Understanding the Function of a KGV Knife Gate Valve: A Comprehensive Guide

In the world of industrial flow control, getting the right valve can make or break your operations. Picture this: a bustling mining site where thick slurry pumps through pipelines, and one faulty shutoff could mean hours of cleanup and lost production. That’s where a solid knife gate valve steps in. Specifically, the KGV knife gate valve stands out for its straightforward design and tough-as-nails performance. If you’re dealing with abrasive slurries, viscous fluids, or just need reliable isolation in tough spots, this guide breaks it down. We’ll walk through how it works, why it matters, and tips to keep it running smooth. Whether you’re an engineer tweaking a wastewater setup or a plant manager eyeing uptime, stick around—you’ll walk away knowing exactly what makes the KGV tick.

What Is a Knife Gate Valve?

At its core, a knife gate valve is a simple beast built for on-off control in pipelines carrying messy, heavy-duty stuff. Think of it as the no-frills workhorse of the valve family. Unlike fancy ball valves that spin or globe valves that throttle with precision, knife gate valves are all about slicing through flow and sealing it tight when you need to.

The design boils down to a flat blade—shaped like a knife edge—that slides up and down inside the valve body. When open, the blade lifts clear, letting media rush through with minimal resistance. Close it, and that sharp edge cuts right into the flow, wiping away buildup as it seats against the body. It’s compact, lightweight, and doesn’t take up much space in your piping run. Sizes typically run from a couple inches to over 24 inches in diameter, handling pressures up to 150 PSI or more, depending on the build.

But why “knife”? That edge isn’t just for show. It shears through solids like fibers or chunks in pulp, making it a go-to for industries where clean media is a pipe dream. In real terms, imagine a paper mill churning out slurry loaded with wood pulp. A knife gate valve here prevents clogs that could halt the whole line, saving you from that dreaded downtime call at 2 a.m.

Diving Deeper: The Function of a KGV Knife Gate Valve

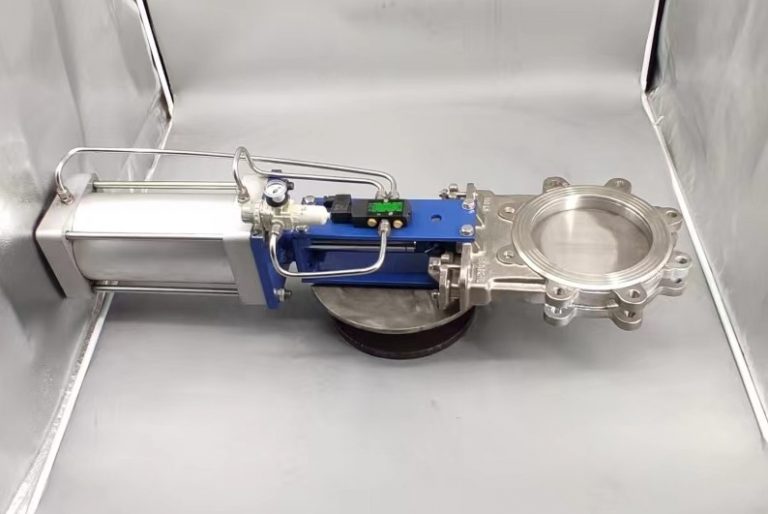

Now, let’s zero in on the KGV knife gate valve. What sets it apart? It’s engineered for those brutal conditions where standard valves would choke and fail. The “KGV” tag points to a robust model optimized for heavy slurries and isolation duties, with a gate that’s reinforced for extra bite.

How It Works: Step by Step

Open the bonnet, and you’ll see the gate poised like a guillotine. Here’s the play-by-play:

-

Open Position: An actuator—manual handwheel, pneumatic cylinder, or electric motor—lifts the stainless steel gate fully. Flow path opens wide; low pressure drop means your pump doesn’t strain.

-

Closing Action: As the gate drops, its beveled edge meets the seat. It doesn’t just stop flow—it “knifes” through any solids, breaking them up or pushing them aside. Full closure happens in seconds, often under 5 for automated setups.

-

Sealing Mechanism: The gate presses against a resilient seat, usually EPDM or PTFE, creating a bubble-tight seal. In KGV models, this seat is often replaceable from the top, no pipeline disassembly needed.

-

Throttling Option: While primarily for isolation, some KGVs allow partial opening for basic flow control. But heads up—it’s not for fine-tuning like a control valve; push it too hard, and you’ll wear the gate unevenly.

In action, consider a cement plant’s slurry line. That KGV drops in, handles 70% solids by weight, and shrugs off abrasive silica like it’s nothing. Data from field runs shows these valves lasting 5-10 years in such spots, versus 2-3 for weaker designs. It’s physics at work: the knife edge distributes pressure evenly, cutting erosion by up to 40% compared to flat gates.

Key Components and Their Roles

Breaking it down further helps see why the KGV shines. Here’s a quick rundown:

| Component | Material Options | Primary Function | Pro Tip for Longevity |

|---|---|---|---|

| Gate | Stainless Steel (316/304) | Slices through media for clean shutoff | Regular inspection for nicks—catches issues early. |

| Body | Ductile Iron or Carbon Steel | Houses the gate; withstands line pressure | Coat with epoxy for corrosive environments. |

| Seat | EPDM, Viton, or Metal | Seals against leakage; resists wear | Swap out every 18 months in high-abrasion use. |

| Stem | Stainless Steel | Connects actuator to gate; rising/non-rising types | Lubricate quarterly to avoid binding. |

| Actuator | Pneumatic/Electric | Powers open/close; failsafe on loss of air/power | Pair with positioners for remote monitoring. |

These parts team up for reliability. In one wastewater treatment plant we heard about, swapping to a KGV cut leak rates from 15% to under 2%, based on monthly audits. That’s not fluff—it’s the gate’s shear action keeping things leak-free.

Where Knife Gate Valves Shine: Real-World Applications

Knife gate valves aren’t one-size-fits-all, but the KGV model? It’s tailor-made for the gritty end of industrial life. From mining ops hauling tailings to power plants managing fly ash, here’s where it fits like a glove.

Mining and Slurry Handling

Mining’s a rough gig—think corrosive brews at 200°F, loaded with rocks. The KGV knife gate valve thrives here, installed at pump discharges or hydrocyclone feeds. It isolates sections fast, preventing spills that could idle a whole shift. Take a copper mine in Arizona: operators reported 25% less maintenance after installing KGVs, thanks to the valve’s ability to handle 1,500 GPM of 40% solids slurry without galling.

-

Pumping Stations: Quick shutoff during repairs.

-

Tailings Lines: Seals against backflow in long runs.

-

Dewatering: Clears sumps without clogging.

Wastewater and Pulp & Paper

In wastewater, KGVs tackle everything from raw sewage to digested sludge. The knife action breaks up rags and debris, keeping flows steady. A Midwest treatment facility saw pump life extend by 18 months after ditching plug valves for KGVs—fewer blockages meant fewer restarts.

Pulp and paper mills love them for stock lines. That fibrous slurry? The gate shears it clean, avoiding the buildup that plagues butterfly valves. One mill cut fiber loss by 10% during shutdowns, per their logs.

Other Heavy Hitters

-

Cement and Power: Fly ash silos or kiln feeds—KGVs lock in dust-tight.

-

Chemicals: Viscous batches where full bore flow matters.

Across these, the KGV’s function boils down to one thing: uptime. Industry stats peg average downtime costs at $50,000 per hour in mining; a reliable valve like this keeps the meter from running.

Advantages That Pack a Punch

Why pick a KGV knife gate valve over the competition? It’s the combo of smarts and strength.

First, cost hits different. These valves run 20-30% cheaper upfront than trunnion ball valves for big bores, with install that’s a breeze—no flanges to fuss over. Operationally, low torque means smaller actuators, trimming energy use by 15% in pneumatic setups.

Durability’s the real winner. The through-going design lets media flush the body, cutting corrosion. In erosion-prone spots, hard-faced gates (like with tungsten carbide) boost life cycles to 50,000 opens/closes. And maintenance? Top-entry access means fixes in under an hour, not a day.

Safety-wise, it’s a quiet hero. Fail-closed actuators prevent runaway flows, and the stem seal keeps hazards contained. One chemical plant avoided a $100K spill fine after their KGV held during a pressure surge—real stakes, real savings.

Downsides? It’s not for high-pressure steam or precise throttling. But in its wheelhouse, nothing touches it.

Troubleshooting Common Hiccups

Even the best setups glitch. Drawing from shop floor stories, here are pitfalls and fixes for your KGV.

-

Leakage at Seat: Often from debris. Flush lines pre-close; inspect seats yearly.

-

Gate Sticking: Buildup city. Use purge ports to blast it clean—cuts failures by 60%.

-

Actuator Lag: Air supply woes. Check filters monthly; add regulators for steady performance.

A quick bullet list of prevention plays:

-

Train ops on full-stroke cycles to even wear.

-

Log cycles—replace at 80% of rated life.

-

Pair with flow meters to spot early drags.

In a recent cement op, routine stem lubes dropped binding incidents from 12 to 2 annually. Small habits, big wins.

Discover Miwival: Your Go-To for Valves and Automation

Before we wrap up, a quick nod to the folks making these KGVs hum: Miwival. As a dedicated supplier of valves, actuators, and accessories, Miwival brings a fresh take to flow control. Their lineup, including top-notch knife gate valves like the KGV, is built for the long haul in spots like mining and wastewater. What sets them apart? It’s that one-stop vibe—everything from stock bodies to custom actuators, all under one roof. With a crew that’s hands-on and tuned into real-world headaches, they deliver setups that just work. Mission’s clear: safer ops through smart automation. If you’re scouting reliable gear that doesn’t break the bank, Miwival’s got your back.

Conclusion

Wrapping it up, the function of a KGV knife gate valve isn’t flashy—it’s foundational. From shearing slurries in a mine to sealing sludge in treatment plants, it delivers isolation you can count on, backed by a design that’s equal parts simple and sturdy. We’ve covered the nuts and bolts, real-spot wins, and even those gotcha moments to dodge. Bottom line: in an industry where every minute counts, a solid KGV keeps things moving without the drama. If your setup’s pushing limits, it’s worth a closer look. Ready to upgrade? Dive into options that fit your flow.

FAQs:

What exactly does the function of a KGV knife gate valve involve in daily operations?

The main gig for a KGV knife gate valve is straightforward isolation—dropping that blade to cut off flow in pipelines hauling tough stuff like slurries. It shines in on-off duties, with the knife edge clearing solids for a tight seal, all while keeping pressure drops low to ease up on your pumps.

How does a knife gate valve like the KGV handle abrasive materials without failing quick?

It tackles abrasives head-on with a beveled gate that shears through them, plus seats made from wear-resistant stuff like EPDM. In mining runs, for instance, this setup often doubles the service life compared to basic gates, based on field wear data.

Can I use a KGV knife gate valve for throttling flow, or is it strictly shutoff?

Mostly shutoff, but it can handle light throttling in a pinch. Just don’t push it for fine control— that invites uneven wear. For slurry lines, partial opens work okay for rough adjustments, but pair it with dedicated controls for anything precise.

What’s the typical lifespan of a KGV knife gate valve in heavy industry?

In spots like cement or wastewater, expect 5-10 years with regular checks. Factors like media abrasiveness play in—one pulp mill hit 8 years on theirs by flushing lines weekly, cutting erosion way down.

How do I pick the right size and material for my knife gate valve setup?

Start with flow rate and pipe diameter—aim for full bore to minimize drops. For corrosives, go stainless or coated bodies; slurries call for carbide-tipped gates. Chat specs with a supplier to match your pressures, usually up to 150 PSI for most KGVs.