The Smart Choice: How to Extend Relief Valve Service Life with Proper Maintenance

Imagine you’re halfway through a brutal 12-hour shift at a refinery. Steam lines are screaming, pumps are thumping, and out of nowhere an alarm blares—pressure just spiked because a relief valve hung up for half a second too long. Crew scrambles, production stops, and the clock on downtime starts ticking loud. We’ve all been there, or close enough. That little valve sitting quietly on the pipe rack is supposed to be the hero, not the headache. The truth? Most relief valves give up way before their time—not because they’re poorly made, but because nobody gave them the attention they actually need.

Get the care part right and a valve that used to last 18 months can easily run four, five, even seven years without a hiccup. Real shops are doing it right now. One Midwest power station went from swapping valves twice a year to once every three. A paper mill down south cut emergency call-outs by 70% just by sticking to a simple routine. Bottom line: a few hours of smart work beats thousands of dollars in rush replacements every single time.

Why Bother with Relief Valve Maintenance? The Payoff in Black and White

A decent industrial relief valve isn’t pocket change—figure anywhere from five hundred to five grand a pop. Let them sit and rot, and you’re buying new ones constantly. Baby them a little, and the same valve keeps protecting your system for years longer. The math is pretty hard to argue with.

Plants that stay on top of their safety valves see failure rates drop as much as 40%, according to the folks who write the ASME codes we all live by. That’s not marketing fluff; that’s real-world numbers from boilers, refineries, and chemical lines. One wastewater crew we know knocked leak-related losses down 35% in a single year—money that used to vanish into the drain now stays in the budget.

Think of it like tires on your pickup. Run them bald and you’re stranded on the side of the highway. Rotate, balance, keep the pressure right, and they’ll carry you 80,000 miles easy. Same deal with relief valves.

Spotting Trouble Early: Common Signs Your Relief Valve Needs Attention

Catching problems early is half the battle. These valves will usually tip you off long before they quit completely.

-

A slow weep or puff of steam around the seat almost always means trash got trapped on the disc.

-

That annoying machine-gun chatter you hear? The valve’s fluttering instead of snapping shut clean—usually vibration or a tired spring.

-

Gauges creeping 5-10% above or below set point? Drift like that screams worn parts.

-

Rust blooms or tiny pits on the body? Corrosion is eating your margin for error.

| Warning Sign | What You’ll Notice | Usual Culprit | Fast Move |

|---|---|---|---|

| Slow leak | Drips or light steam | Dirt on the seat | Clean and lap the seat |

| Chattering | Rapid pop-pop-pop sound | Vibration or wrong spring | Check mounting, add damping |

| Pressure creep | Gauges off normal range | Spring fatigue | Bench test and adjust |

| Corrosion damage | Pitting, flaking, or red rust | Aggressive process fluid | Inspect internals, protect |

Walk the lines once a week with this short list in your head and you’ll head off most grief before it turns into a full-blown mess.

Hands-On Maintenance: Step-by-Step Guide to Longer Valve Life

Here’s the playbook plenty of sharp crews already run. Nothing exotic—just stuff that flat-out works.

Cleaning: Get the Gunk Out

Crud kills valves faster than anything else. Every three months (or monthly if you’re in a dusty or sticky service), isolate the valve, blow it down, and flush with something that won’t hurt the trim. Steam valves? Drain the condensate first so you’re not blasting scale deeper. Pull the bonnet if you have to, but mind that spring—it’s loaded. Soft rag on the seat, no scotchbrite. One sugar plant started running filtered water through the lines and instantly doubled the time between cleanings.

Inspection: Look Close, Look Often

Every quarter, crack it open and really look. Disc pitted or wire-edged? Spring crooked or binding? Measure the set pressure cold—it better be within a couple percent. Torque every bolt to spec; loose flanges leak every time. A good flashlight and a cheap bore scope pay for themselves the first time you spot a cracked disc nobody else saw.

Testing: Make It Pop Right

Once a year, prove it still works. Bench test is king, but in-line lift devices get the job done when pulling the valve isn’t practical. It needs to crack at set pressure, lift full, and reseat tight—no simmer, no hang-up. Anything more than a pound off and you’re adjusting or rebuilding. Plenty of power plants stretch the interval to 18 months once they prove the valves stay steady.

Quick kit every tech should have in the truck:

-

Torque wrench

-

Good 0-600 psi test gauge

-

Clean rags and solvent

-

Calipers and a small mirror on a stick

Log every test. Patterns jump out fast—seasonal corrosion, vibration wear, whatever. Fix the pattern, not just the symptom.

Real-World Wins: Stories from the Field

A palm oil plant in Malaysia used to eat relief valves for lunch—heat, humidity, and sticky residue finished them off in about 15 months. They started blowing the lines clean every two months, added a cheap inhibitor to the boiler feed, and put vibration pads under the compressors. Average life shot past four years. Harvest season went from panic mode to business as usual.

Up in a cement kiln outside Denver, fine dust was the killer. They added automatic air purges after every shift and started a 30-minute monthly blow-down. Chatter disappeared overnight. Valves that used to last 20 months started hitting five years easy, and the kiln’s fuel burn dropped 8% because pressure stayed rock steady.

That’s not luck—that’s just doing the basics really well.

Discovering Miwival: Your Partner in Flow Control

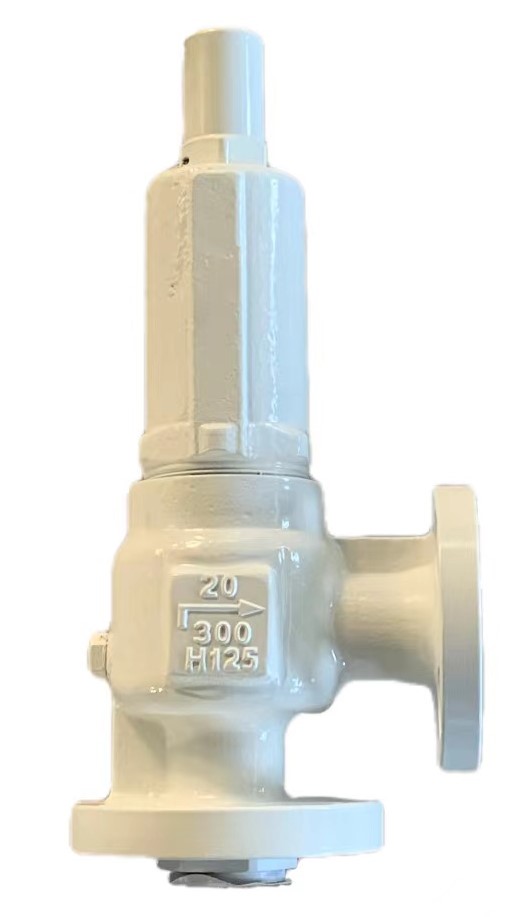

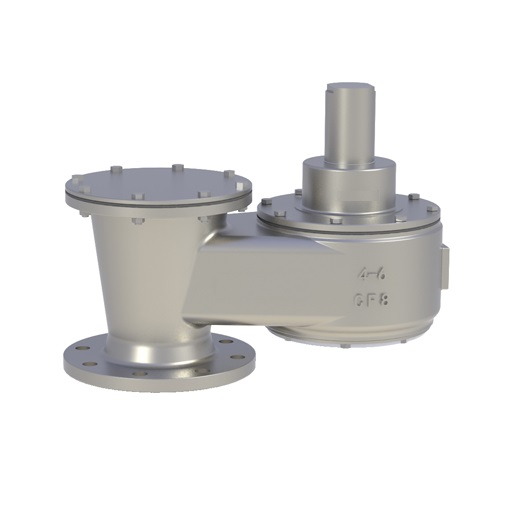

If you’re hunting solid gear that’s built to last and backed by people who actually pick up the phone, take a hard look at Miwival. They supply valves, actuators, and all the accessories plants actually need—everything from spring-loaded relief valves tough enough for nasty chemicals to pilot-operated safety valves that laugh at high-pressure steam. Stock ships fast, usually inside two weeks, and their tech crew is on call around the clock. Over 40 countries run their stuff in mines, power stations, refineries—you name it. When you pair their gear with the kind of maintenance we just covered, downtime becomes a rare visitor.

Wrapping It Up: Make the Smart Choice Today

It all comes down to staying one step ahead. Spot the little stuff early, clean like you mean it, test like the code guys are watching (because they are), and tweak the plan when your plant throws you curveballs. Do that and your relief valves stop being expenses and start being the reliable teammates they were designed to be. Less money flying out the door, fewer gray hairs, and a whole lot more sleep at night. Start tomorrow morning—your next shutdown avoided is waiting.

FAQs

How often should I check a relief valve to keep it running for years? Quarterly eyeball checks and yearly pop tests cover most services. If you’re in dusty or corrosive hell, go monthly on the visuals. Catching things early is the single cheapest insurance you’ll ever buy.

What kills most relief valves out in the field? Plain old dirt on the seat—hands down. A regular flush and a clean inlet screen fix 80% of the headaches we see on service calls.

Can good maintenance really let a safety valve live twice as long in steam service? Easy. We’ve watched plants take valves from two-year wonders to six-year champs just by staying religious about scale control and spring checks.

What basic tools do I need to take care of relief valves myself? Grab a torque wrench, a decent test gauge, some solvent, and clean rags. That’s honestly it for 90% of the work. The rest is just showing up on schedule.