I. Structure of Y-Type Strainers

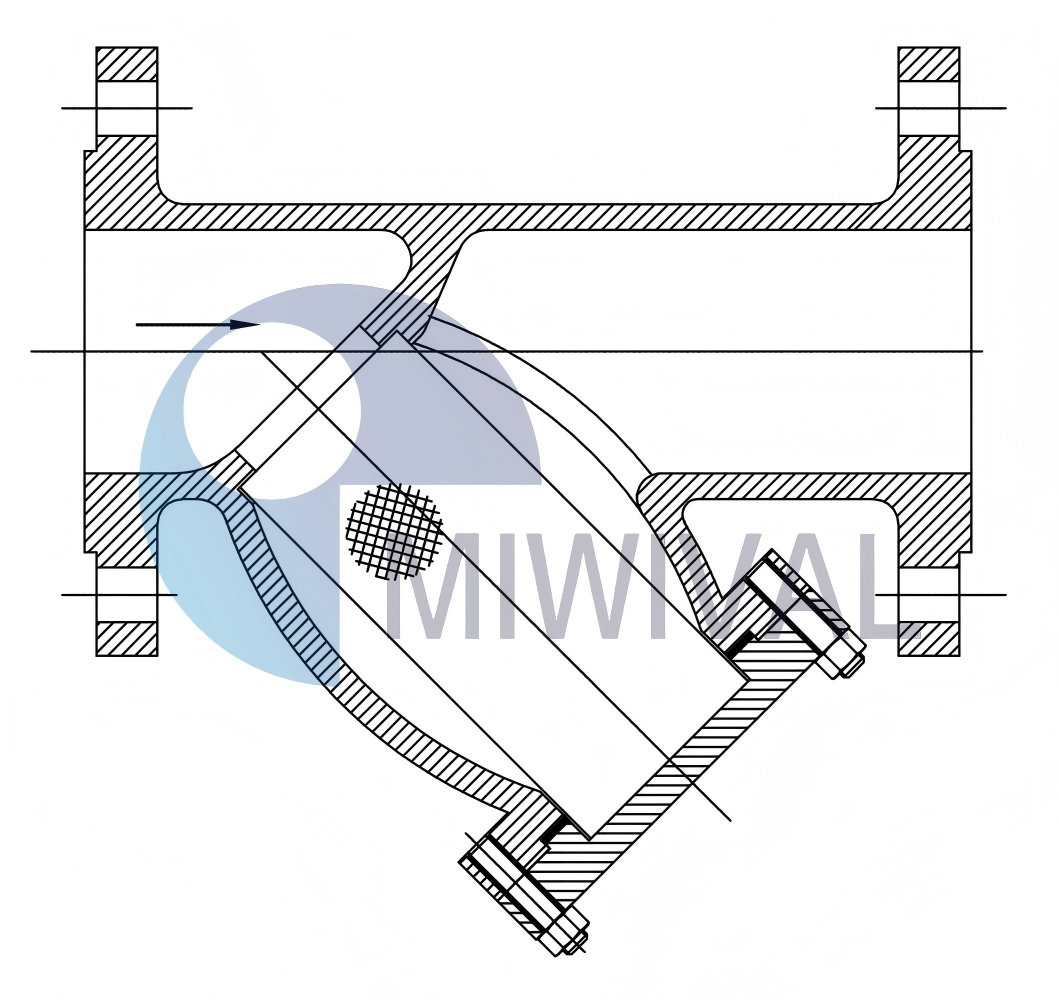

Y-type strainers are straight-through filtration devices, named for their “Y” shape, and consist of following components:

1. Main Valve Body: Y-shaped flow channel, including inlet, outlet, and drain ports. The materialsvaryfrom cast iron, carbon steel, stainless steel, copper alloy, etc., depending on the working conditions;

2. Filter Screen: Installed in the Y-shaped branch pipe, it’s the core filtering component. Mostly use stainless steel (corrosion-resistant and easy to clean), with filtration accuracy ranging from 20 meshto 1000 mesh;

3. Drain Bonnet/Valve: The sealing component at the bottom of the Y-shape, which can be manually removed (bolt-fastened) or equipped with a drain valve (ball valve/gate valve) for cleaning retained impurities;

4. Seals: Sealing structures at the valve body and drain cover/filter screen interfaces, made of NBR, Viton, or PTFE, ensuring no leakage.

II. Working Principle

Medium flows into the valve body from the inlet, most of it flows directly to the outlet along the main channel, while a small amount of medium containing impurities enters the filter screen chamber of the Y-shaped branch pipe:

1. The filter screen intercepts solid particles in the medium (such as sand, rust, and welding slag), and the clean medium passes through the filter screen back to the main channel;

2. The retained impurities are deposited at the bottom of strainersand discharged by regularly opening the drain bonnet/valve, or by backwashing the filter screen with a backwashing device;

3. The entire process does not require shutting down and disassembling the main body; cleaning can be completed simply by operating the drain port, without affecting the continuous operation of the pipeline system.

III. Core Features

1. Compact Structure: Small size, light weight, low installation space requirements, and can be installed horizontally/vertically;

2. Strong Flow Capacity: Straight-through flow channel design, low pressure loss (resistance coefficient usually <1.5), and minimal impact on pipeline flow;

3. Convenient Maintenance: No need to disassemble the valve body; the filter screen can be cleaned by simply opening the drain port, resulting in low maintenance costs;

4. Wide Adaptability: Material, precision, and diameter are optional, meeting the requirements of different media, pressures, and temperatures;

5. Low Cost: Compared with basket and bag strainers, thecost is lower.

IV. Applications

Y-type strainers are the most commonly used general-purpose filtration equipment in industry.

1. Water Supply and Drainage Systems

(1) Tap water transportation, central air conditioning circulating water, heating pipelines: Filtering sand and rust, protecting water pumps, heat exchangers, and radiators, preventing blockages;

(2) Pre-treatment in sewage treatment plants: Intercepting large suspended solids, protecting subsequent precision filtration equipment.

2. Petrochemical Industry

(1) Crude oil and refined oil transportation pipelines: Filtering welding slag and solid particles in the pipeline, protecting flow meters, control valves, and oil pumps;

(2) Chemical raw material (acid, alkali, solvent) transportation: Using stainless steel materials to filter impurities and prevent damage to reactors and precision instruments.

3. Gas Systems

Natural gas, liquefied gas, and city gas pipelines: Filtering tar and dust, protecting pressure regulators and gas meters, and preventing gas equipment malfunctions.

4. Food and Pharmaceutical Industries

(1) Beverage and dairy product production pipelines: Using sanitary-grade stainless steel (316L) to filter impurities in raw materials, meeting food hygiene standards;

(2) Pre-treatment of pharmaceutical water: Filtering suspended solids in water, providing protection for subsequent reverse osmosis and purified water equipment.

5. Industrial Equipment Accessories

(1) Hydraulic and lubrication systems: Filters remove metal debris and impurities from the fluid, protecting precision components such as hydraulic pumps and bearings;

(2) Air compressor and compressor intake/exhaust pipes: Filters remove dust, extending the service life of the equipment.