Unlocking the Potential of Gate Valve in Diverse Applications

Gate valves are important parts in fluid control setups. They give dependable shut-off abilities across many fields. Their strong build, low pressure drop, and two-way sealing make them perfect for uses from oil and gas pipelines to city water systems. This article looks at their operation, industrial benefits, and choices for customization. It shows how Miwival gives made-to-order answers to meet worldwide needs with quality-checked items.

What Are Gate Valves and How Do They Function?

Gate valves are a basic part in fluid control setups. They are known for giving tight shut-off in both ways. Their plan lets them be used in many situations. This is especially true where full flow or no flow states are needed.

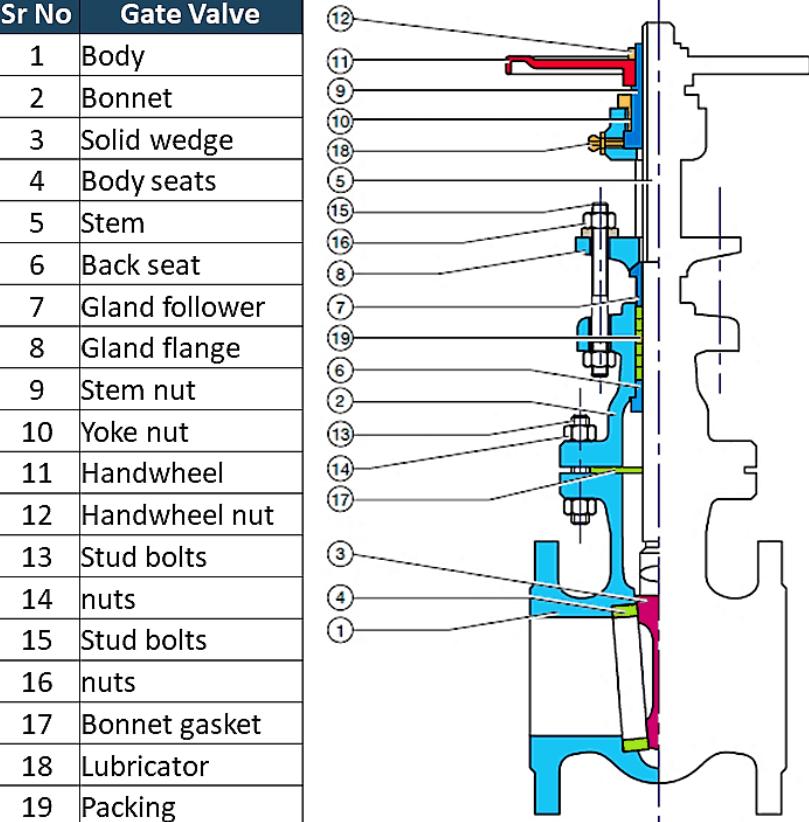

Basic Structure and Parts of a Gate Valve

A gate valve has several key pieces: the main body, top cover, moving rod, closure part (or wedge), and seal rings. The closure part is the main piece that moves up and down to open or shut the valve. The moving rod links the driver or handwheel to the closure part. It passes on the motion. The main body holds all inside pieces and keeps pressure in.

How They Work: Rising Moving Rod vs. Non-Rising Moving Rod

Gate valves can be grouped by moving rod action into rising moving rod and non-rising moving rod kinds. In rising moving rod gate valves, the moving rod clearly moves up when the valve opens. This gives a clear sign of the valve’s place. Non-rising moving rod valves have a fixed rod that turns inside the valve body. This is good for setups with little space.

Usual Stuff Used in Making Gate Valves

Gate valves are made from different stuff based on what the job needs. Common stuff includes cast iron, bendable iron, carbon steel, rustless steel, copper mix, and special metals like Monel or Hastelloy for harsh places. Stuff choice makes sure it works with the fluid kind and working states.

Miwival offers both rising and non-rising moving rod plans made from lasting stuff like rustless steel and cast steel. They meet different working needs while making sure of long life in tough places.

Why Are Gate Valves Chosen in Industrial Uses?

Gate valves are widely picked across fields because of their strong make and great sealing power under high-pressure states.

Benefits of Gate Valves Over Other Valve Kinds

One main plus is their low pressure drop when wide open. This comes from straight flow paths. They also give two-way sealing and are good for stopping flow, not controlling it. Compared to globe or ball valves, gate valves offer cheap answers for big-pipe lines.

Problems and Things to Think About in Industrial Use

Even with their gains, gate valves are not great for flow control. Partly opening them may cause shaking or wearing of the seal faces. They also need more turns to work than quarter-turn valves. They might not be right for fast shut-off jobs.

Miwival deals with these problems by giving planned answers made for exact industrial cases. They make sure of the best sealing while cutting down upkeep needs, even under high-use work.

In Which Fields Are Gate Valves Often Used?

Gate valves act as key framework in many fields. This is because they can work across different pressure levels, heat ranges, and fluid kinds.

Oil and Gas Field

In drilling and refining steps, gate valves handle crude oil, natural gas, steam, and oil products under very high pressures. Their ability to give full-pipe flow makes them perfect for cleaning jobs in pipelines.

Water Cleaning and Supply Setups

City water services lean heavily on gate valves for cutting off parts during fixes or sudden problems. Their rust-stopping covers make sure they last long, even when around cleaned or dirty water for a long time.

Chemical Making Factories

Chemical plants need exact stuff matching because of strong fluids like acids or cleaners. Rustless steel or special metal gate valves with plastic linings are often used here for safe holding.

Miwival gives field-specific answers by offering rust-stopping types with special seals. These make sure of long life even in very reactive chemical places. They help different jobs across areas like oil & gas, water systems, and petrochemicals.

How Do Gate Valves Help Framework and Service Plans?

Gate valves form the base of many service setups. They let safe fluid control across big framework webs.

Part in Power Making Places

Heat power plants use gate valves a lot in boiler water lines. High-heat steam must be cut off safely there. Nuclear places also use them because they work well under radiation when made from right stuff.

Use in City Water Supply Webs

In city-wide supply webs, big flanged gate valves are put at joins or branch lines for part cutting during fixes. This makes sure little service break while keeping safety rules.

Use in Dirty Water Handling Setups

Dirty water setups often have rough mixes. So bendable iron or rubber-lined gate valves are chosen. These setups need tight shut-off power without leaking under changing flow states.

Miwival helps framework builders by giving heavy flanged-end gate valves made just for big-flow city plans. They make sure steady work even during pressure spikes or sudden shutdowns.

What Custom Choices Exist for Special Needs?

To meet changing working needs across fields, gate valves come with many custom features. These boost how they work under special states.

Types Based on End Links (Flanged, Threaded, Welded)

End links decide how a valve fits into a pipe setup. Flanged ends let easy putting in or taking out. Threaded ends fit smaller pipes. Welded ends give leak-free joins perfect for high-pressure/high-heat service lines.

Picking Based on Drive Kind (Hand-Operated, Electric, Air-Driven)

While handwheel work is usual in smaller setups, electric drivers let remote control needed for automatic setups like SCADA webs. Air-driven drivers give fast action where pressed air is on site.

Special Covers and Linings for Harsh Places

Protective linings like epoxy or bonded covers stop rust. Plastic linings fight chemical harm. This greatly makes service life longer even under strong fluid contact.

Miwival gives flexible setups. These include electric-drive rustless-steel gate valves with FBE covers. They fit just what buyers need for strength against eating stuff without losing control exactness across many jobs.

How Does Miwival Act as a Dependable Source for Gate Valves?

Miwival has made itself a trusted helper through its promise to building greatness and buyer-focused services made for worldwide industrial needs.

Look at Miwival’s Item Set and Building Know-How

Miwival offers a wide set that includes wedge-type gate valves. These come in sizes from DN50–DN1200 with pressure grades up to PN40/ANSI 600#. Their building group helps buyers choose valves based on fluid traits, pressure levels, heat limits, drive likes—and more.

Quality Check Rules and Papers Held by Miwival

All Miwival items go through strict checks by world rules like API 600/ISO 9001/EN 1074. This makes sure fault-free sending backed by traceable papers, including MTCs (Material Test Certificates).

World Supply Power and Buyer Help Services

With smartly placed storehouses across lands and many-language help teams, Miwival makes sure on-time sending plus after-sale help. This includes putting-in help and problem-solving by far checks or site trips if needed.

By matching item building with real-world job needs—from sea rigs to city pipelines—Miwival gives builders worldwide power through steady supply lines. These are backed by building depth rooted in years of site use, helping many jobs across the globe.

Conclusion

Gate valves play a key part across fields because of their strong plan fit for full shut-off jobs under changing pressures and heats. Whether controlling crude oil flows at sea or handling drinking water supplies on land, they give steady work when made right through stuff choice, drive kind, and cover picks. Groups like Miwival make this step smooth by giving building-advanced answers checked by world rules. This makes them a perfect helper for those wanting good work across many jobs.

FAQs About Gate Valves

What is the difference between a gate valve and a globe valve?

A gate valve is mainly used for cutting off flow (wide open/shut), while a globe valve controls flow speed. This is due to its straight-motion disk plan. This offers better flow control traits but higher pressure drop versus gate valves.

Can gate valves be used for flow control jobs?

No; using a gate valve partly open may harm the seal face due to rough flow or shaking. It is not advised for flow control jobs unlike globe or needle valves made just for changing flow.

How do I pick the right gate valve stuff for strong fluids?

Stuff choice depends on fluid traits. Rustless steel fits weak acids/bases. Plastic-lined bodies manage strong chemicals. Double metals like Hastelloy give top fight against chlorides/sulfides often found in chemical plants.