What Are the Standard Sizes for Pneumatic Operated Ball Valves?

Pneumatic operated ball valves are the type of quarter-turn valve that is operated by a pneumatic actuator. They are used to regulate fluid flow and consist of a ball with a hole through its center that can be rotated to allow or stop flow, depending on its position.

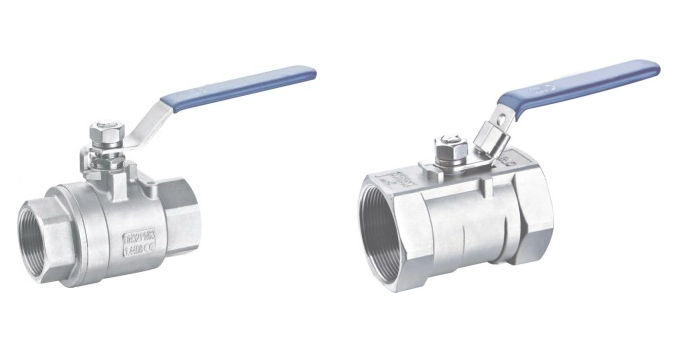

3 PC Ball Valve: Versatility in High and Low Pressure Use

3 PC ball valve is a common element of the mechanism used in various applications due to its design and function. It consists of the body, the ball, and the seats which are normally made from a range of high-quality materials like stainless steel or brass.

How to Choose the Right Stainless Steel Butterfly Valve for Your Needs?

The benefit of using stainless steel in a butterfly valve is its fantastic corrosion resistance, so it lasts a long time even in aggressive media.

Wafer Style Butterfly Valve Installation: Common Challenges & Solutions

Pipeline conditions have to be assessed for maintenance and care of wafer style butterfly valve.

Troubleshooting Tips for 3 Way Globe Valve: Common Issues Solved

The 3 way globe valve is a multi-purpose body and is suitable for various industrial applications to carry out many functions but widely it is used to control the flow of fluid with rotating actuation. With the ability to regulate, mix, or divert flow, its distinctive design is fundamental to any system with precise control. As a result, it is unique as it can be used to control, mix, or divert…

Proper Installation of Globe Valves for Flow Control: Expert Insights

Ensuring that proper flow control can be utilized through the use of globe valves is only possible with proper installation. Poor setup may also cause inefficiencies and cause the system to wear down and possible security threats. Globe valves are the type of valves that are purposefully designed to control the flow, and the precision placement of the valve is crucial for a functional globe valve to operate properly.

Step-by-Step Guide to Installing a Threaded Ball Valve Efficiently

Miwival threaded ball valves offer reliable performance that is highly resistant to leakage, thanks to features like self-adjusting stem seals, anti-static devices, and more. With features including self-adjusting stem seals and anti-static devices, Miwival threaded ball valves are dependable for leakage prevention and maintenance of efficient operation capability over their lifetime.

How to Choose the Right Stainless Ball Valve for Your Needs

Stainless steel ball valves are reliable industrial components that control the flows of acids and other materials in both saturated steam systems & condensed flow systems. These valves work with the help of a hollow, perforated, and rotating ball that controls the flow that goes through it.

Knife Gate Valve Options: Which Type Suits Your Industrial Needs?

Knife gate valves for tough applications in industry These are mainly used to regulate the media passage like slurry, powder, or granules through sharp-edged gates that slice through the medium. Knife gate valves are highly efficient and simple in design which facilitates their selection by industries that need to handle thick or aggressive materials.

Unveiling the Secrets of Knife Gate Valve Performance

In industrial applications where fluid flow needs to be controlled or shut off, knife gate valves are a fundamental feature. They are specially designed for applications that involve suspended solids or media with particulates, so they have applications in the mining industry, wastewater, and chemical processing industries.

Why V Port Segmented Ball Valves are Key to Efficient Liquid and Gas Flow

V Port Segmented Ball Valves are an important part of fluid control systems that find extensive application across industry verticals. Their design allows you to manage both fluid and gas flow, thus ensuring a greater level of efficiency and reliability in the process.

Segmented Ball Valve Basics: Key Features and Operational Mechanisms

A segmented ball valve is a valve that has a disc-shaped segment of a V notch on its shoulder. As a result, the flow rate and pressure in different systems can be precisely adjusted. A segmented ball valve is mainly used for flow regulating and has a very low operating torque requirement thus becoming an ideal solution for performing applications where guiding the dynamics of fluid is essential.