What is an Eccentric Rotary Plug Valve? How It Solves Severe Service Challenges

Ever wondered why some valves just can’t hack it in tough industrial setups? Picture this: a refinery dealing with gritty slurries or a chemical plant battling corrosive fluids. Stuff breaks down fast if the gear isn’t up to snuff. That’s where the eccentric rotary plug valve steps in—like that reliable tool in your garage that never lets you down. In this post, we’ll break down what an eccentric rotary plug valve really is, how it works its magic in harsh conditions, and why it’s a game-changer for folks in heavy industries. Stick around; you might pick up a tip or two that saves your operation a headache.

Understanding the Basics of Eccentric Rotary Plug Valves

Let’s start simple. An eccentric rotary plug valve is basically a control valve with a plug-shaped element that’s mounted off-center from the valve’s main axis. When you turn it, the plug swings along an eccentric path—think of it like a door on a wonky hinge that seals tight without grinding away at itself.

The core idea? That offset design. The plug rotates into and out of the seat without constant rubbing, which cuts down on wear big time. In real terms, this means lower torque to operate—sometimes as much as 50% less than your standard ball valve. And sealing? Spot on, even under high pressure or with sticky fluids.

I remember chatting with a plant manager in a petrochemical facility last year. He was fed up with valves seizing up every few months from abrasive particles. Switched to these eccentrics, and boom—downtime dropped. It’s not magic; it’s smart engineering.

Key Components and How They Work Together

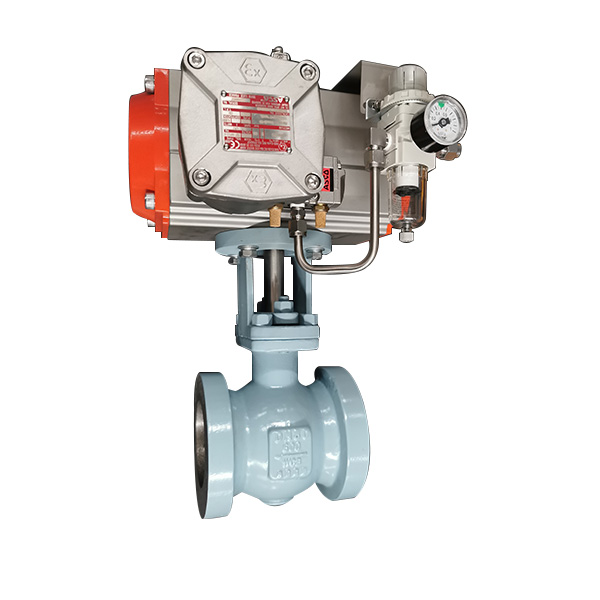

Break it down further: the heart is that eccentric plug, often double-offset for extra bite in severe spots. The body holds everything, usually flanged or wafer-style for easy install. Then there’s the actuator—pneumatic or electric—that does the heavy lifting.

Flow-wise, it’s linear with a high turndown ratio, up to 100:1. That means precise control from a trickle to full blast. Compare that to a typical globe valve’s 50:1, and you see the edge. No more overkill on energy or sloppy regulation.

In action: fluid hits the plug, which cams away from the seat on opening. No friction mid-stroke. Closing? The trailing edge touches first, flexing just enough for a solid seal. Simple, but it handles erosive stuff like coking fluids without batting an eye.

Tackling Severe Service Challenges Head-On

Severe service—high temps, corrosives, abrasives—it’s the stuff that eats valves for breakfast. Traditional options like ball or globe valves? They work okay in mild spots, but push ’em hard, and they falter. Ball valves drop pressure minimally but suck at throttling accuracy. Globes are precise but drag on flow efficiency and rack up maintenance.

Enter the eccentric rotary plug valve. It blends globe-like control with rotary ease. For starters, in slurry handling—say, wastewater with heavy particles—it shines. The minimal contact during operation means less wear, extending life by years in some cases.

Take mining ops. Slurries there are brutal, loaded with grit. These valves manage without clogging or eroding fast, thanks to streamlined passages and rugged metal trims. In one setup I heard about, a power plant swapped in eccentrics for high-pressure steam lines. Result? Better modulation, fewer leaks, and energy savings that paid off the switch in under a year.

Advantages in High-Pressure and Corrosive Environments

Pressure spikes? No sweat. These valves thrive in up to 300 psi classes, with variants like double eccentrics handling even hotter, more corrosive gigs—think 2205 duplex stainless bodies for chemical resistance.

Noise and cavitation? Big issues in fast flows. The eccentric design attenuates that, reducing vibration that could shake pipes loose. And for viscous chemicals or high-temp apps in pulp and paper mills? Enhanced sealing keeps things tight, cutting fugitive emissions.

Here’s a quick comparison to drive it home:

|

Valve Type |

Throttling Accuracy |

Wear Resistance |

Flow Efficiency |

Best For |

|

Eccentric Rotary Plug Valve |

High (100:1 turndown) |

Excellent (minimal friction) |

Balanced |

Severe service, slurries, corrosives |

|

Ball Valve |

Low |

Good |

High (low drop) |

Quick shutoff, clean fluids |

|

Globe Valve |

High |

Moderate |

Low (high drop) |

Precise control, but high maintenance |

|

Butterfly Valve |

Moderate |

Fair |

High |

Large diameters, but poor in abrasives |

See? It’s not about being the cheapest—it’s about lasting longer and working smarter.

Real-World Applications and Performance Data

Let’s get specific. In refining, these valves tackle erosive fluids in coking units. One study from a major operation showed a 30% drop in maintenance calls after adopting them. Petrochemicals? Natural gas lines use ’em for throttling without the usual pressure headaches.

Power plants love ’em for steam control—precise modulation keeps boilers humming efficiently. Even in fertilizers, where corrosives rule, the durability pays off. Data-wise, flow coefficients (Cv) can hit wide ranges, ensuring versatility across rates.

But hey, not everything’s perfect. If your setup’s super low-flow, might need tweaks. Or in ultra-clean pharma? Other valves might edge it out. Still, for severe challenges, it’s tough to beat.

Why Choose Eccentric Rotary Plug Valves for Your Operation?

Versatility’s key. They handle slurries, viscous chems, high-pressure steam—industries like energy, mining, and chemicals swear by ’em. Extended life means less downtime; who doesn’t want that?

Factor in low torque—easier on actuators, cheaper to run. And maintenance? Modular designs let you swap trims without special tools. Your crew can handle it onsite, no shipping off for weeks.

Thinking long-term? With IoT creeping in, these valves integrate digital smarts for predictive fixes. Imagine catching a seal wear before it blows—saves a bundle.

Miwival: Your Go-To Supplier for Eccentric Rotary Plug Valves

Speaking of reliable sources, Miwival stands out as a solid player in the valve game. Founded by valve pros with decades under their belts, we’ve built a rep for quality control valves tailored to tough industries like mining, chemicals, and power. Our eccentric rotary plug valves? Crafted in-house at our Zhejiang and Anhui plant, focusing on precision and durability. From globe styles to these eccentrics, we stock ’em ready for quick delivery. Plus we’re geared for global reach. Check our solutions page for case studies—real wins in severe setups.

Conclusion

Wrapping up, eccentric rotary plug valves aren’t just another piece of kit—they’re problem-solvers for the roughest jobs out there. By cutting wear, boosting control, and handling the nastiest fluids, they keep operations smooth and costs down. If you’re in engineering or plant management, give ’em a look; they might just fix that nagging issue you’ve been wrestling with.

FAQs

What is an Eccentric Rotary Plug Valve, and How Does It Differ from a Standard Plug Valve?

An eccentric rotary plug valve features an offset plug that rotates without constant seat contact, unlike standard plugs that grind more. This setup slashes torque and wear, making it ideal for severe service where regulars fail fast.

How Does an Eccentric Rotary Plug Valve Solve Challenges in Abrasive Fluid Handling?

In abrasive spots like slurries, the eccentric design minimizes friction during strokes, extending life. Real data shows up to 30% less maintenance in mining apps—keeps particles from chewing through trims.

Are Eccentric Rotary Plug Valves Suitable for High-Temperature Applications?

Absolutely. Variants like double eccentrics handle high temps and corrosives in power or refining. Their sealing holds tight, preventing leaks that could spike downtime.

What Maintenance Tips Should I Know for Eccentric Rotary Plug Valves?

Keep it simple: regular checks on actuators and seals. The modular trim swaps easy—no fancy tools. In my experience, catching flex issues early avoids big repairs.

How Can I Select the Right Eccentric Rotary Plug Valve for My Process?

Look at pressure, temp, and media type. For corrosives, go duplex materials; for flow control, aim for that 100:1 turndown. Chat with suppliers like us for tailored fits—beats guessing.