What’s Next for Valve Manufacturing in the Energy World by 2025

Cool Trends in Valve Making

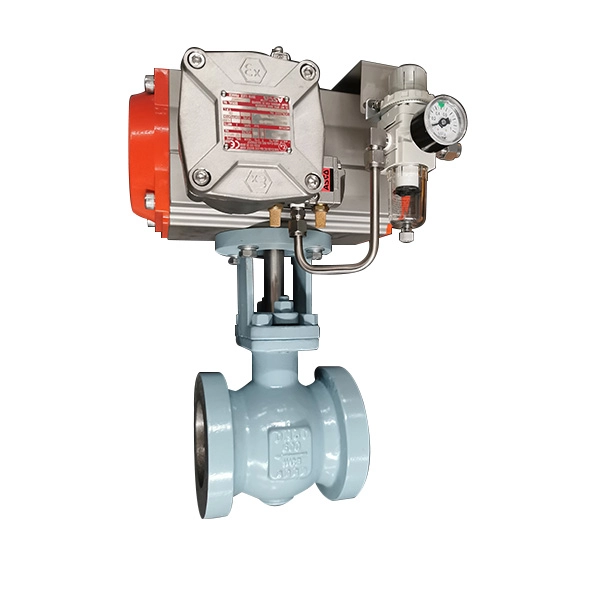

Valves Get Smarter

Valves are getting a high-tech makeover. Imagine them with tiny sensors and internet-connected gadgets. They keep an eye on fluid systems in real time, sending updates on pressure, temperature, and flow to a main system. This helps catch problems early and keeps things running without a hitch. It’s perfect for the energy sector’s push toward automation.

This tech means you can check on systems from miles away. It’s a huge help for places like oil and gas fields, where gear is often in rough or far-off spots. Smart valves make work smoother and save resources.

Going Green with Materials

Everyone’s talking about the environment these days. Valve makers are jumping on board by using stuff like recyclable metals and eco-friendly plastics. It’s all about doing less harm to the planet. Plus, it helps meet strict global rules on pollution.

Even the way valves are made is getting greener. New tricks cut down on waste and use less energy. These steps show companies care about the earth. They also win over customers who want sustainable products.

Custom Valves for Special Jobs

Industries are getting pickier. They want valves built just for them, whether it’s for handling nasty chemicals or working in crazy heat. Valve makers team up with clients to nail down exactly what’s needed.

Designers use fancy tools to test how valves will hold up. This made-to-order approach helps companies shine in unique markets. It also keeps their customers smiling.

Tech That’s Changing How Valves Are Made

Robots and Automation in the Mix

Robots are taking over valve factories. Picture robotic arms assembling and welding with laser-like precision. Automated setups make everything faster and cut down on mistakes.

This tech lets companies ramp up production without losing quality. In the energy world, where reliability is king, automation makes sure valves pass tough tests.

3D Printing Shakes Things Up

3D printing is a total game-changer for valves. It lets makers create wild shapes that used to be too pricey or tough to pull off. It’s awesome for whipping up prototypes fast, so new valves hit the market sooner.

It also means spare parts can be printed when needed. That saves money and time. Plus, 3D printing cuts waste and opens the door to creative designs that work better.

Tougher Materials for Stronger Valves

New materials like super-strong alloys and ceramics make valves last longer. They handle wear, rust, and blazing heat like champs. These are great for heavy-duty jobs in oil, gas, and power plants.

Special coatings add extra protection against rough conditions. These upgrades mean valves stay reliable and need fewer fixes, saving cash in the long run.

How the Energy Shift Impacts Valves

Keeping Up with Clean Energy

The world’s going big on renewable energy. Solar farms need valves that can handle super-hot steam. Wind turbines need precise valves for their hydraulic systems.

As clean energy projects pop up everywhere, valve makers have to step up. They’re building products that fit these new needs while keeping things green.

Valves for Hydrogen and Carbon Capture

Hydrogen and carbon capture are huge for reaching zero-emission goals. Valves for hydrogen need to handle high pressure without letting tiny molecules slip through.

Carbon capture systems need valves with super-tight seals for shifting pressures. Companies are investing big in research to create valves for these key energy systems.

Backing Offshore Wind and Solar

Offshore wind farms deal with salty, corrosive air. They need valves that stay tough for years. Solar thermal plants rely on special fluids controlled by top-notch valves.

With renewable projects spreading across the globe, makers need to adapt. They’re designing solutions for different climates and local rules while keeping performance rock-solid.

Challenges for Valves in 2025

Sorting Out Supply Chain Messes

Supply chains are still a pain for valve makers. Things like global tensions and material shortages cause holdups. In 2025, companies will feel pressure to get parts out on time. One delay in a global chain can throw everything off.

To tackle this, companies are working with more suppliers and buying local when they can. Digital tools track stock and shipping live, catching issues early to keep things moving.

Sticking to Tough Rules and Green Goals

Governments are getting stricter about pollution and sustainability. Valves in oil and gas need to stop leaks and save energy.

Meeting these rules means spending big on research for new materials and designs. Certifications are a must to sell products, but they’re tricky to get. Companies that don’t keep up could lose out to rivals.

Keeping Costs Down While Innovating

High-tech valves like smart ones are cool but pricey. Companies need to offer cutting-edge stuff without jacking up prices.

Mass production helps keep costs low. Modular designs make upgrades cheaper. Teaming up with tech firms also leads to affordable, custom solutions.

Opportunities to Grow in Energy

Breaking into New Markets

Places like Southeast Asia, Africa, and South America are booming. They need energy setups, which means more call for valves in power plants and water systems.

Manufacturers are setting up local shops to cut shipping costs and meet regional needs. Getting the local rules and culture helps build trust with customers.

Partnering with Energy Companies

Valve makers and energy firms are teaming up more. They work together to build products for specific needs, like valves for solar plants or offshore wind farms.

These partnerships make sure products hit the mark for performance and green goals. Joint research sparks new ideas and builds stronger business bonds.

Using Data to Stay Ahead

Data from smart valve sensors is a lifesaver. It spots issues before they turn into big problems, cutting downtime. Repairs happen when they’re actually needed, not on a random schedule.

Data also shows how valves perform in real-world settings. Makers use this to tweak designs, like beefing up seals for high-pressure jobs. This keeps them ahead of the pack.

Wrapping It Up

In 2025, the valve industry’s got big hurdles but tons of potential. Supply chain fixes need more suppliers and smart tracking tools. Green rules mean investing in eco-friendly materials and certifications.

On the flip side, new markets are ripe for growth. Partnerships with energy companies fuel innovation. Data analytics makes maintenance and designs smarter. By tackling the tough stuff and grabbing opportunities with good valve company like Miwival, the valve industry can thrive in a greener, fast-changing energy world.

FAQ

Q: Why is the valve industry focusing on eco-friendly materials?

A: People are more concerned about the environment, and governments are setting strict rules on pollution. Valve makers are using recyclable metals and eco-friendly plastics to reduce their impact on the planet. Greener manufacturing methods also cut waste and energy use, which helps companies meet regulations and appeal to eco-conscious customers.

Q: What’s driving the demand for custom valves?

A: Industries like energy have unique needs, like handling corrosive chemicals or extreme heat. Companies want valves tailored to these specific jobs. Manufacturers work closely with clients and use advanced tools to design valves that fit perfectly, helping them stand out in specialized markets.