance to wear, better control, and years of trouble-free service. In demanding industries like mining and refining, it’s proving its worth daily by keeping flows steady and costs down.

Ready to extend your valve life and trim maintenance headaches? Reach out today for details on how these valves can fit your process. Let’s talk about lowering your TCO.

FAQs

What makes the eccentric rotary plug control valve better for erosive slurries?

The cam-like motion keeps the plug from rubbing against the seat during opening and closing. In slurries full of grit, this means far less wear compared to valves with constant contact.

How does an eccentric rotary plug control valve handle coking fluids?

Coking happens when residues build up. This design’s smooth rotation and offset plug prevent trapping deposits, keeping the seating surfaces clean and shutoff tight over time.

Can eccentric rotary plug control valves replace globe valves in most applications?

Yes—they handle at least 80% of typical globe valve duties, with advantages like wider flow range and less maintenance in tough services.

What industries benefit most from eccentric rotary plug control valves?

Mining for abrasive slurries, petroleum refining for coking units, petrochemicals, and power plants dealing with hard-to-handle fluids see the biggest gains in longevity and performance.

How much longer do these valves typically last in severe service?

In real installations, they’ve gone from months to years between repairs, cutting replacement needs by half or more depending on the application.