What Are the Key Advantages of Using a Forged Globe Valve

Forged globe valves provide precise flow control, high reliability, and low maintenance for demanding industries like petroleum and power.

Things You Need to Know About Lined Globe Control Valves

Lined globe control valves: corrosion-resistant, precise flow control for chemical, oil & gas, and water treatment.

How to Choose Between a Knife Valve and a Gate Valve for Your Application

Knife gate vs. gate valves: Learn which is best for your media, conditions, and budget in mining, wastewater, and oil applications.

Applications of Flow Control Valves in Industrial Processes

Flow control valves regulate liquids, gases, and air in water treatment, chemical processing, and HVAC, improving efficiency and performance

Comparing Swing and Lift Check Valves: Functional Differences Explained

Compare Swing and Lift Check Valves: learn their key differences in design, performance, and ideal applications.

How to Pick Between Ball Valves and Gate Valves for Your Needs

Learn how to choose between ball valves and gate valves. Compare their design, performance, and applications to find the best fit for your industrial needs.

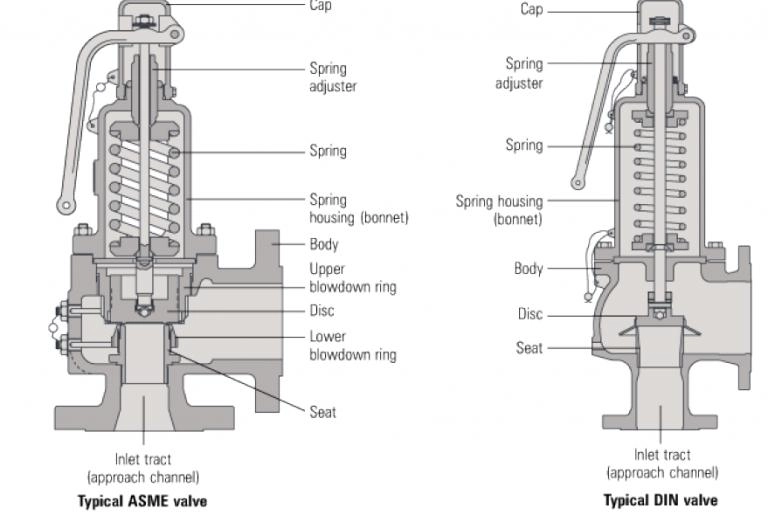

Industry Insights into the Standards of the Pressure Relief Valve

Discover the pressure relief valve, its key components, applications, and Miwival’s commitment to safety, efficiency, and reliability.

How Material Choices Influence the Price of a Gate Valve

Learn how material choices affect the price of 1/2 gate valves, from stainless steel to PVC, and explore Miwival's reliable options for different needs.

Factors to Consider When Selecting the Right Control Valve

Control valves are vital in operations as they control the flow rate and temperature of fluids to ensure efficiency and safety in system conditions.

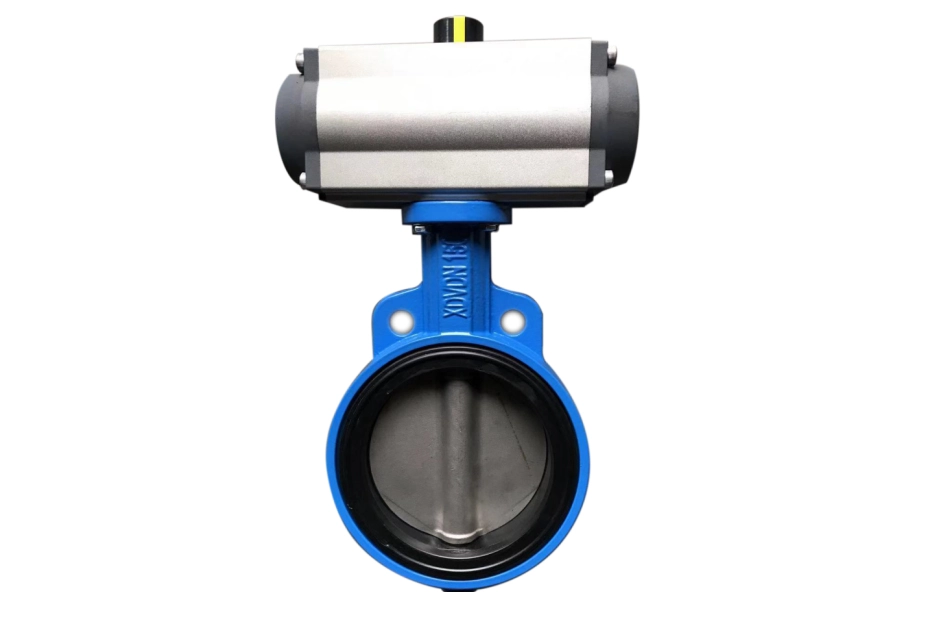

How Butterfly Valves Regulate Flow in Industrial Applications

Butterfly valves are often utilized in settings to manage fluid flow by regulating or blocking it using a rotating disc within a pipe system known for being light, in weight, and cost-effective when compared to alternative valve options.

Understanding Gate Valve Mechanisms and Their Industrial Applications

Gate valves are extensively utilized in a range of industries as one of the most popular valve types due to their reputation for creating a secure seal and efficiently regulating fluid flow, in both industrial and domestic settings.

.webp)